The leading nonwoven line manufacturer Reifenhäuser Reicofil, a division of the Reifenhäuser Group, will debut its new RF5 XHL production platform at the premier international nonwovens trade show INDEX 23 in Geneva from April 18 to 21 (booth 1531).

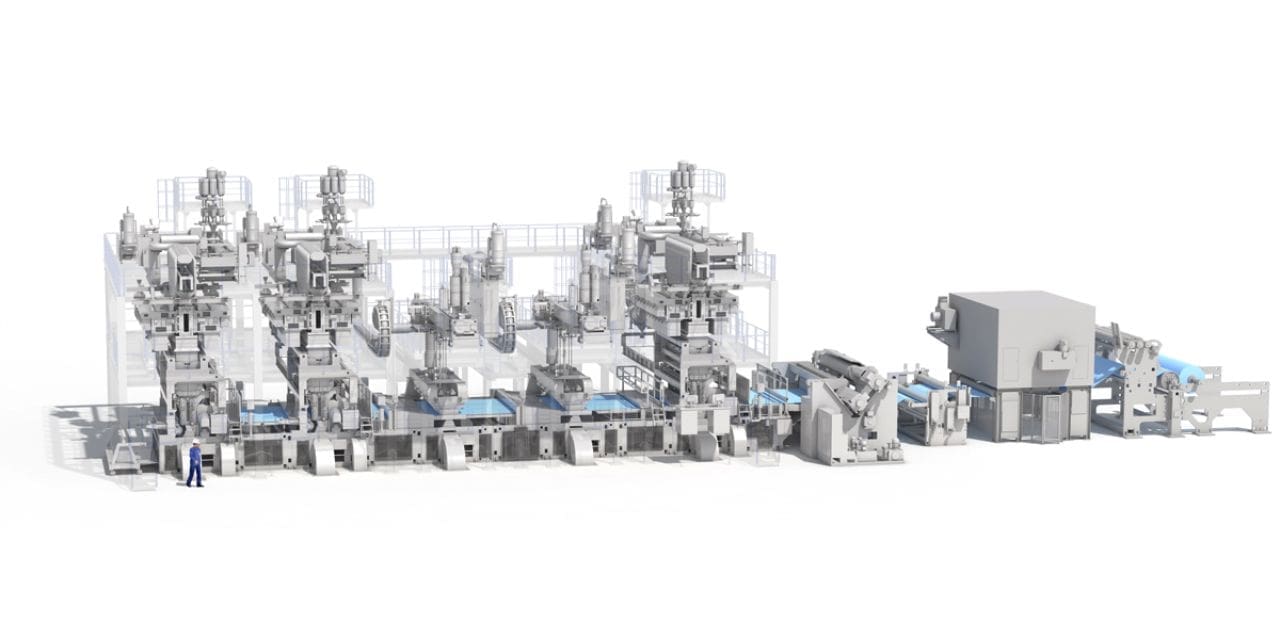

Extra High Loft is the meaning of the suffix XHL. The RF5 XHL technology, aimed at extremely soft and drapeable nonwovens for the hygiene industry, is an advancement of the well-proven RF5 technology. According to Markus Müller, Vice President Sales & Marketing of the Reifenhäuser Group, “Our XHL nonwovens offer a new level of quality with super soft touch for nonwoven products made from them – such as top sheet and back sheet.” simultaneously, we accomplish a significant reduction in resource use that can minimise the carbon footprint by up to 30%.The specifically patented BiCo method is the foundation of the RF5 XHL technology. In the spunbond process, this mixes two separate source materials into a single fibre, producing a bimetallic effect and optimally crimping the fibre. As a result, weight can be reduced by up to 25% for fibre sizes at 1.0 denier. At the same time, thickness rises up to 30% in comparison to material that is state-of-the-art.

Additionally, the new RF5 XHL lines have highly energy-efficient parts that allow for high line speeds and resource-saving nonwoven production. All raw materials are made of polypropylene (PP) enabling quick and easy inline recycling, minimising production waste. When compared, It is exceedingly challenging to recycle popular mixed-material fabrics consisting of PP/PE or PET/PE. Additionally, RF5 lines process bio-based raw materials upon request in order to satisfy the ongoing need for more environmentally friendly nonwoven goods.

With the help of c.Hub, the Reifenhäuser Group’s brand-new data connection platform, Reicofil is able to provide customers with a digitalization solution that is consistently adapted to the needs of the nonwovens industry. Customers have the option to use the c.Hub middleware to securely network the data from their Reicofil lines, peripherals, and ERP and MES systems, storing it centrally for quick analysis. Thus, line operators may keep track of their production, record it, and improve production efficiency using data. The on-premise solution c.Hub is supplied with a variety of software bundles, so it can be run locally and maintain the user’s complete data sovereignty.

Enka Tecnica offers a cost-effective alternative to new parts with its refurbishment service for old components. Additionally, it provides incredibly quick delivery times, which is frequently essential to meet daily production goals. Visitors to Geneva will be able to examine the high calibre of refurbished parts on exhibit at the stand, which includes a meltblown and a spunbond spinneret that has been renovated to a certain extent. Through the use of a microscope, they will be able to compare the before-and-after conditions of the capillary holes.