Vasant R Kothari

Assistant Professor, DFT, NIFT Bangalore

&

Gigy Elizabeth

MFT, NIFT Bangalore

(Author can be contacted @ www.vasantkothari.com)

Zipper, zip fastener, slide fastener or simply a zip is a mechanical wonder of the fastener family which has greatly simplified our lives. Although the first patent on zippers came as early as 1851, it was a long way up for zippers and it became highly popular only during the last few decades, thanks to the promotions by the fashion industry, especially the campaign of 1930s for kid’s clothing with zippers. The wide acceptance owes to its convenience, efficiency, ease of use and functionality. Today no civilized man can think of a day without zipping updue to its extensive application in most of the daily stuff we use, from slacks, trousers, jeans, jackets, backpacks, shorts, skirts, dresses, bags and shoes to camping gears and tents.This article takes you on a quick journey through this “little part which makes a big difference” to our lives.

Definition

The Oxford English dictionary defines a zipper as “a device consisting of two flexible strips of metal or plastic with interlocking projections closed or opened by pulling a slide along them, used to fasten garments, bags, and other items”. They form a temporary continuous closure and can be even made water-tight, air-tight, anti-static or fire resistant. The popular alternatives to zipper are buttons, hooks or hooks and fasteners (Velcro). The appropriate choice for an application depends on the garment and its functionality. For warm clothing like winter jackets, zipper is a better choice over buttons since it provides a continuous closure which protects the user from cold air. Buttons are more appropriate for shirts, blouses and dresses where the bulk which the zipper adds is undesirable. Also, its inherent stiffness makes it more appropriate to flat surfaces than to bloused or draped areas.

Evolution

The evolution of zipper is a demonstration of human ingenuity and determination to devise a “better way”. The origin of zippers can be traced back to 1851, when Elias Howe, the inventor of sewing machine, received a patent for “Automatic, Continuous Clothing Closure”. However, he was more focused on the sewing machine that he didn’t pursue it any further. Thus the credit of inventing the zipper went to Whitcomb Judson, who marketed a “Clasp Locker” about 40 years later (1893), which was designed as an easier solution for securing high-button boots. But the modern zipper was designed by Gideon Sundbäck by 1913. Heworked for the Universal Fastener Company which was launched by Judson to market his product. The name “Zipper” was coined by B.F.Goodrich – onezip of handwith a “zzip” sound is all that is required for fastening; hence the name. The real boost for the zippers came in the 1930s when it was marketed for kids’ clothing – promoting self-reliance in children, owing to its ease of use. The French fashion designers started using zippers in men’strousers and by 1937 the zipper beat button in popularity to become the most widely used fastener in apparels.The models that could be opened on both ends were the next big thing in zipper’s history. The story is not finished yet and the zipper is still evolving.

Component Parts

Before going into any further discussion, let us understand the component parts of a zipper. The zipper consists of two rows of teeth (gears or elements), oneon either side of the opening, which interlock to close the opening. When the teeth are closed, the assembly is called a chain.The Y shaped channel of the slider meshes together or separates the opposing teeth, depending on the direction of movement of the slider. The teeth can be individual units (Tooth style) or continuous coils (Coil Style), attached to tapeson either sideby stitching, weaving in, knitting or molding. There could be a top stop, bottom stop, box-pin or pin-pin arrangement at the ends,based on the separabilityrequirement of the zipper opening. The tape is usually made of polyester, but sometimes synthetic fiber tape,cotton tapes or vinyltapes are alsoused and can be either woven or knitted.

Before going into any further discussion, let us understand the component parts of a zipper. The zipper consists of two rows of teeth (gears or elements), oneon either side of the opening, which interlock to close the opening. When the teeth are closed, the assembly is called a chain.The Y shaped channel of the slider meshes together or separates the opposing teeth, depending on the direction of movement of the slider. The teeth can be individual units (Tooth style) or continuous coils (Coil Style), attached to tapeson either sideby stitching, weaving in, knitting or molding. There could be a top stop, bottom stop, box-pin or pin-pin arrangement at the ends,based on the separabilityrequirement of the zipper opening. The tape is usually made of polyester, but sometimes synthetic fiber tape,cotton tapes or vinyltapes are alsoused and can be either woven or knitted.

Sliders can be classified based on their locking mechanism as automatic lock slider, non-locking slider, pin locking slider, cam lock slider, flange lock slider, rachet lock slider and releasing slider. The stops can be top stop, bottom stop, releasing stop or bridge stop.

Types

There are mainly two types of zippers based on material used for the construction of tooth – metal and plastic zippers.

Metal zippers can be either with – (i) flat or profiled metal wire teeth clamped around the edge of a beaded tape; made from brass, aluminium, nickel or white brass (nickel free). (ii) zinc metal teeth die-cast directly on to the tape. Metal zippers can be of various finishes such as golden brass, antique brass, antique silver,antique copper,black oxidized, manganese, aluminium,gunmetal etc; even gold finish is also available for high end luxury clothing.

Plastic zippers can be classified as

- Coil Zippers – These are the most widely used zippers worldwide. They are made of polyester and hence called polyester zippers. They are also called nylon zippers as nylon was used in earlier days for their production. They can be further classified as

- LFC Zippers (Ladder Coil Type or L Type or Ruhrmann type) made with coils in ladder form, stitched on to the tape. They are mostly used only in South Asia now.

- CFC Zippers made with spiral coil, and having a chord running inside the coils.There is a special class of CFC zippers known as Invisible zippers. They are made and stitched in such a manner that only a hairline seam is visible from outside and do not require provision of a fly. They are predominantly used in ladies dresses and skirts. These zippers are available in both knitted and woven tapes.

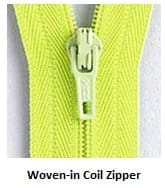

- Woven-in Coil Zippers which are thinner and more durable than regular coil since the elements are woven into the tape directly.

- Plastic Molded Zippers – The teeth are made frompolyacetalpowder and are directly injected or molded on to the carrier tape.They are popularly known as Delrin® or VISLON® (Delrin® is a registered trademark of E. I. du Pont de Nemours and Company;and VISLON® is a registered trademark of YKK Corporation in Japan and other countries/regions.)

Plastic extruded zippers– consists of separate zipper strips having complimentary profiles which are separably interengagable. Mainly used in bags and packing solutions.Ziploc is a popular brand of reusable, re-sealable zipper storage bags. (Ziploc® is a registered trademark of S.C. Johnson and Son, Inc.)

Plastic extruded zippers– consists of separate zipper strips having complimentary profiles which are separably interengagable. Mainly used in bags and packing solutions.Ziploc is a popular brand of reusable, re-sealable zipper storage bags. (Ziploc® is a registered trademark of S.C. Johnson and Son, Inc.)

Some other zipper categorizations are:

- Separating Zippers – Also known as open-ended zippers in which the complete separation of the twostringers is possible. A box and pin mechanism is used to lock the two sides of the zipper into place, and are often seen in jackets.

- Non–Separating Zippers – The complete detachment of the stringers is not possible. They can either be one-end-closed non-separating zippers (usually found in trousers, skirts, boots etc.)or closed-ended zippers which are extensively used in luggage bags.

- One-way Zippers – They have only one slider which operates in one way.

- Two-way Zippers– There will be two sliders operating in the zipper. Can be either X-Type (tail-to-tail) or O-Type (head to head). The zippers are made in #5 or larger sizes.

- Loop Zippers – These zippers do not separate at the top end, but forms a loop; used mainly in hoodies, continuous necklines etc.

- Top Open Zipper – Enables to quickly open the zipper from the top by pulling up the slider using a little more pressure than usual.

- Double pull Zippers – These zippers have got two tabs one on each side of the slider and is usually used in reversible garments, tents etc.

- Reversible (Flip-Over) Pull Zippers – The zipper pull has a single tab which flips over the crown of the pull; used for reversible garments or zip-in linings.

Application Types

The zippers can have a centered application where the zipper teeth are centered under the opening, in which the two folds of fabric on each side are abutted. This application is most commonly found on separating zippers. The main disadvantage is that the zipper cannot be concealed completely. This could be overcome in the case of a lapped application where one side overlaps the other. This is more widely used. Fly front is a variation of this application. Another application of zippers is that in which the zipper cannot be seen at all. This application makes use of special invisible zippers. A zipper can sometimes have an exposed application also, if it is a part of the design of the garment.

Size Specification

Now we will try to understand the size designation of the zippers. The size of a zipper is represented as a number which denotes the approximate width of the chain in mm, when the teeth are closed. For example a #5 zipperwill have a chain width of around 5mm. Zippers are usually made from #2 to #25, the most common ones being #3 and #5. The zippers can be categorized like below, based on their numbers.

- Small – includes sizes 2, 3, 4, 4.5, 4.9 of most metal, coil and plastic zippers.

- Medium – includes sizes 4.9, 5, 6, 7, 8 for metal coil and plastic zippers and size 8 for coil zippers.

- Large – includes sizes 8, 9 of coil and plastic and metal of size 10

Selection Criteria

Selecting the right zipper is critical, not only from aesthetic point of view, but for its functionality as well and the wrong choice may have heavy financial implications. A zipper should match in quality with the garment – not higher and not lower. If a zipper fails in a garment, it is usually difficult to repair it and the garment may have to be discarded, which leads to customer dissatisfaction. The selection of the zipper is influenced by the type of garment, the type of fabric, any special processing done to the apparel, strength and performance requirements and, of course, the fashion requirement.

The application scenario of widely used zipper sizes and types are given in the below table:

Ordering Parameters

Also, great care should be taken while ordering the zippers. For example, care should be taken to ensure that the length of the zipper is measured from top of the top stop to the bottom of the bottom stop (for close-ended zippers) or the box and pin (for open-ended zippers). Similarly, in the case of separable zippers, it should be clarified if the insertion required is right hand or left hand. The usual parameters specified while ordering are the size, type of zipper (whether the zipper is metallic, plastic, LFC or CFC, #3 or #5, closed end or open end, woven or knitted, one way or two way etc.), type of slider, length, colour, finish, quantity, quality delivery date and any special requirements (AZO free, nickel free, heavy metal free etc). Colors can be selected from the standard shade card provided by the manufacturer and if an exact match is not available, can opt for DTM (Dye-To-Match) with fabric swatch, but this may require more time. Sometimes, when exact matching is extremely difficult, as in the case of multi color fabric, mixed yarn, velvets or fabric with sheen, computer matching is done to confirm the match.

Sourcing and Lead Time

Zippers have to be ordered relatively early in the apparel production timeline and is usually done as a part of the pre-production process to avoid any delay in production due to its unavailability. The average lead time for zippers is 7 – 15 days for domestic sourcing and 15 – 25 days for international sourcing. In the case of DTM, an extra lead time of about 5-7 days may be required. Supply chain for zippers in the country is strong, both domestic and international manufacturers and suppliers being present in the market. A large portion of the zippers are manufactured by YKK. In fact, each third zipper is made by YKK Company and each fourth one by TALON. Almost all the rest are made in Southeast Asia, mainly in Bangladesh, China and India.

Factors Affecting Cost

There are various factors which affect the cost of a zipper apart from the quantity ordered, like the size,composition and type of the chain; whether it is open ended or closed ended, one way or two way, reversible or not; the material of the tape, whether it is printed or embellished; slider and pull type, and even the mode of package – roll form or piece form. For the same chain size, coil is the cheapest one followed by plastic molded; the metallic ones are costlier. Again the price goes up for any special finishes and design elements.Minimum orders are generally based on the gauge and style of the zipper ordered.The minimum order quantities on an average are 1000 pieces for regular items and 15,000- 20,000 pieces for customized items in the case of domestic sourcing and 10,000-15000 pieces and 40,000-50,000 pieces respectively for international sourcing.

Quality Tests

The quality of the zippers can be ascertained through various tests. Various standard test methods are specified by ASTM like tests for measuring zipper dimension, durability of finish of zippers to laundering, colorfastness of zippers to dry cleaning, colorfastness of zippers to light,colorfastness of zipper tapes to crocking,colorfastness of zippers tolaundering,durability of finish of zippers todry cleaning, resistance of zippers to salt spray (fog), operability of zippers etc. Apart from these, there are test methods for testing the strength of zippers like holding strength of separable units, holding strength of slider lock, holding strength of stops, resistance to angular pull-off of slider pull, resistance to cushioned compression of sliders, resistance to pull-off of slider pull, resistance to twist of pull and slider, slider deflection and recovery and strength of chains and elements.Similarly specifications are provided by other institutions like British Standard Institution (BSI), Japanese Industrial Standard (JIS) etc.

Zipper Defects

The zippers can have the following defects:

Slider Defects – can be locking defect, faulty dimension, crushed slider, tarnishing, burrs or rough spots, interference of lock prong with the movement of slide, weak slider bodies etc.

Chain or Teeth Defects – this includes improper dimension, mismeshed and unmeshed teeth or coil, missing teeth, misplaced teeth, humpy chain, curved or crooked chain, discoloration, exposed cord, cord not attached to tape, coil not securely attached to fabric and improper zipper length.

Top or Bottom Stop Defects – top or bottom stop missing, improper dimension and improper location of stops.

Tape and Cord Defects– can manifest as lack of color fastness, holes and cuts, uneven edge, narrow or varying width,reeding and off-color.

As any other component, the zippers also have to be given proper care for its proper functioning and durability. If the garment has to undergo washing, there is a possibility of color change of metal zippers due to oxidation caused by chemical agents used in the wash. Suitable zipper should be selected after proper testing. Similarly there are chances of color fading of the sliders due to the peeling off of the electro plated coating. Also there are chances of slider or puller breaking during washing. The garment should be put in laundry bags, zipped up, turned inside out or the sliders should be wrapped up with fabric before washing.

During usage also, the zipper should be maintained properly by following the instructions provided by manufacturers for opening and closing of the zipper, ironing and cleaning etc.

Child Safety Guidelines

While choosing zippers for baby / infant clothing, it is essential to follow certain guidelines in order to make it child friendly. Plastic top stops are preferred to avoid possible scratching. Since needle detection is mandatory to insure safety from broken needles, it is preferred to use materials that are not detected by the process. In order to avoid possible nickel allergy, it is recommended to use nickel free zippers in kids garment. Pin lock sliders should be avoided to avoid injury by sharp points. Zippers with top stops are highly recommended for infant clothing to avoid choking hazards. Use zippers that meet standard torque and tension tests recommended for infant clothing.

Innovations

All the major zipper manufacturing companies are dedicatedly pursuing research and development activities leading tomany innovative solutions. The most recent remarkable innovation is a revolutionary concept developed by YKK and launched in February this year in ISPO Munich 2012 –a leading international sports business networktrade fair – The “Ultra Light Zipper” which is a response to the ongoing lightweight trend in sports and outdoor apparel. The innovation has no teeth, is flexible, highly packable and requires no sewing. The zipper chain is directly applied on a wide breathable membrane fabric, decreasing the weight of the whole garment.

Sustainability

Our discussion about zippers will not be complete without a mention about the green initiatives in zipper industry. These little parts are often produced in terrible conditions with polluting materials. Therefore, truly 100% earth-friendly products should take care of this aspect also. The green touch in a zipper can be in the material used (tape which uses 100% recycled polymer fabric or fabric with organic cotton, the metal parts with non-electroplated finishes which lighten the impact on environment) or it can be in the manufacturing process (reducing the expulsion of waste water, use of cutting-edge energy conservation equipment and transition to fuels that have low harmful emissions, using natural substitutes for harmful chemical substances etc.) YKK claims to be the first zipper company to promote environmental protection measures and developed a line of environmentally friendly zippers. The figure below shows the road map for this initiative.

A zipper can never make a garment, but it can surely break it. So be careful with your zipper choice. It really makes a big difference.

References

- https://www.randomhistory.com/zipper-history.html

- https://en.wikipedia.org/wiki/Zipper

- https://www.sewingmantra.com/index.php/sewing/the-origin-and-history-of-zippers/

- https://www.innovationintextiles.com/industry-talk/ykk-launches-revolutionary-zipper-concept/

- https://www.blogvasion.com/2007/12/zipper-industry-and-global-market.html

- https://www.lcbzipper.com/eng/product/zirtes.htm

- https://www.lcbzipper.com/eng/prti/guhoz.htm

- https://www.google.com/patents/US4792240

- https://www.zippersource.com/guide/

- https://industrycodes.com/publishers/be2bde/astm-international/categories/61-clothing-industry

- https://www.garmento.org/quality/Glossary_of_Defect_Terminology.pdf

- https://www.ykkfastening.com/products/zipper/vislon_zipper/top_open.html

Image Courtesy

- https://www.ykkfastening.com/products/zipper/vislon_zipper/vislon_standard.html

- https://www.eaton.com/Eaton/ProductsServices/PlasticExtrusion/ZipMateZippers/index.htm

- https://www.innovationintextiles.com/industry-talk/ykk-launches-revolutionary-zipper-concept/

- https://en.wikipedia.org/wiki/Zipper

- https://www.ykkfastening.com/products/zipper/coil_zipper/eflon_woven_in_type.html

- https://www.ykkfastening.com/products/zipper/coil_zipper/graphic.html

- https://www.indiamart.com/singhalzippers/polyester-cfc-zippers.html

- https://www.indiamart.com/seafullpacific/zippers.html

- https://nbeasytrade.en.made-in-china.com/product/NMOEegXVAmlz/China-3-LFC-Zipper-CE.html

- https://www.textileschool.com/School/Apparel/GarmentAccessories/TypesofZipper.aspx

- https://www.jaycotts.co.uk/acatalog/_Reversible_Flip-Over_Zips.html