Remscheid, Germany / Hebi (Henan Province), China, November 7, 2024 Twelve locations of an eight-end tire yarn factory from Oerlikon Barmag have been put into service by Sinowin Chemical Fibers, the first PA66 industrial yarn manufacturer in the Chinese province of Henan.

The airbag and tire yarn specialist is thus reaffirming its commitment to the growth market of automotive textiles. The 8-end concept, which is unique on the market, scores above all with its energy efficiency and cost-effectiveness. “We believe in the automotive market and its growth opportunities. We believe that industrial yarn has great potential,” says Chen Haitao, President of Sinowin. “The automotive industry has extremely high-quality standards. We can reliably meet these requirements with our products, not least because we attach great importance to the quality of our production facilities.”

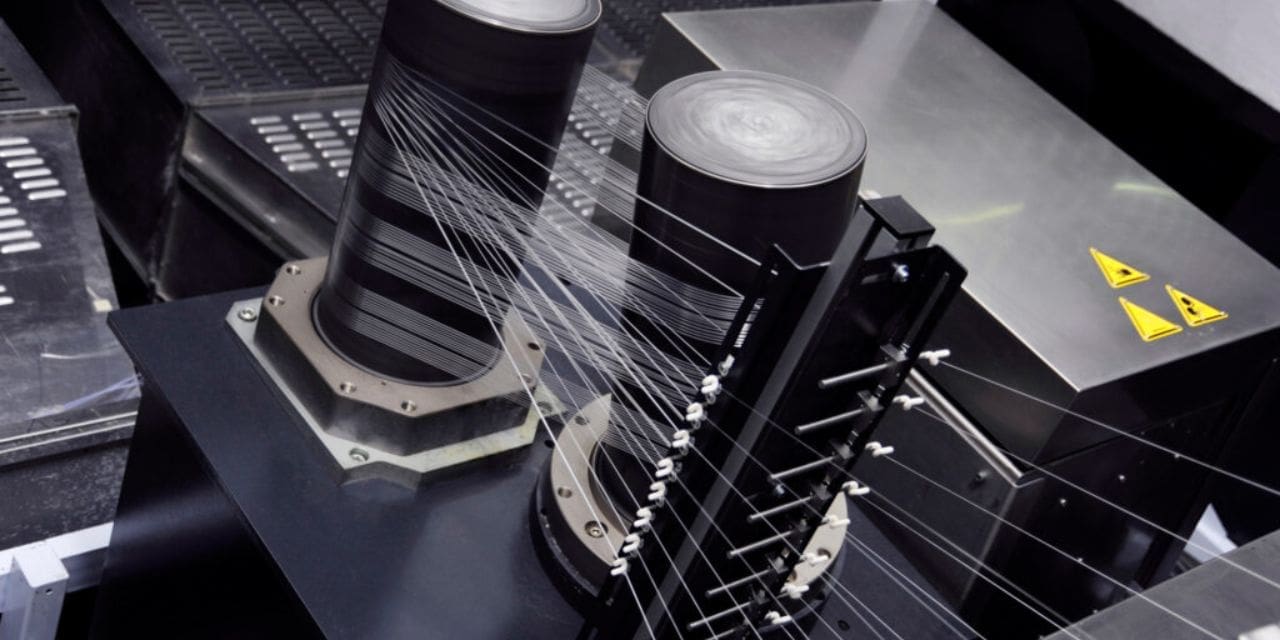

Since its founding in 2015, the business has relied on Oerlikon Barmag technology. The PA66 specialist has now increased its capacity to 44 positions from its initial 10 positions. There are currently plans for more diversification and capacity increase. “We aim to cover every step of the tire yarn production process, including dipping, weaving, cabling, and spinning. the tire’s whole textile component from a single vendor. Regarding his company’s future plans, Chen Haitao states that this will greatly increase the transparency of the tire supply chain.