D.K.T.E. Society’s

TEXTILE AND ENGINEERING INSTITUTE, ICHALKARANJI.

- History of DKTE :

DKTE Society’s Textile and Engineering Institute enjoys a unique position in the field of Professional Education and in the Textile Industry of India. Apart from catering to high standard of education in the field of Engineering and Textiles, the Institute is deeply involved in providing various kinds of services to the Textile and other industries not only in and around Ichalkaranji but also all over the country in the form of consultancy, training, testing facilities, research and development etc.

DKTE Society’s Textile and Engineering Institute is taken as the best Institute in country especially in the field textiles. This institute also has made its mark at international level. Many Universities and industries from abroad have signed MoU’s for cooperation with DKTE. DKTE is working on many Government as well as Non-Government sponsored prestigious projects. Recently Ministry of Textiles, Govt. of India has selected DKTE for their most prestigious project “Centre of Excellence” in Nonwovens. Students of DKTE are holding senior positions in Indian Textile Industry and also are have their presence in many countries such as USA, Europe, Asian and African countries.

Ichalkaranji is a reknowned centre for decentralized Textile Industry. Traditionally Ichalkaranji is known for powerlooms and products like Dhoti, Malmal, Cambric etc.

During last 10 years this centre has been modernizing into automatic and shuttleless looms. Over 8000 shuttleless looms have been installed in and around this town and Ichalkaranji has been recognized as the fastest growing shuttleless weaving centre of the entire country. DKTE has stimulated this growth by organizing many seminars, conferences and training programs for the loom owners and weavers.

Along with the Ichalkaranji Municipal Council, DKTE has established a Kranti Mahila Garment Training Centre where women are trained, free of cost in garment – cutting, stitching, embroidery and finishing. In last four years around 5000 women coming from poor and from BPL category have been trained at this centre. As a result in recent past there has been an emergence of garment manufacturing industry in this region and over 6000 stitching machines have been installed in this new industry. With the advent of these changes, Ichalkaranji is now known not only as a modern weaving centre but also as a garment centre.

Due to the existence of DKTE which caters to the need of technically qualified manpower, many big Textile companies have started their textile projects near Kolhapur. Many of these projects are in collaborations with industries abroad. Kolhapur District is now being recognized as a major Textile Hub of the country. Thus DKTE has played a pivotal role and acted as a catalyst in this development of textile industry in this region.

The industrial development brings with it economic development of the region and hence the people. The per capita income in Ichalkaranji, compared to any town below the population of 5 lakh, is the highest in the country.

- Salient Futures of the Institute:

- Our institute is the first Engineering college to be started in Maharashtra State (1982), on a no grant basis.

- Eligible Prorammes have been accredited by National Board of Accreditation (NBA).

- ISO 9001:2008 Certified Institute, Awarded ‘A’ Grade by Technical Committee, Govt. of Maharashtra.

- 100% placement for Textile students & >85% for Engineering students.

- Central Government has sanctioned Rs. 00 Lakhs under ‘Centre of Excellence’ in Nonwovens.

- Due to very strong interaction with the industry, our institute received Textile Machinery worth Rs. 00 Lakhs, free of cost from leading machinery manufacturers from Germany, Switzerland, Italy & Hong Kong, Spain, and Japan.

- Our Institute is one of the few Engineering Institutes from India, to be selected under TEQIP (Technical Education Quality Improvement Programme) for funding from World Bank, for up gradation of Technical Education.

- Institute received grant of Rs. 00 Lakhs under Textile Development Cluster Scheme for development of R&D Centre in Textiles.

- Institute has been sanctioned a project worth of Rs. 08 Lakhs from ‘Technology Information Forecasting Assessment Council (TIFAC), Department of Science & Technology (Mission REACH) for establishment of nodal centre for Technical Textiles at our Institute. This nodal centre has been established to achieve academic excellence in textile education & to develop into internationally recognized centre for designing & development of high value added textiles and associated services to industry and Society.

- Department of Science & Technology has granted us permission to establish Technology Business Incubation in Textiles at our Institute. The total cost of project is Rs. 00 Lakhs.

- Secured 34th All India ranking & 2nd rank in Maharashtra in the Survey of Engineering colleges carried out by Competition Success Review – GHRDC in 2009.

- Secured 51st All India ranking & 5th rank in Maharashtra in the survey of Engineering Colleges carried out by Competition Success Review – GHRDC in

- Secured 40th All India ranking & 4th rank in Maharashtra in the survey of Engineering Colleges carried out by Electronics For You in 2010.

- Secured 14th All India ranking and 4th in Maharashtra State in survey of Engineering Colleges carried out by Competition Success Review – GHRDC in

- Ranked 5th in Maharashtra State & 8th in Western India through the Survey conducted by CSR – GHRDC Engineering Colleges Survey 2012 for Top Promising Engineering Colleges of Excellence. The survey was based on Infrastructure (Physical & Academic), Faculty Research, Consultancy, EDP & other Programs, Admission and Competency Building, Placement / Industry Interface. CSR-GHRDC, New Delhi is well known for Management & Research in academics. In last 4 Years, our Institute has consistently secured rank in this survey conducted by CSR-GHRDC.

- Our Institute is graded AA+ by Career 360 Magazine and ranked 5th in Maharashtra. The grading was based on Survey throughout India considering Eligibility, Scope for Research, Use of New Technology etc.

- Collaborations with leading foreign Universities like Eastern Michigan University(USA), North Corolina State University (USA), Troy University (USA), DeVry University (USA), Kenyatta University (Kenya), University of California Los Angeles (USA), Copperbelt University (Zambia), Busitema University (Uganda), The School of Technology (Indonesia).

- Our Faculty have published over 600 papers in various National & International Journals of repute.

- Apart from academics, our Institute has been offering various services to industry which includes Product development, Turnkey Consultancy, Project report preparation, Process modification, Effluent Treatment, Energy Conservation, Testing, organization of Seminars, Conferences, Workshops & Customized Training programmes.

- MoUs with International Machinery Manufacturers for Training, R & D.

- Highly experienced and dedicated faculty.

- Eminent visiting faculty from industry, research organizations and academia.

- Low student to faculty ratio for better students teacher interaction.

- 24*7 high speed internet and Wi-fi & Video Conferencing facility.

- Ichalkaranji Information :

- The Decentralised Powerloom Industry Ichalkaranji started growing at a very rapid rate around 1980. The industries like spinning mills, chemical processing units, warping and sizing units, which support the powerloom industry also started growing in numbers. The developing industry, requires technical qualified manpower. At that time there was only one Institute in the entire Maharashtra at Mumbai which catered to the education programmes in Textiles. The students passing out from this institute were not willing to come to a rural and mofusil area like Ichalkaranji.Nine co-operative organizations from Ichalkaranji therefore, came together under the leadership of Mr.K.B. Awade to form an Education Society and this Society was named after Shri Dattajirao Kadam, a veteran leader and an ardent co-operator and who was mainly instrumental in the development of Textile Industry at Ichalkaranji. Thus the Dattajirao Kadam Technical Education Society popularly known as DKTE came in to existence. The DKTE society appealed to the State Govt. to permit them start the Diploma course in Textiles and the State Govt. accorded their approval in August-1982 on the condition that the Institute will not receive any grant in aid from the Govt. and will have to work on self supporting basis. The D.K.T.E. Society accepted this challenge and started the Textile and Engineering Institute with a Diploma course in Textiles on 26th September, 1982. This institute is one of the first Institute to be started on no grant basis in the State of Maharashtra. Observing the performance of this Institute Govt. of Maharashtra resolved the policy of permitting professional college to be started on no grant basis in the State of Maharashtra.Textile and Engineering Institute began its activities by introducing a Diploma Course in Textile Manufactures (DTM) in the academic year 1982-83. In the year 1983-84 two degree courses were introduced and in the course of time diploma, degree, post-graduate and Ph.D. level pogrammes were added.

As DKTE has been promoted by nine cooperative organizations, majority of which are industries, the culture of industry – institute interaction was established right from the inception.

- PROGRAMMES CONDUCTED :

The Textile and Engineering Institute caters to three diploma programmes in the area of Textiles, ten degree programmes, five programmes in textiles (five in different branches of engineering), five post graduate programmes (three in textiles and two in engineering) and a Ph.D. facility in textiles

- The detailed list of programmes conducted at the institute is given below:

Name of the Course Accreditation Status

Year of Starting Intake Capacity Duration (Yrs.)

DIPLOMA COURSES Diploma in Textile Manufactures Accredited 1982 60 03 Diploma in Textile Technology — 1995 30 03 Diploma in Fashion Technology — 2008 30 03 DEGREE COURSES — B.Text. Textile Technology Accredited 1983 60 04 B.Text. Man-Made Textile Technology Accredited 1983 30 04 B.Text. Textile Plant Engineering Accredited 1984 30 04 B.Text. Textile Chemistry Accredited 1987 60 04 B.Text. Fashion Technology — 2006 30 04 B.E. Electronics Engineering Accredited 1989 120 04 B.E. Mechanical Engineering Accredited 1992 120 04 B.E. Computer Science and Engineering Accredited 1999 60 04 B.E. Information Technology — 2001 60 04 B.E. Electronics & Telecommunication Engineering Accredited 2002 60 04 POST-GRADUATE COURSES — M.Text. Textile Technology Accredited 1997 18 02 M.Text.Textile Chemistry — 2006 18 02 M.Text.Technical Textiles — 2009 18 02 M.E. Electronics Engineering — 2010 18 02 M.E. Mechanical Engg. (Product Design & Development) — 2010 18 02 M.B.A.(Master of Business Administration) — 2008 60 02 M.B.A. (Master of Business Administration – Textile) — 2009 60 02 DOCTORATE — Ph.D. – Textile Engineering — 2002 24 — - Students Corner

EXAMINATION RESULTS

Percentage of passing

Sr. No. Course Year 2008 – 09 2009-10 2010-11 1 B.Text.Textile Technology 87.50 83.58 98.48 2 B.Text.Man-Made Textile Tech. 96.30 85.19 91.67 3 B.Text.Textile Plant Engineering 100.00 92.86 100.00 4 B.Text.Textile Chemistry 100.00 97.10 96.61 5 B.Text.Fashion Technology — 100.00 100.00 6 B.E.Electronics Engineering 88.00 78.13 87.64 7 B.E.Mechanical Engineering 92.50 97.01 88.41 8 B.E.Computer Science & Engineering 93.85 78.13 96.70 9 B.E. Information Technology 93.33 96.97 95.95 10 B.E.Electronics & Tele-Comm. 85.71 94.20 92.11 - Ranker students in University Examination held in 2008-09, 2009-10 & 2010-11 are as under :

Year 2008-09 2009-10 2010-11 31 34 32 - GATE qualified students for the academic year 2008-09, 2009-10 & 2010-11

Year 2008-09 2009-10 2010-11 13 13 22 240 and more students of our institute have won Prizes, awards at National level paper / project presentation contest for last 3 years.

- PLACEMENT

Sr.No. Courses Percentage of Placement 2008-09 2009-10 2010-11 1 B.Text. Textile Technology 100 100 100 2 B.Text. Man-Made Textile Technology 100 100 100 3 B.Text. Textile Plant Engineering 100 100 100 4 B.Text. Textile Chemistry 100 100 100 5 B.Text.Fashion Technology 100 100 100 6 Electronics Engineering 82 88 91 7 Mechanical Engineering 89 85 92 8 Computer Science & Engineering 70 79 88 9 Information Technology 68 73 82 10 Electronics & Telecommunication 67 71 83 Total no. of companies recruiting our students

Textile – 87

Engineering – 55

Campus Placement

For, Textiles in last 25 years placement has been always 100%. The major recruiters for Textile area.

- RIETER

- MARZOLI

- CLARIANT

- HUNTSMAN

- SAURER

- MURATA

- SCHLAFHORST

- USTER

- Arvind Mills

- Vardhman Spg. & Gen. Mills

- Reid & Taylor

- ATE Marketing Ltd., Mumbai

- Siyarams

- Raymonds Ltd

- Mandhana Bornemaun, Banglore.

- Maral Overseas

- Nagreeka Exports Ltd

- Santogen Exports Ltd Mumbai

- Mandhana Dyeing

- Donears

- Indo Count Industries

- Saurer, Mumbai

- Bombay Dyeing

- Shahi Exports

- Alok Industries

- Smith

- Ashima Ltd., Ahmedabad

- HCL, Pune

- Welspun

- Croda Chemicals Ltd.

- CLC Group

- H.C.L

- Nagreeka Exports

- Vardhaman Polytex

- Morarjee Brembana, Nagpur

- Century Enka (KSF)

For other Engineering courses like placement is in the recruit of 70-85%. The major recruiters for other Engineering disciplines are:

Ø TCS Ø L & T Infotech,

Ø Kirloskar Brothers

Ø Infosys

Ø Accenture

Ø Aloha, Pune Ø Aplab Ø Bharat Forge Ø Force Motors Ø Indian Navy Ø Congniznat Ø Wipro

Ø Mahindra Tractors

Ø Pari Robotics

Ø Patni Ø Qual Soft Pune Ø Satyam Ø Syntel Ø Technimont ICB Ø Unisoft Ø HCL Ø Ghatage

Ø Auto. Ltd.

Ø Tech Mahindra Ø Tata TAL Ø Bosch Ø Petro Chemicals Ø KPT Ø Aryans Infosys CAREER OPPORTUNITIES

- ONGOING SPONSORED PROJECTS:-

| Sr. No. | Name of the Projects | Sponsoring Agency | Sanctioned / Amount (Rs.in Lakhs) |

| 1 | Centre of Excellence in Nonwovens | Government of India, Ministry of Textiles | 2500.00 |

| 2 | Entrepreneurship Development Cell | AICTE, New Delhi | 7.50 |

| 3 | Industry Institute Partnership Cell (IIPC) | AICTE, New Delhi

| 10.00 |

| 4 | Technology based Entrepreneurship Programme | DST New Delhi & EDI, Ahmedabad | 2.65 |

| 5 | MODROB (for PCB Software) | AICTE, New Delhi

| 4.50 |

| 6 | National Conference on Recent Trends in Electronics and Tele- Communication Engg | AICTE, New Delhi | 1.00 |

| 7 | National Conference in Electronics and Communication Engg | DRDO, New Delhi | 0.40 |

| 8 | Robotics Research Lab | MHRD, New Delhi & IIT, Bombay | 0.60 |

| 9 | Faculty Development Porgramme | AICTE, New Delhi | 10.09 |

| 10 | Faculty Development Programme / /EAC | EDI & DST, New Delhi | 1.75 |

| 11 | DKTE Technology Business Incubation (TBI) | Department of Science & Technology, Govt. of India | 4.84 |

| 12 | Ministry of Micro, Small & Medium Enterprises (MSME) | Ministry of Micro, Small & Medium Enterprises, Govt. of India | 62.50 |

| Sr. No. | Name of the Projects | Sponsoring Agency | Sanctioned / Amount (Rs.in Lakhs) |

| 13 | Mesta fibres – to study properties and application in Eco Textiles | University of Agricultural Science, Dharwad | 0.25 |

| 14 | Study of quality parameters of dark brown natural coloured-cotton genotype | University of Agricultural Science, Dharwad | 0.25 |

| 15 | Technology Information, Forecasting & Assessment Council (TIFAC) | Department of Science & Technology, Govt. of India | 507.08 |

| 16 | Science & Engineering Research Council | Department of Science & Technology, Govt. of India | 14.20 |

| 17 | Testing of Nonwovens | Department of Science & Technology, Govt. of India | 8.0 |

| 18 | Technological Based Entrepreneurship Development & Programme | EDI & Department of Science & Technology, Govt. of India | 2.00 |

| 19 | Industrial Product Design Center under Nationally Coordinated project (NCP) Scheme | AICTE, New Delhi | 22.50 |

GOVERNMENT SPONSORED PROJECTS :

Considering the reputation and the capability of the Institute, the Govt. of India has selected this Institute for many prestigious projects. The list of the project is given below.

- Centre of Excellence In Nonwovens (COE)

The objective of creation of Centre of Excellence is to provide infrastructure at one place for the convenience of the manufacturers of technical textiles in India.

The Centre of Excellence in Nonwovens will consistently pursue to improve its technical basis for the development of innovative nonwoven products which results in new application and value addition. The Centre of Excellence in Nonwovens at DKTE offers technical equipments to accomplish increasing complex research tasks, know-how and technical excellence of qualified personnel.

Activities of COE

- Research and Development

- Training

- Testing

- Consultancy

- Technology Business Incubation

- Rapid Prototyping

- Library and Information Centre

- Exhibition and Display Centre

- TIFAC-CORE Department of Science and Technology (DST) / Technology Information Forecasting and Assessment Council (TIFAC) have granted permission to create TIFAC-CORE in Technical Textile at our Institute. Theproject will be of Rs.500.00 lakhs, funded by DST and Industry for establishing the laboratories and forging linkages with other academic, research & industry as well as other COREs. This will help in establishing Nodal Centre in Technical Textiles at our Institute. The laboratories are equipped with Technical Textile related machinery like Coating/Laminating machine, Warp Knitting machine, Weaving machines, Testing machines like Instron, Thermal Conductivity tester, F R testing, Air-Permeability tester, Bursting strength tester,etc.

- Technology Business Incubator (TBI) A Technology business incubator nurtures the development of technology based and knowledge driven companies helping them to survive and grow during the start up period (2-3 years) by providing an integrated package of work space, shared office services, access to specialized equipment and value added services like management assistance, business planning, access to finance, technical assistance and networking support. The main objective of the TBI is to produce successful business ventures that create jobs and wealth in their region.

Trust Area: Textile & Garment Technology

Project Cost: 484.31 lakhs

Sponsored by: Department of science and technology, New Delhi

- Entrepreneurship Development Cell (EDC)

Institute has established “”Entrepreneurship Development Cell” (EDC), which has been sponsored by Department of Science & Technology Govt. of India, New Delhi.

Objectives of EDC :

To act as an institutional mechanism for providing various services including information to budding S&T entrepreneurs.

To create Entrepreneurial culture in the parent institution and other

To catalyze and promote development of S&T based enterprises and promote employment opportunities.

To respond effectively to the emerging challenges and opportunities both at national and international level relating to SMEs and micro enterprises.

- Development of an Instrument for Identification of Handloom Woven Fabrics

In India textile industry is divided in three main sectors: hand loom sector, decentralized sector, and the organized sector.

Handloom industry employs large population in manufacturing the fabrics of various types. As such government of India protects the handloom industry. The industry is protected to save the employment of lakhs of people engaged in this industry.

The protection is in the form of reserving few fabric qualities and the subsidy, which power loom owners are not entitled to. Moreover, there are exports of large quantities handloom fabrics as there is good demand for the Indian handloom fabrics due to the texture and designs etc.

The possibility of power loom owners manufacturing the fabric on power loom and selling it as hand loom fabric in domestic and international market can not be completely overlooked. The related authorities receive complaints regarding such cases.

Till recent days, there was no instrument to differentiate the fabric made on handlooms and other power operated looms. As such it becomes very difficult to solve such complaints.

Now, we have made an instrument as shown in photograph to identify handloom fabrics beyond doubt. The institute is patenting the same.

- Industry Institute Partnership Cell (IIPC)

The institute has come up with an Industry-Institute Partnership Cell (IIPC) sanctioned by the All India Council for Technical Education (AICTE) to act as an interface between the Industries and Institute for collaborative activities.

To strengthen the bonds between industry and institute the cell is carrying out following activities.

- Arranging industrial training for students.

- Interacting with R&D Organizations for conducting joint research work

- Arranging technical festivals/open houses/student design competitions, personality development workshops

- Arranging short-term programmes : Duration of 5 to 7 days for the benefit of Professionals in various technical disciplines

- In house training programme at the request of industries at their location

- Development Of Needlepunched Nonwoven Fabric Products From Banana Fibre

Produce needlepunched nonwovens from banana fibres using existing Banana fibre extractors

Test the needlepunched nonwovens for their physical and mechanical properties so as to find out samples with properties that compare favourably with commercially standard samples of polyester and polypropylene fibres.

To start with nonwovens of polyester and polypropylene which would be taken for study in present project would be interlinings in garments, geotextiles and filtration fabrics. Thereafter based on observed properties of tested nonwovens of banana fibre more substitutes of polyester and polypropylene nonwovens would be considered.

Study the chemical bonding process and biodegradation of banana fibres.

Detailed study of existing banana fibre extractor would be made to explore possibilities making improvements in design.

- Micro, Small & Medium Entreprises (MSME)

Ministry of MSME (Micro, Small & Medium Enterprise), Govt. of India has approved our Institute as “Incubate” to extend the support of SMEs for entrepreneurial and managerial skill development. Ten new innovative ideas have been selected under this scheme. They will receive the funds shortly.

- INDUSTRY INTERACTION :

- Training Programmes for Industry Personnel

| Name of Industry / Organization | Training Area | Beneficiaries | No. of participants |

| Kolhapur Institute of Technology Kolhapur | Industry Institute Interaction | Faculty Members | 20 |

| Spinning Mills | Spinning Technology | Mill Supervisors | 15 |

| Shetkari Sah. Soot Girani Ltd., Sangole | Maintenance Management | Supervisors | 60 |

| Mata- Balak Utkarsha Pratishtan, Sangole, | training programme of woollen sitting mat | Technicians | 3 |

| Local Textile Industry | Training programme on “Tie & Dye Technology | Entrepreneurs | 4 |

| Engineering Colleges | Faculty Development programme on Entrepreneurship Development | Faculty of other Engineering Colleges | 22 |

| Kranti Agrani G.D.Bapu Lad Mahavidyalaya,Kundal | Entrepreneurship Awareness Camp | Managements Students | 94 |

| Local Textile Industry | Technology Based Entrepreneurship Development Programme (TEDP) | Entrepreneurs | 23 |

| Local Textile Industry | Awareness meet on Technical Textiles – Prospects and Future Trends | Entrepreneurs | 147 |

2. Consultancy Services Rendered

| Sr. No. | Name of Company | Area of Consultancy |

| 1 | Kolhapur Muncipal Corporation | Environmental Status Report |

| 2 | Ichalkaranji Municipal Council | Design of Common Effluent Treatment Plant |

| 3 | Laxmi Co- op. Industrial Estate, Ichalkaranji | Design of Common Effluent Treatment Plant |

| 4 | Ichalkaranji Muncipal Council | Preparation of Environmental status report |

| 5 | Savio India Ltd, Coimbatore | TFO survey across various regions in India |

| 6 | Ajara Co.op. Spinning Mills, Ajara | Spinning |

| 7 | Trimurti Paithani Centre,Paithan. | Weaving Machine Development |

| 8 | Nirmal Sanitary Napkins, Jeur, Solapur | Meditech |

| 9 | Raymond Zambaiti, Kagal | Weaving & Processing |

| 10 | University of Agricultural Science, Dharwad | Natural Mesta Fibre |

| 11 | University of Agricultural Science, Dharwad | Coloured Cotton |

| 12 | Mata, Balak, Utkarsh Manch, Sangola | Wool Fibre Product Development |

| 13 | Unique auto Assemblies Pvt. Ltd. Ichalkaranji. | Feeding system design and optimization of Rocker Arm Support no. 510 and 610 |

| 14 | Parvati Foundry, Ichalkaranji. | Feeding system design and optimization of Vista Body |

| 15 | Parvati Foundry | Design and simulation of gating system. |

| 16 | Jagadeesh Iron & steels Pvt Ltd. Miraj M I D C, | Design and simulation of gating system of Carraro planetory carrier |

| 17 | Unique auto Assemblies Pvt. Ltd. Ichalkaranji. | To estimate model behavior of damping pulleys |

| 18 | KPT, Shirol | Development test Rigs |

As the Textile and Engineering Institute has been promoted by a group of industries for the purpose of supporting them in the supply of qualified and skilled man power as well as in other areas, the culture of the institute industry interaction existed right from the inception. Today this institute is take as a role model for interaction with industry. The institute supports the industry in various areas. The institute has been involved in interaction with industries not only from India but with industries abroad also.

The broad areas in which the institute provides support to the industry are:

- Training at different levels in all areas of textile industry.

- Testing facilities from fibres to finished fabric including nonwovens and technical textiles.

- Product / Process development.

- Project report preparation / Project appraisals.

- Turnkey projects. The major activities in the area of industry interaction are as follows :

- Training : Institute has completed 300 training programmes during last 10 years for personal from various industries at different levels.

The training facilities are extended for industries and educational institute from overseas also.

- Testing Facilities : Over 10,000 test reports have been given during last 10 years in the areas of fibres, yarns, fabrics and garments.

- Product / Process Development : Institute has been helping the industry in the development of production and process. Following is a brief list of major product and process development activities successfully completed by the Institute.

- Philips (India), Pune : Development of Spider Cloth

- Modi Hoover (India) Ltd., Pune : Development of Filter Fabric

- Gogte Textiles, Belgaum : Development of Electronic Pile

Control System for Terry Loom

- K. Synthetics, Kota : Devep. of Acrylic Fibre Fabrics

- Pashupati Acrylon, Delhi : Development of Terry Towel by

using High Moisture Absorbent

Acrylic Fibre

- Hitkari Fibres, Mahad, Dist.Raigad : Development of Cotton Scrim Cloth

- Deccan Embroidry, Pune : Development of a Fabric equivalent

to Swiss cotton from Indigenous

cotton

- Tetra Pack, Pune : Development of tubular fabric for

conveyor belt

- Sunrays Industries Ltd., Pune : Development of Bolting Fabric

- Grasim Industries Ltd., Mumbai : Processing of Jute / Viscose Blend

- Siam Synthetics, Pvt. Ltd., Thailand : Cost Reduction

- Nirmitee Engineers, Pune : Industrial Fabric Development

- Padmaja Bleachers, Pune : Product Development

- Project Report Preparation and Appraisal : The Institute is recognized by the State Govt. of Maharashtra, M.S.C. Bank, NCDC, IDBI, State Bank as well as many other financial institutes for preparing the techno-economic feasibility reports as well as for appraisal of projects. The Institute has prepared 150 project reports and has completed project 225 appraisals during last 10 years.

- Turnkey Projects : The Institute provides consultancy for turnkey implementation of projects in the areas of spinning, weaving, chemical processing and garment making 25 turnkey projects have been completed uptil now.

- A brief list of major projects completed under turnkey consultancy is given below :

| Sr. No. | Name | Investment (Rs.in Crores) |

| Spinning | ||

| 1 | Indira Gandhi Mahila Sahakari Soot Girani Ltd., Ichalkaranji | 62.00 |

| 2 | Mahatma Phule Co-op. Spinning Mills, Vadgaon | 54.00 |

| 3 | Shirol Magaswargiya Co-op. Spg. Mills, Shirol | 56.00 |

| 4 | Rajarambapu Co-op. Spg. Mills, Islampur | 58.00 |

| 5 | Yashwantrao Chavan Co-op. Spg. Mills, Tung | 55.00 |

| 6 | Babasaheb Deshmukh Co-op. Spg. Mills, Atpadi | 55.00 |

| 7 | Swami Ramanand Bharati Co-op. Spg. Mills, Tasgaon | 54.00 |

| 8 | Shirala Co-op. Spg. Mills, Battis Shirala | 56.00 |

| Weaving | ||

| 1 | Global Textiles Ltd., Ichalkaranji | 3.85 |

| 2 | Chaya Textiles Ltd., Ichalkaranji | 3.85 |

| 3 | Jayant Textiles Ltd. Islampur | 3.85 |

| 4 | R.M. Mohite Textiles Ltd., Vadgoan | |

| Processing | ||

| 1 | Karnataka Processors, Borgaon, Dist. Belgaum | 10.00 |

| Garment | ||

| 1 | Tube Knits Fashion Ltd.,Tirupur | |

| 2 | Indraprastha Co-op. Knitting Industries, Islampur | 3.45 |

c) Research and Development : Generation and dissipation of knowledge especially for the benefit of the industry and society is an important function of any professional educational Institute. K.T.E. Society’s Textile and Engineering Institute has always been on the forefront in this area. The faculty members of this Institute are deeply engaged in carrying out research sponsored by industry as well as in in-house research. As a result of this as many as 1100 research papers have been published / presented by the faculty members in reputed national and international journals as well as in important national and international conferences. As a result of this research and development activities, five patents have been filed by the faculty of this institute.

7) QUALITY EDUCATION:

D.K.T.E. Society provide for the Textile and Engineering Institute a ultra modern and world class infrastructural facilities in the form of specious buildings, equipped with excellent amenities and laboratories and workshops with machines and equipments with latest technologies.

The facilities in the laboratories of Textile Department are unparallel not only in India but probably anywhere in the world.

A glimpse of the equipment and machinery available in various textile laboratories is given below:

Workshop / Laboratories

- Spinning Workshop

- Spinning Maintenance Laboratory

- Weaving Workshop

- Textile Physics & Testing Laboratory

- Man-Made Textile Laboratory

- Garment Manufacturing Laboratory

- Dye House

- Chemical Testing Laboratory

- Textile Computer Laboratory

- Textile Electronics Laboratory

- Technical Textiles Laboratory

Major Equipments / Machineries

Spinning Workshop

- Rieter Comfor Compact Spinning K-40

- Rieter Comber E-70 R

- Rieter Autoleveller Draw Frame RSB-D30

- Murata Air Jet Spinning MJS 802

- Schlafhorst Autocoro 288

- Trumac / Trutzschler Blow Room Line

- Trumac DK-780 Card

- KTTM Ring frame RXI 240 E

- LMW Speed Frame LF 1400

- Pinter Fani Core Spun Lycra Attachment

- LMW Ring Frame LG 5/1

- Paess Parallel / Soft Winding Machine

- Vijay Lakshmi Two For One Twister

- Fancy Twister

- Ring Doubler Amsler Fancy Yarn Attachment

- Xorella Yarn Conditioning

- Zinser Ringframe 351 C

- Savio TFO

- SSM Winder

Spinning Maintenance Laboratory

- Flat End Milling Machine

- Flat Clamping Machine

- Flat Grinding Machine

- Roller Mounting Machine

- Cots Grinding Machine

- Cot Checking Instrument

- Cot Calendaring Machine

- Top Roller Greasing Machine

- Arbour Flushing / Cleaning Machine

Weaving Workshop

- Dornier Rapier Machine

- Sulzer Projectile Weaving Machine with Training Modules

- Bonas Electronic Jacquard

- Smit Rapier Weaving Machine

- Somet Air Jet Weaving Machine

- Smit Air jet Weaving Machine

- Mayer & Cie Knitting Machine

- Savio Polar Winding Machine

- CCI Tech.sample Sizing Sample Warping

- & Sample Loom Set-up

- Pailung Interlock Knitting Machine

- Liba Sample Warp Knitting Machine

- Muller Needle Loom

- Braiding Machine

- Harish Vivita Air Jet Weaving Machine

- Ruti C Weaving Machine

- Cimmco Auto Loom

- Design Studio (Wonderweaves & Textronics)

- All Types of Conventional Shuttle Looms & Preparatory Machines

Textile Physics & Testing Laboratory

- USTER AFIS PRO

- Instron Universal Testing Machine (5565)

- Zweigle Yarn Abrasion Tester

- High Volume Instruments HFT (Premier)

- Premier aQuara NL

- Premier Tensomax 7000

- Yarn Evenness Tester (Premier –IQ)

- MESDAN Tester (STRETECH 50 M)

- Tensolab Tensile Testing Machine

- Cotton Trash Analyzer

- Uster CSP Tester

- Classimat

- Handloom Fabric Identification System

- Microscopes

Carl Zeiss Stemi DVG Stero Zoom Microscope

Carl Zeiss Tringwller Stero Zoom Microscope

Carl Zeiss Meterized Stero Zoom Microscope

Carl Zeiss Image Analysis System

Man-Made Textile Laboratory

- Air Texturising

- Draw Texturing

- Pilot Melt Spinning Machine for PET, PP, Polyamide Fibres

- Two Stage Filament Yarn Drawing Machine

- High Speed Draw Winder

- Dyanfil M

- Crape TFO

- Air Covering Machine

- Density Gradient Column

- Melt Flow Index Tester

Dye House & Chemical Testing Laboratory

- THEN AIRFLOW AFF50 Softflow Dyeing Machine (50 kg)

- Fong’s Soft Flow Dyeing Machine (10 kg)(All Fit-10)

- Morapex Extractor

- Mathis Labomat

- Tessile Computer Colour Matching Systems

- Premier Computer Colour Matching Systems

- Treepoint Computer Colour Matching Systems

- Chemico UV-Visible Spectrophotometer

- Infra Red Colour Dyeing Machine

- 2 kg Soft Flow Dyeing Machine

- 10 kg Soft Overflow Dyeing Machine

- Single Package Dyeing Machine

- Garment Dyeing Machine

- All Testing Equipments

- Effluent Characterization Laboratory

Garment Manufacturing Laboratory

- All Types of Basic & Special Stitching M/cs

- Bartack Machine

- Industrial Blind Stitch Machine

- Chain Stitch, Button Stitch Machine

- Button Hele Machine

- CAD (Textronics Design System)

- Reach CAD & Fashion Studio

- Wonderweaves Design Software

- Richpeace CAD Software

- Lectra CAD Software

- Pattern Making Lab

- Computeriszed Embroidery Machine

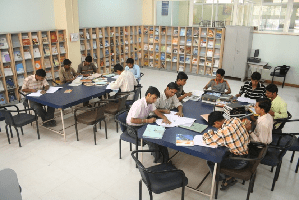

LIBRARY :

The institute has a spacious (Area 1200 sqm.), cosy & modern library, designed to meet the burning needs of the budding technocrats. Our library is a treasure house of many important books in the field of Textile Technology, Fibres, Man-Made Fibres Technology, Textile Chemistry, Mechanical Engineering, Electronics Engineering & Computer Science & Management. Several handbooks, encyclopedias and reference books are available in the library. The details of the library acquisitions are as follows.

Books : 49,948

Bound Journals : 3,727

Journals subscribed : 223

Per annum

Standards & Reports: 5,500

The library has also acquired more than 5,564 Video cassettes and C.D. on recent machinery & equipments, case studies, management etc. Separate Internet facility has been provided in the library to facilitate students to have access to the information. We have always been receiving books & journals as gifts from many well wishers and industries. A large number of readerships of library come from industry.

COMPUTER SECTION : More than 750 latest computers in the institute. All departments are connected with fiber optics. High speed 20 mbps internet facilities, campus wide structured network. Free Wi-Fi facility available for students. Three IBM – 226 x series, One NAS server with 2 TB CAP, One IBM AIX power series, One IBM P3 server.

MOU WITH INDUSTRY AND UNIVERSITIES : The image the Institute has created in the field of education, has attracted many Universities and Industries from India and overseas to enter into collaboration with DKTE.

A brief list of the Universities and Industries with whom the MoU has been signed is given below :

- Universities / Educational Institute

1) Eastern Michigan University, Ypsilanti, MICHIGAN 48197

2) North Carolina State University, Releigh, North Carolina, USA

3) Troy University, Albama 36082, USA

4) University of California Los Angeles Extension (UCLA)

5) Devry University, USA

6) Copperbelt University, Riverside Kitwe, Zambia

7) Busitema University, Uganda

8) Kenyatta University, Kenya

9] The School of Textile Technology, Indonesia

- Industrial Organisation

1) Aztecsoft Pune

2) Hoyt Engineering Solution Pvt.Ltd. Pune

3) Dogetech Industrial Co.Ltd., (Tung Hsla), Taiwan

4) The Indus Foundation, USA

5) Fong’s National Engg.Co.Ltd. Tsing YI, N.T., HONG KONG

6) Smit Textile, Italy

7) Indian Text. Acces. & M/C. Mfg.S’ Assn. Mumbai

8) ITEMA India Ltd. Gurgaon, Haryana

9) Bharat Forge Ltd., Pune

10) IBM rational seed programme, Bangalore

11) Infosys, Bangalore

12) Dyster India

13) Himmatsingka, Hasan, Karnatak

14) Ichalkaranji Garment Cluster Ltd. Ichalkaranji (SPV)

15) Dale Carnegie Training (India), DCTI Walchand People First Ltd.

16) Bosch Rexroth India Ltd. Gujarat

17) HANSA Embedded System Academy, Mumbai

18) PS Solutions, Pune

19) Cranes Software International Ltd. Bangalore

SOME SPECIAL ACHIEVEMENTS :

- Project preparing 5 km long Carpet and the Carpet Winding Machine for the Sultanate of Oman. Designing & Development of Carpet Laying & Winding Machine for the Ministry of Culture & National Heritage, Sultanate of Oman.

Development of Carpet Fabric for the Ministry of Culture & National Heritage, Sultanate of Oman.

- Preparation of project report for the Nigeria Government, for starting Diploma course in Textiles in Nigeria.

- Textile Institute in collaboration with the Busitema University in Uganda on the invitation of the Govt. of Uganda.

- Textile Institute in collaboration with the Copperbelt University in Zambia on the invitation of the Zambian Govt.

- Textile Encyclopedia in Marathi.

The State of Maharashtra has always been on the forefront as far as Textile Industry is concerned. It has a major share of industrial installation particularly in “Decentralised Textile Industry”. Most of the entrepreneurs and workers engaged in the decentralized sector do not have any formal education or training. As most of the technical literature available on textiles is in English and this is of not much use to these persons as many of them are not able to read or write English.

Knowledge is the key for sustenance and progress of any industry. Keeping this in view DKTE in collaboration with Rajya Marathi Vikas Sanstha of the Maharashtra State Govt. has undertaken an ominous task of translating the Textile Technology in Marathi. The series of this encyclopedia known in Marathi as “Vastrodyog Mahitikosh” is being published in seven volumes.

The first three volumes (1) Tantu Nirman (Fibres Forming), (2) Soot Nirman (Yarn Forming), (3) Kapad Nirman (Fabric Forming) have already been published. The fourth volume – Rasayanik Prakriya (Chemical Processing) is in the process of printing.

The remaining volumes No.5 – Vastra Pravarane (Garment & Apparels), No.6 – Karyopyogi Vastre (Technical Textiles), No.7 – Vastrodyogatil Vyavastaphan (Management in Textile Industry) will be published in a year’s time.

- The Textile & Engineering Institute and The Textile Association (India) had successfully organized the 52nd All India Textile Conference on a very grand scale at Ichalkaranji. The conference was attended over 800 delegates on 26th and 27th October, 1996.

Silver Jubilee International Textile Conference held from 16th to 18th Feb.,2007. 26 papers were read in seven sessions on 17th and 18th Feb.,2007. 21 speakers had come from countries such as Germany, Switzerland, Italy, Belgium, Hong-Kong and China. There was an overwhelming response from educational institutes, research organizations and industry. Over 1600 delegates had come from all over the country as well as some delegates even from overseas came to attend the conference.

CONTRIBUTION TO THE LOCAL INDUSTRY AND SOCIETY :

Providing help and support to the local industry and society has always been the main activity of the institute. As a result of which the institute has a lion’s share not only in the progress, modernization and diversification of the local power loom industry but also in elevating the per capita income of this town to the highest level in the entire country.

- The Institute has conducted many seminars, conferences, training programmes as well as gives free of cost services for project report preparation etc. to encourage the local entrepreneurs for modernizing their loom. As a result of these efforts the confidence of the local powerloom owners grow and during last 5 years time over 8000 shutttleless looms have been installed which the highest in any decentralized powerloom centre in the entire country. Ichalkaranji is also known as the fastest growing shuttleless loom centre of the country.

- Kranti Garment Training Centre : DKTE along with the Ichalkaranji Municipal Council started a Garment Training Centre to provide training facilities the women from poor class in the garment manufacturing, free of cost. The Ichalkaranji Municipal Council has provided the infrastructure for this training centre. While DKTE bears all the recurring expenditure apart from providing training expertise to this centre. Till now over 5000 women has been trained. As a result of the availability of trained personals, garment industry started to grow in Ichalkaranji and today over 6000 stitching machines have been installed. All 5000 women trained at the Kranti Garment Training Centre have been found employment in the garment industry. The DKTE is thus doing a commendable job in the area of women empowerment.

- Environmental Status Report :

Institute had prepared Environmental Status Report for Ichalkaranji Municipal Council.