The wide-ranging implications of the linear “make and discard” model have had a significant impact on climate change and environmental degradation. Less than 1% of garments are currently being recycled, resulting in over 70% of the world’s clothing ending up in landfills. In light of this, regenerated fibers play a crucial role in promoting the circular economy and closing the loop. Recycling textiles offers numerous benefits, including a 70% reduction in energy consumption, 75% decrease in CO2 emissions, and an 86% decrease in water usage compared to using virgin fabrics.

For years, spinners have relied on LMW machines to harness the advantages of spinning recycled fibers from various raw materials such as PET bottles and fabric cut waste. LMW’s spinning line enables the production of yarn from recycled materials up to a count of 40 Ne, with a blend ratio of 80% pre and post-consumer waste material and

20% virgin cotton

Autoblend – Automatic mixing of different material

The Gentle Blowroom line from LMW ensures efficient opening and cleaning, effective microdust extraction, optimal blending of fibers, and continuous feed to the Card.

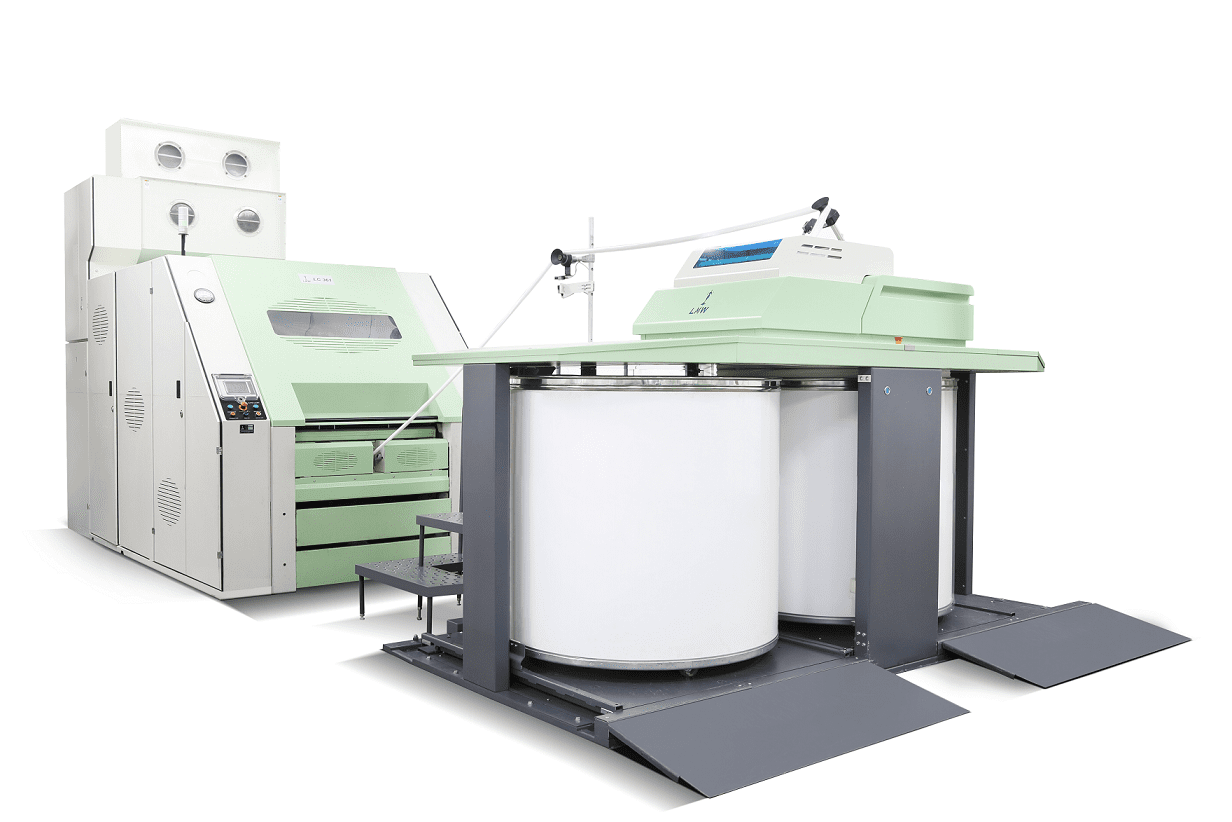

Card with CDS

The Card LC363/OE facilitates higher production rates, consistent quality, reduced lint loss, lower power consumption, and high realization. Higher number of working flats and 3 lickerin arrangement ensures effective opening of fibre clusters or unopened cloth.

Combing segment below the lickerin arrangement along with Suction system arrangement and gravity falling of waste helps to remove any cloth bits / foreign matters effectively without loosing good fibres.

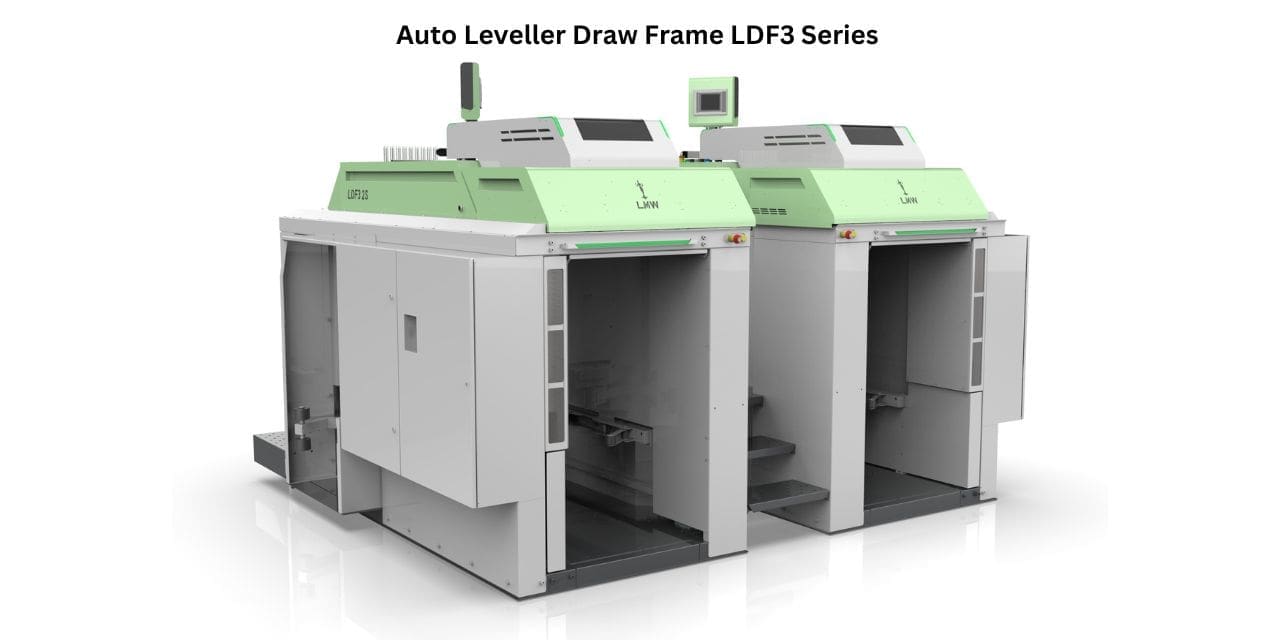

The precise Autolevelling Draw Frame LDF3 E supports increased production with superior quality through features such as Duo Digital Auto Levelling, a Change Gearless drive system, and Auto piecing.

LMW Smart series machines are highly suitable for mechanical recycling and have gained popularity with over 150 recycling installations worldwide.

Over 500 cards from LMW are currently operating successfully in various recycling clusters contributing to a total production volume of 32.67 lakh tons per year, complemented by LMW Gentle Blowroom machinery. The LMW Smart Ring Frame, combined with the most suitable preparatory machines for Ring spinning and Open End applications, effectively produces recycled yarn.

Fostering Eco-sensitive Success with benchmarking standards

Reysan Iplik, İstanbul, Türkiye, with its fixed and unchanging commitment towards environment first approach is successfully achieving counts up to 20s Ne for a blend ratio of 90% Regenerated Fibre and 10% Polyester on LMW preparatory machines.

Camci Tekstil, Uşak, Türkiye, leading by example with its environment sensitive approach is spinning counts up to 20s Ne for a blend ratio of 70% Regenerated Fibre and 30% Polyester on LMW preparatory machines.

Vardhman ReNova, the fiber recycling plant of Vardhman Group, India, boasts a production capacity of 6 TPD and is designed to recycle Yarn Hard Waste/Fabric Clippings into usable fiber. Equipped with LMW Smart machines, the Vardhman Group mills have successfully facilitated the spinning of recycled yarns with counts like 24s Ne and 30s Ne, using a blend ratio of 30% recycled cotton, 40% recycled polyester, and 30% virgin cotton. To demonstrate the quality and applicability of the ring yarn spun from recycled material, LMW conducted a pilot project manufacturing T-shirts made from recycled yarn and presented them to the entire customer base during ITME 2022 at India and ITMA 2023 at Milan for widespread use.

Kanchan India Limited, based in Rajasthan, India is dedicated to sustainable production and actively manufactures recycled yarns in response to the growing market demand. LMW machines are used at Kanchan India Limited to produce recycled yarns from recycled PET bottle fiber and fabric cut waste.

LMW’s commitment to sustainability has led to a collaboration with Madura Coats for the commissioning of the A-Z pilot project “Coats Sustainability Hub” in Madurai. This Sustainability Hub will accelerate the transition to recycled and renewable materials, support customers and stakeholders in creating sustainability within the industry, drive sustainability innovation, enhance brand collaborations, and facilitate the rapid development and introduction of sustainable products to the market.

The transformation of the textile value chain to align with the guiding principles of the circular economy is already underway, and as a pioneer in textile technology, LMW will play a crucial role in this transformation process.

At LMW, Sustainability is a way of life …