Mr. Sankar M., the President of Textile Machinery division of Lakshmi Machine Works Ltd, in the exclusive interview with Textile Value Chain at India ITME 2022, spoke at length on the new launches by LMW at the show and the tips to succeed for start-ups in the industry.

Tell us something about the new innovations by LMW for the India ITME 2022

In the India ITME exhibition, which is being held after six years of gap. we have brought in new technology under the banner of 4S. 4S stands for Smart Solutions for Spinning Success, as all our machines are SMART and are built to ensure success and sustainability of our customers the products on the display include.

Ringframe with RAP (Ringframe Auto Piecing), which is automatic piecing and connected to the link coner, which is indigenously developed by us in order to serve customers from start to end; i.e. from raw fibre processing to packaged yarn.

What key areas you would recommend for start-ups to be successful in the industry?

I would only recommend one or two key points. The first thing is the facility of inhouse R & D, and that’s going to play a critical role with respect to the start-ups and the inhouse R & D is the one which would be vital for success. Subsequently the modern manufacturing facility that would enable them to roll out the product with the complete ownership of process. If these two are right, I don’t see any reason for any start-ups to have any hiccup, and they would only prosper in the field whichever they embark on. I’m sure there are many examples of start-ups who have been successful this way. We’ve been successful. I think I would only like to advise all the start-ups to emulate this formula and that would enable them to be successful.

Why LMW choose to showcase its new launches in India ITME 2022 and what are its plan for global market?

At LMW, we are always striving to propel success and growth of Indian business ecosystem. Our global success does not steer our focus away from needs of Indian customers. The products which we have showcased are built on new technology indigenously developed by us and that’s why we would prefer all our new launches are done in India and some of the technology which are adaptable to the global market, we would take over there and then showcase it for our customers in the global market.

In INDIA ITME 2022, LMW launched five new machines and one new user interface system and new service called LMW PACE for life cycle services, let’s have a look at each machinery and what are the features they came equipped with.

The LMW Auto Leveller Draw Frame LDF3 2S is a high-performance machine that is designed to deliver maximum efficiency and productivity. One of its standout features is its impressive delivery speed of up to 1100 mpm, which ensures that the machine can keep up with even the most demanding production schedules. In addition to its speed, the LDF3 2S also boasts a 4 over 3 loaded drafting system with a pressure bar, which helps to ensure that the machine produces a consistent and high-quality output.

The LMW Lakshmi Auto Winder LAW 60 is a highly advanced machine that is designed to deliver optimal efficiency and productivity in yarn processing applications. One of its standout features is its ability to process a wide range of counts, from 16’s to 100’s Ne, which makes it highly versatile and suitable for use in a variety of different settings. In addition, the LAW 60 features a doffer with Fuzzy logic for efficient package removal, which helps to ensure that the machine produces a high-quality output with minimal waste. The winding head start feature is also a useful feature that helps to ensure that the machine gets up to speed quickly and smoothly, further enhancing its efficiency and performance.

The CARD LC636 S CDS and FIX FIL CAN Changer is a highly advanced machine that is designed to deliver optimal efficiency and productivity in carding applications. One of its standout features is its impressive production rate, with the ability to produce up to 250kg/hr, making it an ideal choice for use in high-volume manufacturing environments. The machine also has a working width of 1500 mm, which allows it to handle a wide range of material sizes and types. In addition, the CARD LC636 S CDS and FIX FIL CAN Changer features a swingable delivery duct for easy access, which is a patented design that helps to improve the machine’s overall efficiency and ease of use. The brass clip with improved flat (patent applied) is another useful feature that helps to ensure that the machine produces a high-quality output with minimal waste.

The Ring frame Auto Piecing (RAP) is a highly advanced machine that is designed to deliver optimal efficiency and productivity in ring spinning applications. One of its standout features is its impressive piecing cycle time, with an average time of just 35 seconds, which helps to ensure that the machine can keep up with even the most demanding production schedules. In addition, the RAP captures the broken end from the package in a unique way without lifting the package, thereby eliminating any contamination on the cop outer surface. This helps to enhance and retain the quality of the yarn, which is an important consideration for many yarn processing applications.

The Lakshmi Jet Spinning – LJS9 is a highly advanced machine that is designed to deliver optimal efficiency and productivity in spinning and yarn processing applications. One of its standout features is its seed yarn piecing system, which helps to enhance the yarn joining quality and improve the overall consistency of the output. The LJS9 also has a lower footprint of up to 40% due to its double-sided concept, which makes it an ideal choice for use in environments where space is limited. In addition, the machine is easy to operate and maintain, with a user-friendly interface and simple maintenance requirements.

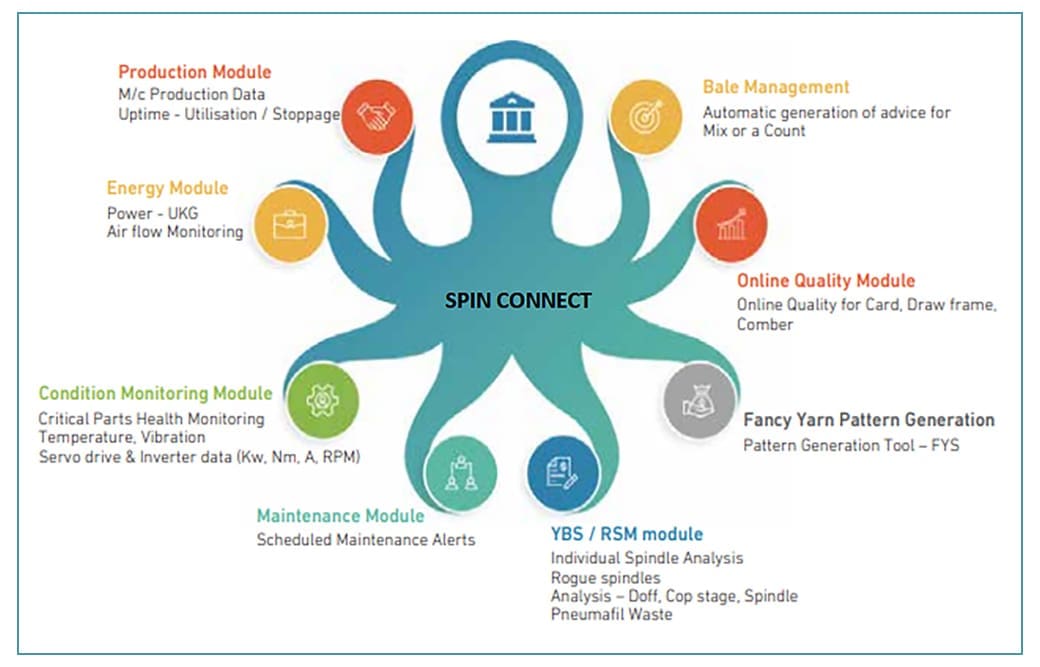

Apart from the above-mentioned machines, LMW also launched SPIN CONNCET their new monitoring and control system.

SPIN CONNECT is a revolutionary web-based monitoring and control system that is designed to provide an all-in-one solution for managing spinning mills. With its advanced digital capabilities, SPIN CONNECT connects all machinery and provides real-time information on production, quality, maintenance, and more, all in a single window. This allows the management team, technical team, and operators to monitor and manage the spinning mill with ease, optimizing processes and effectively utilizing resources to save costs and increase profits. The system’s comprehensive features make it an invaluable tool for improving the overall efficiency and performance of spinning mills. Overall, SPIN CONNECT is a reliable and effective system that is well-suited for use in a variety of spinning and yarn processing applications.

The system also has a range of additional features, including Bale Management, Online Quality Module, Fancy Yarn Pattern Generation, and Condition Monitoring Module, which help to further optimize the performance and efficiency of spinning mills. One of the standout features of SPIN CONNECT is its ability to capture drive data, including KW, A, Nm, and Rpm, which can be used to identify and troubleshoot issues with the machinery. The system also includes periodic software updates and remote software diagnosis, which help to ensure that it stays up to date and performs at its best. Overall, SPIN CONNECT is a reliable and effective system that is well-suited for use in a variety of spinning and yarn processing applications.

After the feature packed machines and latest monitoring system, LMW also launched the LMW PACE, the new life cycle services for hassle free ownership experience

The PACE stands for Professional Aftermarket Care for Excellence. LMW aims to achieve this excellence through three pathways, providing timely support on parts and components that ensure customer never loose out on productivity or quality, State of the art commissioning and technical solutions that ensure customer installation, commissioning and machine running experiences are always at the pinnacle of satisfaction, Life cycle services that ensure customer’s overall ownership experience is world class.

Through these new machines, system and new promises, LMW is showing how they care for their customer with not just verbal promises but introducing new services and products that will benefit the customer for the long run.