Fabric for Automotive Textiles

M. Landage and R. S. Dhumal

D.K.T.E. Society’s,

Textile and Engineering Institute,

Affiliated to Shivaji University,

Ichalkaranji 416 115, Maharashtra, India

Abstract

The use of nonwoven in technical textile is increasing worldwide. Nonwoven fabrics are mainly manufactured by using synthetic fibers like polyester. Synthetic fibres show more flammable properties. In automotive textiles flame retardant finish to automotive interiors gives safety feature. Use of textile materials in increasing in automotive industry as it gives comfort and safety to passengers. Comfort, safety and weight saving are important in automobile industry. It is observed that, nonwoven polyester fabric has proven its worth in exhibiting as flame retardant finished fabric in automobile industry. Also it is observed that, the 300 GSM nonwoven fabric finished with 150 gpl concentration of flame retardant and cured at 200OC shows highest ignition time 7.95 sec amongst all the treated samples, which shows good flame retardancy property.

Keywords: Automotive, Flame-retardant, Nonwoven fabric, Synthetic fibres, Textiles.

- Introduction

The flammability of synthetic fibres is a major issue that represents highly flammable products. Flame retardant finishes can be applied to synthetic fibres and fabrics to resist the burning. Nonwoven fabrics are manufactured using synthetic fibers like polyester are most commonly used for making of nonwoven fabric at present time. Nonwovens are replacing woven fabrics in major application areas that requires flame retardation. Polyester, in particular, melts rapidly with a bead formation without leaving char residue and relatively with low amount of smoke.

Fire risk increases with the use of nonwovens which are manufactured using synthetic fibers. There are different types of finishing treatments, using that treatments flame retardant properties are imparted to the synthetic materials. Only few treated fabrics are laundered and dry-cleaned with keeping flame retardant properties. These treatments are referred as durable flame retardant finish. Flame retardancy of nonwoven can be obtained in two ways one is mechanically blending flame retardant chemical with polymer before extrusion and another is by giving topical treatment to the fabric. Topical treatments are useful with thermosets, thermoplastics and additive are only useful with thermoplastics.

- Experimental

Raw Material:

Polyester needle punched nonwoven fabric : 100, 200 and 300 GSM.

Chemicals used:

- Flame retardant agent: (APYROL PEL)

- Wetting agent : Kleenox BAS paste

Flame retardant chemical is applied by varying concentration from 50 to 150 gpl, and temperature from 180 to 200OC on 100, 200 and 300 GSM of fabric.

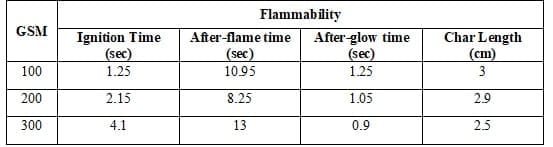

Table 1. Flammability testing of needle punched nonwoven fabric before treatment

Application method:

Formulation of finishing recipe:

For the preparation of the finishing recipe, requisite quantity of flame-retardant agent along wetting agent (1gpl) is used. The mixture is stirred well with the help of stirrer until components were dissolved completely and applied by pad-dry-cure technique.

- Results and Discussion

Effect of treatment on flammability of fabric

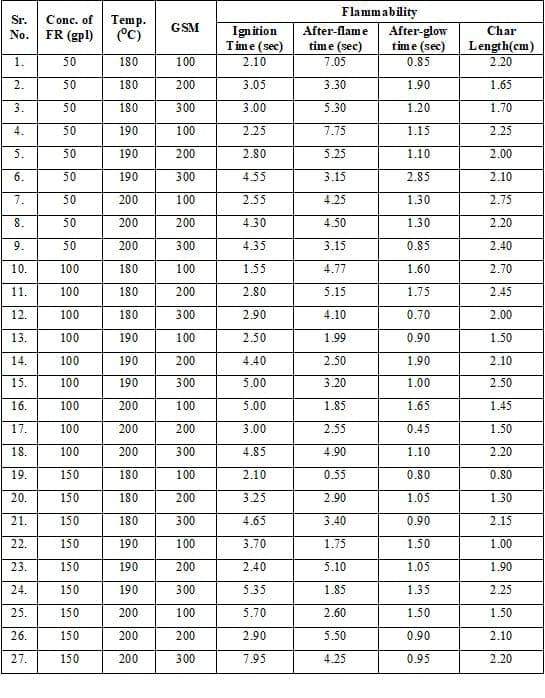

Table 3.1 Effect of concentration of flame retardant and temperature of curing on Flammability of fabric

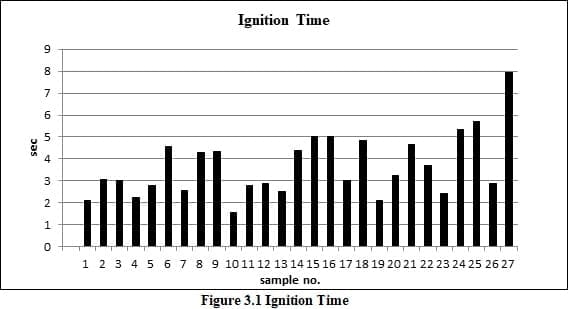

3.1 Effect of treatment on Ignition Time of fabric

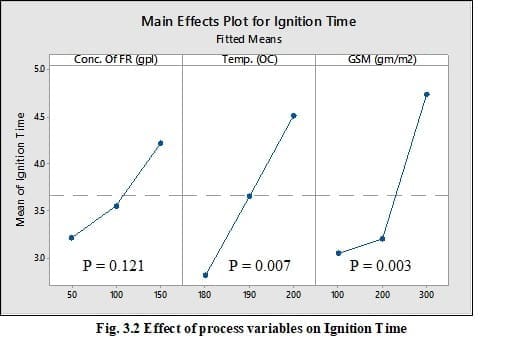

From table 3.1 and figure 3.1 and 3.2, it is observed that the ignition time of nonwoven fabric samples was unaffected due concentration of flame retardant (P = 0.121), There is no significant effect of finish on the ignition time of the fabric. The ignition time of polyester nonwoven fabric does not change significantly (at 5% level of significance) after application of flame retardant finish. This may be because the amount of deposition of flame retardant chemical on to the surface of nonwovens, but it is affected due to GSM of fabric and and temperature of curing (P = 0.003 and P = 0.007 respectively) at 5% level of significance. This may be because of as GSM varies from 100 to 300 gm/m2; the needle punch density also number of fibres contributing per unit area also increasing and as the time of curing increases there will be more amount of flame retardant chemicals fixes on surface of fabric resulting in increase in the ignition time of fabric. The nonwoven fabric with 300 GSM and finished with 150 gpl concentration of flame retardant and cured at 200OC shows ignition time 7.95 sec amongst all the treated samples, this may be because as this particular sample consist of higher concentration of flame retardant chemical and higher curing temperature resulting in more fixation of chemical on to the surface of fabric.

3.2 Effect of treatment on After-flame Time of fabric

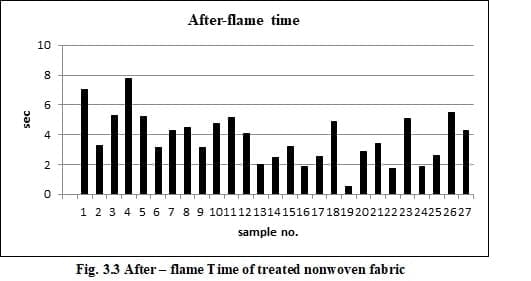

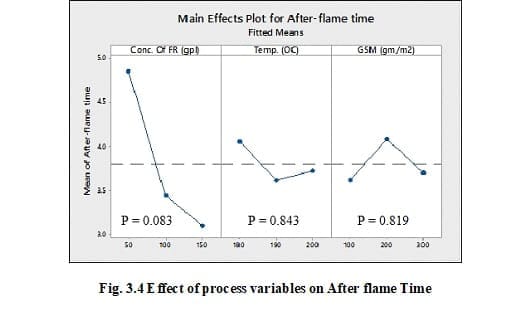

From table 3.1 and figure 3.3 and 3.4, it is observed that the after flame time of nonwoven fabric samples was unaffected dueconcentration of flame retardant, GSM of fabric and temperature of curing (P = 0.083, P = 0.843, P = 0.819 respectively). There is no significant effect of finish on after flame time of the fabric. The after flame time of polyester nonwoven fabric does not change significantly (at 5% level of significance) after application of flame retardant finish. Also, it is observed that, there is less significant effect of concentration of flame retardant chemical on to the after flame time.

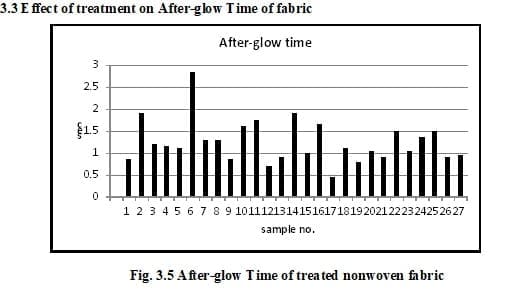

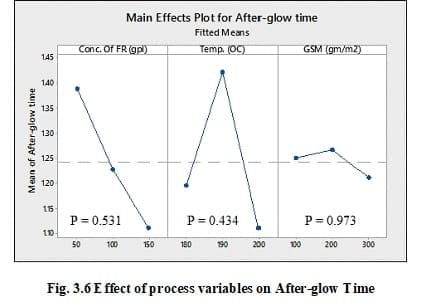

From table 3.1 and figure 3.5 and 3.6, it is observed that the after-glow time of nonwoven fabric samples was unaffected dueconcentration of flame retardant, temperature of curing andGSM of fabric (P = 0.531, P = 0.434, P = 0.973 respectively). There is no significant effect of finish on after-glow time of the fabric. The after-glow time of polyester nonwoven fabric does not change significantly (at 5% level of significance) after application of flame retardant finish.

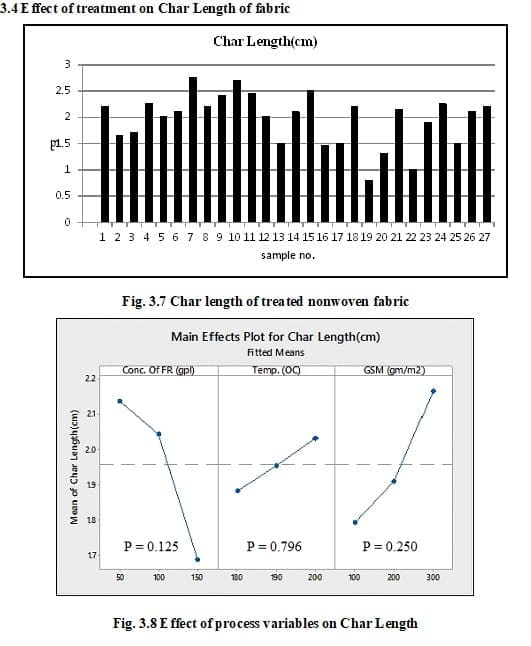

From table 3.1 and figure 3.7 and 3.8, it is observed that the char length of nonwoven fabric samples was unaffected due concentration of flame retardant, temperature of curing and GSM of fabric (P = 0.125, P = 0.796, P = 0.250 respectively). There is no significant effect of finish on char length of the fabric. The char length of polyester nonwoven fabric does not change significantly (at 5% level of significance) after application of flame retardant finish. The 100 GSM nonwoven fabric finished with 150 gpl concentration of flame retardant and cured at 180OC shows char length 0.80 cm amongst all the treated samples, this may be because as the sample is only 100 GSM and also number of fibres contributing to the given area is less. As less number of fibres are available for burning, less char is obtained.

Conclusions

The application of flame retardant in automobile textile targets for improving the functionalities of materials or give it new a features. After analyzing the results, statistically, it is observed that the 300 GSM nonwoven fabric finished with 150 gpl concentration of flame retardant and cured at 200OC shows highest ignition time 7.95 sec amongst all the treated samples, which shows good flame retardancy property. The 100 GSM nonwoven fabric finished with 150 gpl concentration of flame retardant and cured at 180OC shows lowest after flame time 0.55 sec amongst all the treated samples, which shows good flame retardancy property. The 100 GSM nonwoven fabric finished with 150-gpl concentration of flame retardant and cured at 180OC shows 0.80 cm amongst all the treated samples for excellent flame retardancy property and lowest char length. The present study reveals that the 100 GSM nonwoven polyester fabric finished with 150 gpl of flame retardant chemical and cured at 180OC gives better results. Nonwoven polyester fabric has proven its worth in exhibiting as flame retardant finished fabric in automobile industry.

References

- Parmara M S, et al, “Study on flame retardant properties of poly(lactic acid) fibre fabrics”, Indian Journal of Fiber & Textile Research Vol. 39, September 2014, pp. 268-273.

- Mazharul Islam Kiron, “An Overview of Flame Retardant Nonwoven Fabrics”,https://textilelearner.blogspot.com/2013/04/an-overview-of-flame-retardant-nonwoven.html 29 Dec 2017

- Thiruma Mariappan, “Fire Retardant Coatings”, https://dx.doi.org/10.5772/67675

- Subhas Ghosha & Sukanya Krishnan, “Application of poly (lactic acid) fibres in automotive interior”, Indian Journal of Fiber & Textile Research Vol. 32, March 2007, pp. 119-121.

- Schindler W. D. and Hauser P. J., “Chemical finishing of textiles”, published by Woodhead Publishing Limited, England 2000.

- Fung Walter and Mike Hardcastle, “Textiles in automotive engineering”, Published by Woodhead Publishing Limited, England 2001.