Technology has made a significant contribution to the evolution of almost all sectors including textile, automotive, transportation, hospitality etc, in terms of automating and easing manual work.

The role of technology in the textile industry has not only simplified the techniques involved but also enhanced the business toa new level. Technologies such as digital printing, textile machinery, business analysis etc. has helped this industry grow rapidly in the past few years. We will be discussing the evolution of technology in the textile domain and how it has affected the growth of the same. The textile industry primarily includes development and distribution of textiles such as yarn, synthetic clothing, wools etc. and we will discuss how it has enhanced because of the emerging technology.

How Technology In Textile Industry Has Evolved In The Last Few Year

Technology has affected the textile industry in more ways than we know with various modern tech like artificial intelligence, automation, business intelligence, etc. Automation has reduced the human efforts in the development of designs and textiles whereas artificial intelligence has helped in improving the process involved. Let’s understand how these technologies have impacted textile development in detail.

Automation

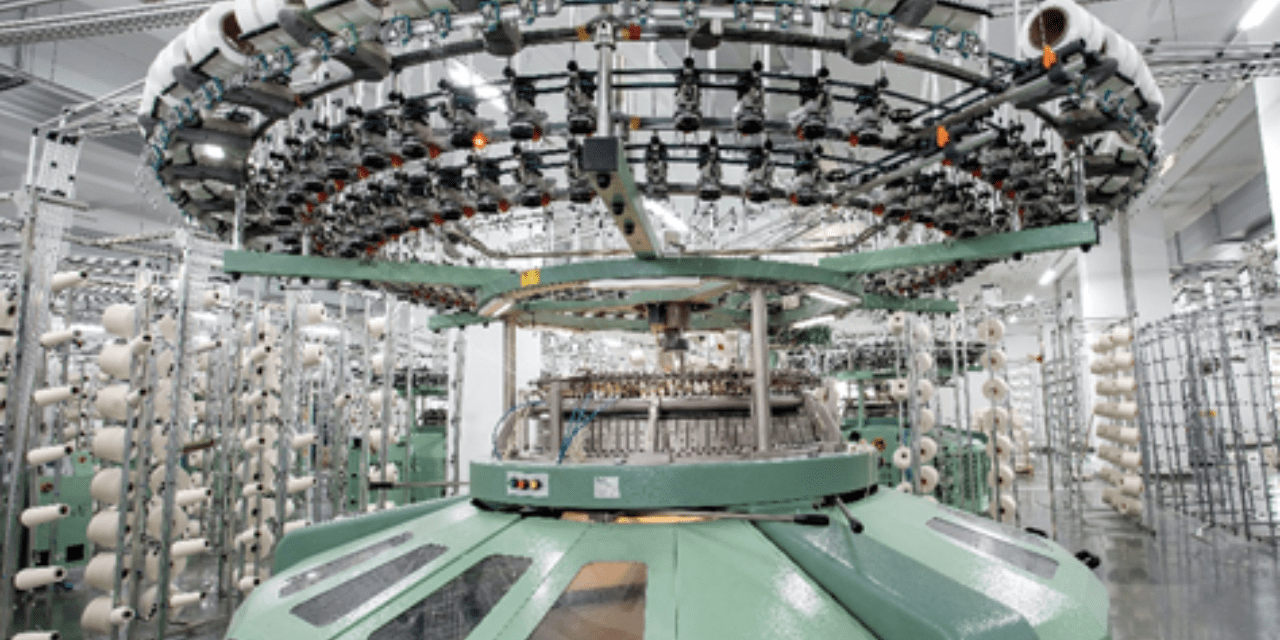

Automation has been one of the major contributors towards the increase in productivity and efficiency of tegh processes involved in textile manufacturing. The chances of error of an automated process are way less than the error done by a manual effort. Automation of textile-related processes also reduces the possibility of fatigue and breaks as the major work is done by machines only. The speed at which the machines work is also significantly higher as compared to some manual work which also increases the efficiency as well as productivity of the same task.

The inventory turnover in the textile industry has also increased at a significant level after the automation has been introduced. This is eventually linked with the increase in productivity as increase in pace of manufacturing calls for more raw materials, tools, cut components, etc. From a business perspective, automation has also helped the textile companies save the human labor cost as human work is replaced by the machines which has a significantly lesser cost in the long run. However the initial cost of installation and maintenance of the machinery is very high but the result obtained is considerably better in terms of efficiency and accuracy.

Artificial Intelligence (AI)

If automation has reduced human work and introduced the machined process in textile industries, AI has improved the way these machines work. AI has changed almost every aspect of the textile industry whether it is the fabrication of the textile, quality control, testing of materials or data collection. AI has not only enhanced some machine techniques but has also helped in introducing new processes that were done manually such as fault detection, pattern checking, and color matching, which are crucial in the textile industry.

Apart from playing a vital role in textile development, the technology developed because AI is now also being used in clothes making them “Smart clothes”. These clothes have features such as electronic sensors that are IoT enabled which has made the textile business more innovative than ever.

There are certain processes that have been majorly affected by the implementation of AI in the textile industry such as Yarn Manufacturing, fabric inspection, color management etc. From drawing laps to combing the yarn, every step of yarn manufacturing has been enhanced with AI as the system is able to identify patterns and colors for manufacturing. AI has reduced mistakes done during yarn manufacturing by 60%. AI has also made it easier to detect any faults in the fabric pattern which has reduced the error rate in textile development by a significant level.

Benefits and Drawbacks of Using Technology in the Textile Industry

To understand the impact of technology in the textile industry, it is important to analyze both, their benefits and drawbacks. Here are some of the major merits and demerits of using modern tech to transform the textile domain.

Benefits

Reduced Working Hours: Automation has helped workers to do more work in less time because of which they are able to produce more fabrics and their working hours have been reduced to a great extent. Even if the distribution of the textiles is considered, it has been very easy for international e-commerce websites like Ubuy India around the globe to control the supply chain resulting in reduced distribution hours.

Increased Security: There are a lot of health threatening processes that are involved in textile manufacturing like coloring, dyeing, spinning and weaving. When these processes were done manually, there were a lot of threats attached to them such as the toxicity of dyes, and injuries while spinning and weaving. But the inclusion of automation and AI has allowed machines to do these tasks increasing the safety of the employees working at the factory.

Drawbacks

Unemployment: This is one of the major disadvantages of including technologies in the textile domain. The amount of workforce was reduced after the inclusion of automated machines as most of the work is done by machines only. However, there are people who are responsible for operating the machines, but the workforce needed for this is very low as compared to earlier when this was done manually.

High Investment: The initial cost of machines is very high which is why some small-scale companies avoid investing in machinery at the initial stage. The tools required for the maintenance of the machine are also an added cost included in the process which makes it even more expensive.

Future of Technology in Textile

One of the most recent advancements to look out for in the textile industry in terms of technology is Near Field Communication (NFC). NFC interactive clothing is a textile tech that is expected to change the retail face by getting ideas for styling a dress as soon as you hover your phone over its tag with.

Apart from this, there are various other domains in which new technologies in textiles can be used such as artificial turfs in sports, cotton canvas in building techs, bolting cloths for geotech and many more. It is anticipated in future that new technologies such as IoT, Augmented Reality and 6G and other future trends can also be implemented even more in the textile industry.

By: Fahad Khan, Product Manager at Ubuy