RABATEX INDUSTRIES – INDIA (Since 1962) have been an indispensable part of fabric industry the world over with new technological evolutions equivalent to any global know how in warp preparation machinery, fabric sampling machines , material handling and storage equipment for more than 6 decades. Thus, the vacuum which the Indian fabric industry has been subjected to once, could be eliminated by advanced technological import substitute machinery.

Rabatex experts have been interacting with the technical experts in the textile industry across the world over their actual requirement with respect to value for investment as well as product output expectation. With patience and creation ability, Rabatex Team has made a detailed analysis of the future demand and customer expectations as well as global opportunity for the Indian Textile Fabric Manufacturing Industry. Rabatex decided to help the Indian textile industry in exploring the opportunities in displaying its creativity and value addition capabilities. Rabatex is pioneer in manufacturing state of art Warp Preparatory Machinery / Fabric Sampling Solutions / Material Handling and Storage Equipment / ASRS (Vertical Lift Module) and enjoys major market share in India as well as global markets in more than 36 countries across globe. Key markets in which Rabatex witnessed higher growth include USA, CANADA, TURKEY, RUSSIA, SOUTH AFRICA , INDONESIA , BANGLADESH , UKRAINE and INDOESIA etc.

Customer satisfaction is always at the core for us while our products & services are built around this core. We always look forward to staying abreast in technology for delivering quality performance to our customers. Maintaining the leadership position in all the markets being our key objective, Rabatex would continue to strive for being a leading global player and capture a considerable share in all textile-producing countries.

Rabatex Industries is the largest supplier of weaving preparation products manufactured in India. There are already about 3200 Nos. of Sectional Warpers & Fabric Sampling Machines & about 5600 Material Handling and storage equipment working across the world. More details about products can be viewed on www.rabatex.com

Rabatex’ newly launched products developed for fabric sampling solution are installed globally including USA, Turkey, Indonesia and some in India at Nandan (Chiripal Group ) , Shahi Exports , Saam Textiles , Nitin Spinners , Sangam Group , Kanchan Group , Rajapalayam Mills , Birla Century and many more.

A textile sample is a piece of cloth or fabric designed to represent a larger whole fabric. A small sample, usually taken from existing fabric, is called a swatch, whilst a larger sample, made as a trial to test print production methods, is called a strike off. For plain-dyed fabrics it is called a lab-dip, and for yarn-dyed fabrics (like stripes and checks), it is called a handloom samples.

The use of swatches has formed an essential part of the design process of textiles throughout different cultures across history. Samples enable designers to display different types of fabric, demonstrating how different colours, materials, trims and methods of weaving will look in real terms—something that may not be readily apparent from a paper of digital design—before the entire fabric is manufactured.

A textile manufacturer may bring together several swatches of materials into a single sample book, which may serve to enable a salesperson to display a wide selection of fabrics to potential customers in a convenient manner. A textile swatch book may also serve as an internal reference for materials that have been made previously and could be manufactured again.

New trend in the fashion industry is that brand promoter or designer need to feel fabric as actual garment as well as to test market with small quantity of garment, where Advanced Sample warper makes major roll to prepare a short length actual warp with minimum quantity of warp yarn with unlimited design or pattern possibility. This process improves highest success ratio of any new product promotion effectively with actual test market results. Apart from this the customisation of the fabric need is increasing day by day where user needs to have specific design or pattern of fabric, which can be fulfilled with use of this technology.

RABATEX Industries have been an indispensable part of fabric industry the world over with new technological evolutions equivalent to any global know how in warp preparation machinery, fabric sampling machinery and material handling and storage equipment for more than 6 decades. Thus, the vacuum which the Indian fabric industry has been subjected to once, could be eliminated by advanced technological import substitute machinery.

Rabatex experts, have been interacting with the technical experts in textile industry across the world over about their actual requirement with respect to value for investment as well as product output expectation in quickest fabric sampling solution. With patience and creation ability, Rabatex Team has made analysis of the need of the future demand and customer expectation as well as global opportunity of Indian Textile Fabric Manufacturing Industry.

RABATEX has now come out with a complete range of Fabric Sampling Solutions like Small Width Fabric Weaving Machine, Small Width Single End Warper, Cone to cone sizing and Advanced Sample Warper for short length preparation which has its unique features to submit. Of course, the added advantages or special features which every RABATEX brand products always carry have been fed into this new launch also. More than 6 decades of tradition inspires them to come out with something new every time for their patrons.

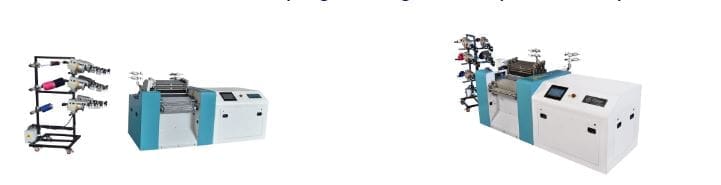

Fabric Sampling Weaving Machine ( Small Width)

Sample Weaving Machine technical specifications : Working Width – 20” ( 50CM / 500mm ) / Maximum Fabric Sampling length – 30 Meter / No of Weft Selector – 8 / No. of Shaft – 20 / Auto Weft Selector / Close Loop Control for Speed and Tension / Fully PLC Controlled

Sample Weaving Machine technical specifications : Working Width – 20” ( 50CM / 500mm ) / Maximum Fabric Sampling length – 30 Meter / No of Weft Selector – 8 / No. of Shaft – 20 / Auto Weft Selector / Close Loop Control for Speed and Tension / Fully PLC Controlled

Single End Sample Warper (Small Width)

Small width sample warper technical specifications : Working Width – 20” ( 50CM / 500mm ) / Maximum Fabric Sampling length – 30 Meter / No of Weft Selector – 8 / Leasing Operation – Automatic / Thread Selection – Automatic / Pattern Entry – Infinite / Fully PLC Controlled

Cone to Cone Single End Sizing Machine

Single end cone to cone sizing machine technical specifications : Heating Type – Electrical / No of Spindles – 1 or 4 or 8 /Maximum Speed MPM – 250 MPM / Length Set Control – Yes / Temperature Control – Yes / Speed Control – Yes / Spindle Control – Individual

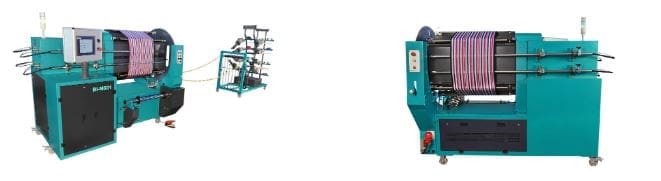

Advanced Sample Warper with 16 Feeder Rotary Creel

Advanced Full Width Sample Warper Machine Technical specifications : Maximum Possible Length – 500 Meter ( 700 Meter on Request) / Maximum Warp Feeder – 16 / Maximum Warping Speed – 1000MPM / Maximum Beaming Speed – 50MPM / Cross Lease Automatic – Yes / Knot Lease Automatic – Yes / 7 Lease Automatic – Yes ( Optional ) / Pattern Optimizing Software – Yes

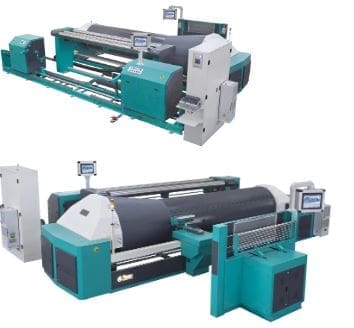

Advanced Sectional Warper

Advanced Sectional Warper Machine Technical specifications :::: Working Width – 1800 to 5000mm / Maximum Flange Dia – 800 to 1250mm / Maximum Warping Speed – 1000 MPM / Maximum Beaming Speed : 200MPM / Auto Beaming Tension Control / Auto Warping & Beaming Line Speed Control / PLC Controlled Leasing Device / 3 Axis Servo Control / Laser Sensor for Warp Density Calculation and feed / Maximum Beaming Tension – 7500N to 40000N /15” 2 HMI on Both Side

——————————————————————————–Rabatex’ Journey————————————————————————————

1962 (Manual) ………………………………….………………………………………………………………………….…………………….………2023 (18 Axis Control Machine)