Stäubli is a global player in the weaving industry, renowned for solutions that bring real customer benefits like energy savings and efficiency in weaving and warp preparation. Our product range allows weavers to manufacture more first-quality product and to waste less raw material. What’s more, we provide machines that enable weaving mills to produce new types of technical fabrics that enhance daily life worldwide in sectors ranging from medicine to transportation, aerospace, and others. Find out more at our Stand B01/Hall 12 under the roof of the Swissmem stand.

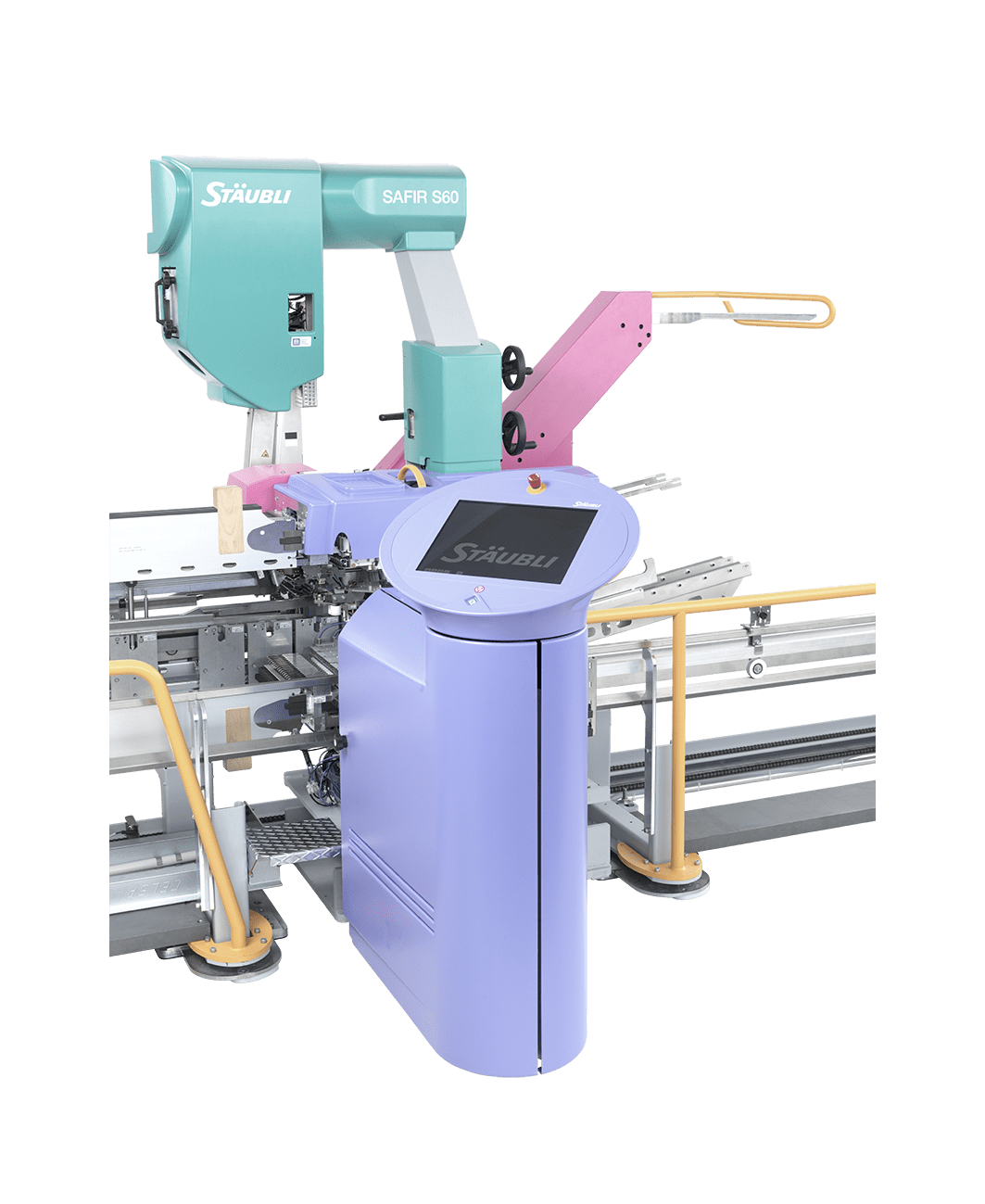

Creating machines that support the weaving of fabrics that are essential to global innovation motivates and inspires our teams. Flexibility and support are prerequisites for weaving technical fabrics, especially with new materials and 3D forms. Partnering with customers and our many decades of experience in R&D enable us to constantly advance our shed-formation solutions for frame and Jacquard weaving and our systems for weaving preparation, like the SAFIR automatic drawing-in machines. With our carpet and technical textile weaving systems, we provide the utmost flexibility. For instance, one of our technical weaving systems is in use at a university with a global reputation for excellence in research in new materials and developing new applications for the future. Stäubli is committed to providing flexibility and support not only here but also with customers around the world.

TF30 weaving system – a new solution for 3D weaving

Stäubli is presenting the new TF30 weaving system at Techtextil. This new Stäubli solution boasts innovative, discrete, and obvious benefits. The TF30 can enable weaving mills to meet the very specific and demanding requirements of the aerospace, medical technology, marine, or automotive industries – and thus enter new markets.

With a variable height of rapier weft insertion, this machine provides never-before-seen flexibility in shed programming and thus in weave structure. The weft insertion concept is designed to ensure gentle yarn treatment, thus the system can handle carbon and aramid yarns as well as ultra-sensitive ceramic yarns. Learn more about the TF30 and other Stäubli solutions for innovation in textiles at Techtextil.

Airbags, lightweight carpets, and filters for cheese or paper production have one thing in common

These and many more technical fabric applications are woven with the support of a Stäubli machine. Heavy dobbies for very large frame weaving machines are renowned for their robustness and resilience when vibration must be withstood. LXL PRO Jacquard machines provide all the necessary features for one-piece woven (OPW) applications, including top-quality airbags in any format. Featuring the NOEMI electronics architecture this Jacquard machine ensures a ontinuous Jacquard weaving process at the highest speeds and supports energy savings. Lightweight carpets for the transportation sector require weaves with very low loops. The Stäubli ALPHA 500 LEANTEC weaving system provides ingenious features for extremely uniform and precise loop production.

With a broad range of solutions for producing technical fabrics, Stäubli answers the needs of the weaving industry, from flat to 3D weaving.

About Stäubli

Stäubli is a global industrial and mechatronic solution provider with four dedicated Divisions – Electrical Connectors, Fluid Connectors, Robotics, and Textile – serving customers in many industrial sectors who aim to increase their productivity. Stäubli currently operates business units in 28 countries. Its global workforce of 6,000 shares is a commitment to partnering with customers in nearly every industry and to provide comprehensive solutions with long-term support. Originally founded in 1892 as a small workshop in Horgen/Zurich, Switzerland, today Stäubli is an international Group headquartered in Pfäffikon, Switzerland.