US’ scientists have used natural plant products called cellulose nanocrystals to coat and pin carbon nanotubes uniformly into the carbon-fibre composites, to increase their strength and impart other desirable properties such as high electrical and thermal conductivities. The team says this method of coating nanocrystals is quicker than conventional methods.

In current technology, polymers reinforced with ultra-fine strands of carbon fibres represent a class of composite materials that are “as light as a feather and as strong as steel,” leading to versatile applications in several industries. To increase strength and give carbon-fibre composites other desirable properties such as high electrical and thermal conductivities, carbon nanotubes are often added.

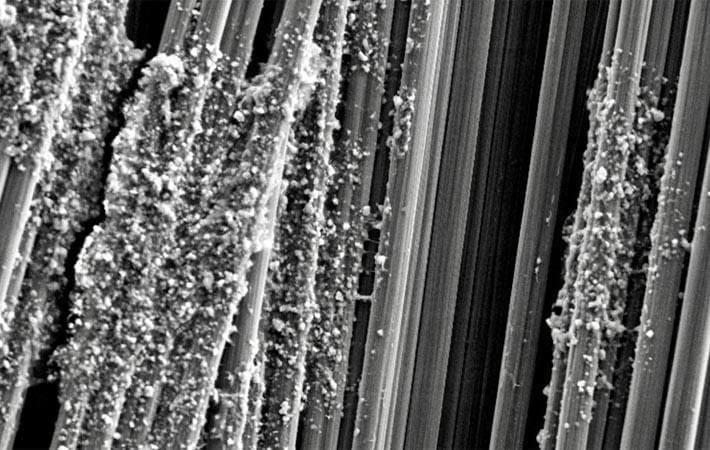

However, the chemical processes used for incorporating the carbon nanotubes into these composites often cause the nanotubes to spread unevenly and clump, reducing the overall benefit.

To facilitate the even distribution of carbon nanotubes, researchers in a US National Science Foundation-funded study at Texas A&M University used natural plant products called cellulose nanocrystals to coat and pin carbon nanotubes uniformly into the carbon-fibre composites.

The researchers said their method is quicker than conventional methods and allows for the designing of novel carbon-fibre composites. The results are published in the journal Applied Nano Materials.

“The incorporation of cellulose nanocrystals into carbon nanotube/carbon fibre polymer composites creates a lightweight but tough material with potential applications in the aerospace, automotive, marine and defence industries,” says Khershed Cooper, a programme director in NSF’s Directorate for Engineering. “The use of recycled wood waste to extract cellulose nanocrystals makes it an environmentally benign process.”

Composites are built-in layers. For example, polymer composites are made of layers of fibre, such as carbon fibre or Kevlar, and a polymer matrix. This layered structure is the source of the composites’ weakness. Any damage to the layers causes fracture, a process technically known as delamination.

To facilitate the even distribution of carbon nanotubes, the team turned to cellulose nanocrystals, compounds easily obtained from recycled wood pulp. The researchers found that the unique molecular structure offers the ideal solution to construct composites at the nanoscale.