The continuing development of James Heal textile testing equipment is a result of the increased demand for more sophisticated protective clothing worldwide, particularly for the military and emergency services sectors. To make sure the fabric characteristics in specialised clothing serve their intended purpose, which is frequently essential to the wearer’s survival, accurate and trustworthy testing is required.

The James Heal team identified a change in consumer behaviour with trends towards “athleisure” wear and more advanced attributes becoming standard features of everyday clothing, and they first launched their Performance Testing Range. Four years after its debut at ITMA 2019, the James Heal Performance Testing Range has continued to grow, resulting in a collection of tools that collectively cover a wide range of performance wear.

range’s further developmenthas been made to add new performance testing elements to take into account what they viewed as a growing market for technical textiles in protective wear, particularly for first responder and military gear that has extremely specific testing issues.

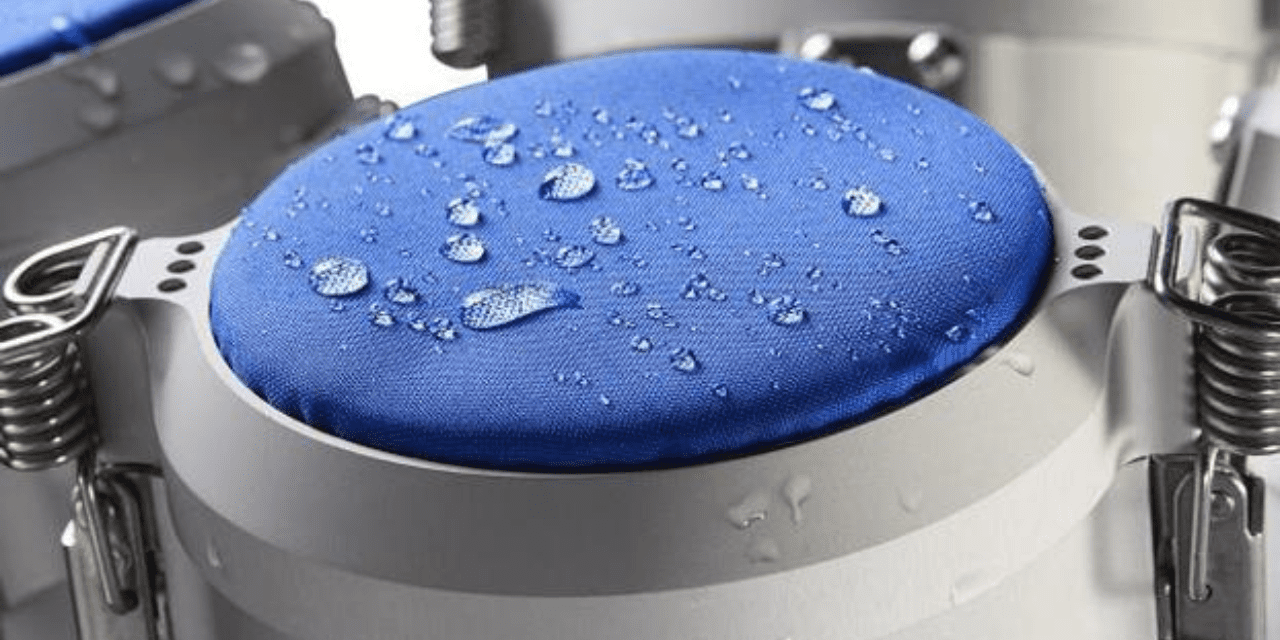

Each of the six performance testing devices in the line has distinctive, sometimes ground-breaking features of its own. In particular, AquAbrasion, which tests the impacts of wet abrasion to better mimic actual wear scenarios, and WickView, which has advanced above the current test standard for moisture wicking behaviour in fabric. James Heal has created their own test procedures and is working with the industry to set new benchmarks in these cutting-edge areas of textile testing. The TruRain sustained water repellency is another feature. In order to decrease waste and running expenses, tester recycles water, reducing waste by 99%. The range is completed with test instruments for hydrostatic head, air permeability, and drying rate.The Lab Manager’s Guide to Performance Testing, a free whitepaper by James Heal, has been made available to the industry to help with this specialised area of textile testing.

The more conventional textiles testing tools, such as those for flammability, abrasion, tensile strength, and tear resistance, run parallel to this innovation and complete James Heal’s line up. Together, these tools are widely used across the protective wear sectors for numerous applications to test for safety, durability, as well as wearer comfort.

PPE textiles and clothing are essential for protecting first responders and emergency personnel, according to Colin Whittaker, Business Development Manager at James Heal. military people in potentially dangerous situations. They must have particular functional qualities including water resistance, breathability, thermal protection, and flame resistance. To make sure they adhere to the requirements for safety and effectiveness, they must also be put through testing. These fabrics and clothing are made using intricate procedures that frequently combine a variety of fibres to provide the desired features. Our selection of test devices can meet these intricate needs and will keep evolving as textile technology continues to grow.

James Heal, which was founded in Halifax, West Yorkshire, in 1872, designs and produces textile testing equipment that is used all over the world. In 2014, the company joined the larger PPT Group, which has a variety of sister brands that each focus on testing numerousaspects of materials and products.