S. Lavate, P. V. Kadole, M.B. Bhongle

D.K.T.E. Society’s Textile and Engineering Institute, Ichalkaranji (MH), India-416115.

Email: mukeshbhongle@gmail.com

Abstract

Ring spinning is the most popular and universal spinning system due to its significant advantages in comparison with the new spinning systems. But the yarn properties are hampered in ring spinning system with the increase of spindle speed and spinning triangle. Overall yarn properties can be improved by retrofitting conventional ring spinning machine. It also ensures better yarn properties such as strength & elongation, unevenness %, imperfections, hairiness etc. The 40S Ne of Bamboo: Polyester :: 35:65 Proportion was manufactured on four different spinning systems viz. Ring spinning, Siro spinning, Compact spinning, Compact-Siro spinning system. It is observed that compact yarn and siro yarn are stronger and less hairy due to the improved fibre binding, and have better yarn elongation, yarn irregularity and IPI values compared with conventional ring yarns. Compact-Siro yarn combines the benefits of both the systems.

Keywords: Bamboo, Compact, Polyester, Ring, Siro, Compact-Siro yarn.

- Introduction

Blending is the process of combining different fibres together intimately to achieve a desired product characteristics. Blends can influence colouring, strength, softness, absorbency, ease of washing, resistance to wrinkling, ease of spinning, cost, etc.

Natural fibres and their blends bear valuable properties. At present there are various products made of bamboo Fibres work on characteristics by better provide absorbtion and desorption of moisture, no irritation, antibacterial, anti-allergic, protection against the harmful UV rays and other valuable properties. Bamboo and polyester can be blended to get desirable combination of properties in the end product, by random mixing of staple fibres is the most common practice. Ring spun yarns made from 50/50 cotton/bamboo concluded that hairiness of bamboo yarns is much lower than that of equivalent cotton yarns. The tenacity of yarns spun from 50/50 cotton/bamboo blended spun yarns tenacity is lower and yarn unevenness is higher than that of 100% cotton and bamboo . The effect of blend ratio on with compare with 100% cotton yarn quality characteristics of bamboo/cotton blended ring spun yarns of linear density concluded that increase in ratio of bamboo/cotton blended yarn has a significant influence on the overall quality of yarn in terms of imperfection and mechanical properties such as strength and elongation, linear density of yarns.It is found that functional properties of bamboo blended knitted apparel fabrics concluded that bamboo content of yarn increases the yarn hairiness and unevenness increase along with a decrease tenacity during spinning of polyester/bamboo blended yarn with appropriate drafting system in order achieve proper integration of fibers in yarn and to achieve better yarn properties.

Comfort is one of the most important aspects of fabrics. Yarns made of staple fibres have the additional complexity of the discontinuities at the fibre ends and the difference in structures due to the difference in spinning technologies. Different spinning technologies such as a ring, compact and Siro spinning have potential for higher productivity and also influence the yarn characteristics significantly. Yarn properties are having a strong correlation with fabric properties. Hence, yarn manufactured on different spinning technologies are exhibiting variable effects in fabric characteristic.

Hence it is worth to study the effect of different spinning technologies on characteristics of yarn. This investigation is helpful for the spinner as well as a weaver to engineer their products as per the consumer demand.

- Materials and Method

In this study Bamboo and polyester Fibres of following specification were used for making yarns.

Bamboo Fibres staple length: – 38 mm, denier: – 1.2

Polyester Fibres staple length: – 44 mm, denier: – 1.4.

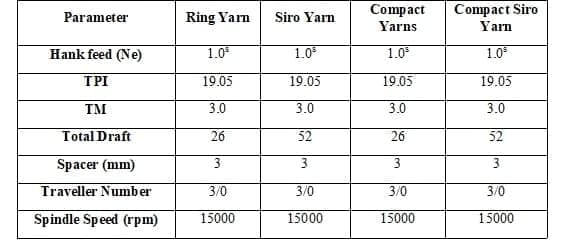

The 40s Ne bamboo-polyester blended spun yarns with ratio 35:65 were manufactured on four different spinning systems viz. Ring spinning, Siro spinning, Compact spinning, Compact-Siro spinning system. The yarn samples were characterized for the linear density of yarn, single yarn strength & elongation, count strength product, evenness & imperfection, hairiness & wicking behaviour. The results obtained were analyzed by one-way analysis of variance. Yarn manufacturing (spinning) parameters are given in table 1.

Table 1 Yarn Manufacturing (Spinning) Parameters

- Results and Discussion

The results obtained on various tests were statically analyzed which are discussed as follows.

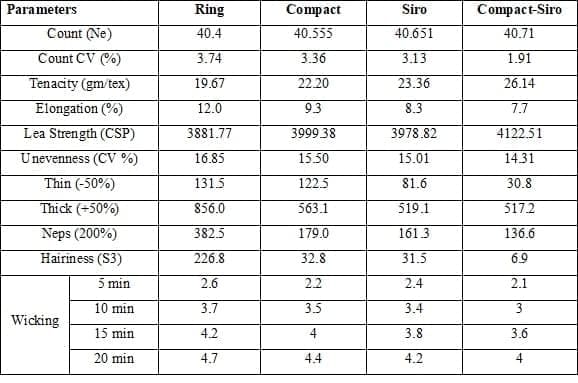

The results obtained on different tests have been summarized the table 2.

3.1 Yarn Count CV (%)

The count CV% value which directly relates the presence of long term irregularity. The statistical analysis shows that there is no significant difference in the counts spun on various spinning system, compact siro spun yarn exhibits lower count CV% value followed by siro, compact and ring yarn respectively.

3.2 Yarn Tensile Properties

Effect of spinning technology on tenacity and elongation of Bamboo-Polyester blended yarn is shown in figure 1.

Figure 1 Yarn Strength and Elongation Figure 2 Lea Strength

It is observed that Compact-Siro yarn shows highest amongst all the yarns followed by Compact, Siro and Ring respectively. Ring yarn is shows lowest strength. However, ring yarn shows the highest elongation at break. In ring spinning first the size of the roving is reduced to the desired yarn count by drafting. At the same time the roving twist is removed to a large extent and cohesion within the fibres is mainly lost. Thus the individual fibres lie relatively far apart from each other when they reach the delivery clamping line. This leads to increased elongation and decreased strength. Compact-Siro yarn combines the benefits of both the systems giving stronger yarn with slightly less elongation [6, 7].

Lea Strength

Lea strength of Bamboo-Polyester blended yarn was determined in terms of count strength product. The effect of spinning technology on lea strength of yarn is shown in figure 2.

It is observed that there is significant effect of spinning technology on lea strength of yarn which is shown in figure 2. It can be seen from above figure that, lea strength of Compact-Siro yarn is highest amongst all the yarns followed by Compact, Siro and Ring respectively. Ring yarn is showing lowest lea strength amongst rest of the samples. It is also observed that there is correlation between single fibre and lea strength.

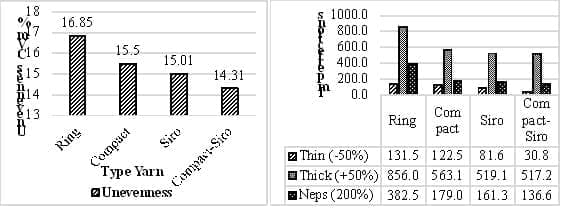

3.3 Yarn Unevenness, Imperfections and Hairiness

Effect of spinning technology on unevenness and imperfections of Bamboo-Polyester blended yarn is shown in figure 3 and figure 4 respectively. There is significant effect of spinning technology on yarn evenness and the imperfections. It can be seen from the fig 3 that CVm% is less in Compact-Siro spun yarn followed by Compact, Siro and ring yarn. The same trend is also observed for imperfections.

Figure 3 Unevenness % Figure 4 Imperfections

In ring spinning, the spinning triangle is the most troublesome and weakest zone in the yarn formation process in ring spinning as it increases end breakage, fiber loss and yarn hairiness. Hence ring spun yarn shows high values of CVm% and imperfections. In compact spinning the negative influence of the spinning triangle is minimized which reduces affects which reduces the unevenness and imperfections.

In case of Siro yarn there are better chances of readjustment of fibers due to doubling between the fleeces within the yarn leading to better evenness and reduced imperfections. Compact- Siro yarn combines the advantages of both Compact and Siro spinning system showing greater yarn evenness and lesser imperfections.

Yarn hairiness was calculated in terms of S3 value. S3 value indicates the sum of lengths of hairs longer than 3mm. The effect of spinning technology on hairiness of Bamboo-Polyester blended yarn is shown in figure 5. There is a significant effect of spinning technology on yarn hairiness. It is observed that hairiness of Compact-Siro yarn is lowermost with S3 value 6.9 followed by Compact, Siro and Ring yarn structure.

The main reason for this could be attributed to the fact that two roving strands are separately drafted and twisted to a certain extent before uniting, which greatly limits the extent of protruding fibers. Hence it is showing less hairiness than ring spun yarn. Cross-section of Compact-Siro spun yarn is smoother and closer to being circular which is beneficial for spun yarn qualities, especially for improving the yarn evenness and hairiness.

The wickability of yarn manufactured on different spinning systems was determined in terms of rise of wicking solution with respect to time which is shown in figure 6.

There is a significant effect of spinning technology on yarn wicking. It can be seen that, wickability of Compact-Siro yarn is lowermost followed by Compact, Siro and Ring. As compared to Compact, Siro or Compact-Siro yarn, ring yarn has open packing. Open packing forms micro capillaries which are responsible for wicking action hence ring yarn shows high wickability. Compact-Siro yarn has even more close packing than Siro yarn resulting lower wicking ability.

- Conclusion

Compact yarn and Siro yarn are claimed to be stronger and less hairy due to the improved fibre binding, and have better yarn in strength & elongation, yarn irregularity and IPI values compared with conventional ring yarns.In case of compact yarn, the spinning triangle is very small which leads to better twisting of edge fibres, resulting inthe higher number of fibres in yarn cross section. As a number of fibres in yarn cross-section increases, there is an increase in load bearing component in yarn. In Siro yarn, the majority of the fibres get trapped in the structure so as to increase inter-fibre cohesion in the yarn, thus making the yarn withstand higher breaking forces. Compact-Siro yarn combines the benefits of both the systems. It is possible to use low quality fibres while maintaining yarn strength equal to the conventional ring spun yarn with the same twist level.

- References

- Majumdar A., & Mukhopadhyay S., “Properties of ring-spun yarns made from cotton and regenerated bamboo fibres”, IJFTR, Vol. 36, No.1, March 2011, 18-23.

- Prakash C., Ramakrishnan G., & Koushik , “Effect of Blend Ratio on the Quality Characteristics of Bamboo/Cotton Blended Ring Spun Yarn”, Fibres & Textiles in Eastern Europe, Vol. 19, No. 6, 2011, P. 38-40.

- Sudipta S mahish, A K patra and Rashami Thakur, Functional properties of bamboo/polyester blended knitted fabrics, IJFTR, Vol 37, Sept 2012, pp.231-237.

- Barodia H. D. and Khare A.R., “Some variations in Siro spinning”, The Indian Textile Journal, May 2012 https://www.indiantextilejournal.com/articles/FAdetails.asp?id=4489

- Xuzhong Su, Weidong Gao, Xinjin Liu, Chunping Xie, Bojun Xu, “Research on the Compact-Siro Spun Yarn Structure”, Fibres & Textiles in Eastern Europe, Vol. 3, 2015, P.54-57.

- Iqbal SMF, “Influence of yarn structure produced in different spinning systems on the properties of yarn”, IJAR, Vol.4, No.4, 2018, P.172-176.

- Cheng K.P.S, Yuen C.H., “Siro And Two-Fold Yarns”, Research Journal of Textile and Apparel, Vol. 1, No.1, 1997, P.64-70, https://doi.org/10.1108/RJTA-01-01-1997-B008.

- Sharma I. C., Pandey A., Janveja A., Sharma N., “Comparison of Properties of Siro spun and conventional two fold yarns and of their fabrics”,Indian Journal of Textile Research, Vol. 11, 1986, P.15-18.

- Advantages of bamboo yarn and bamboo fabric, bambrotex.com, (Accessed on 01/01/2017).

- Stalder H. and Rusch A., “Successful compact spinning process”, Intl. Textile Bulletin., Vol. 48, No.1,2002, P 42-43.

- Stalder H., “A new spinning process – ComforSpin”, Melliand Textilber., Vol.80, No.3, 2000, P.133-135.

- EliTe CompactSet V5, Suessen brochure leaflets, https://www.suessen.com.

- Artzt P., “The effect of different spinning processes on yarns”, ITB, Vol.49, 2003, P. 40-43.

- Sundaresan S., Balu R., & Mohanraj R., “Effect of Strand spacing of SIRO Compact yarn on fabric properties”, Vol. 2, No. 4, 2016, P. 172-179.

- Long Li & Hongqin Yan, “Tensile Properties of Regenerated Bamboo Yarn” Fibres & Textiles in Eastern Europe, Vol. 20, No. 1, 2012, P.18-23.