By ITMA Organiser, 14 Sep 2023

Fully integrated technologies with up-to-the-minute automated features for the end-to-end production of fully-finished garments and home textiles are in abundance, as showcased by exhibitors on ITMAconnect. Technologies such as artificial intelligence (AI), machine learning and automation are becoming increasingly important in the textile industry, and new machines and software can significantly streamline production and improve efficiency.

AI-powered systems can, for example, help detect defects in fabrics and garments during manufacturing processes. Predictive maintenance is another benefit, monitoring machines to help prevent breakdowns and reduce downtime. AI is also proving valuable in R&D by enabling data from different sources to be coordinated in order to optimise product design and reduce time and costs via the sensor-controlled optimisation of a host of different parameters.

Read on to find out how AI-powered systems can help production lines and how some of the technologies featured on ITMAconnect uses automation.

Discover more automated software and solutions on ITMAconnect. Explore >> Exhibitor List >> Companies, and search using the keyword “Automation”.

Machine Learning with AI

With nearly 70 years of expertise in yarn sensor technology, Eltex of Sweden AB has consistently been at the forefront of new product development.

Its EYE and EyETM systems are capable of accurately and efficiently monitoring the movement and tension of more than 1,000 yarns simultaneously. These systems are suitable for various applications and fibre types, including warping, winding, multiaxial weaving and new material applications.

In addition, Eltex sewing tension monitors, such as the ETM422, have been increasingly well-received. This high-precision device can monitor the tension of sewing threads real-time, effectively improving the quality and safety of the sewn products. Particularly in the automotive manufacturing sector, the ETM422 has seen widespread use to meet the industry’s escalating demands for product safety and quality.

All of these devices and systems are smart, digitalised and capable of seamless integration with higher-level factory systems, enhancing intelligent manufacturing capabilities.

Augmented reality

With over 10,000 cutting systems installed worldwide, the Bergamo, Italy-based FKgroup‘s CAD software is central to cutting room automation and the processing of garments with logos or patterns, regardless of their complexity.

It is capable of automating, simplifying and storing cutting jobs, including generating missing data and information, as well as recording them and associating them with specific pieces in a fashion collection if necessary, and can now be complemented by FKgroup’s ARC – augmented reality camera – technology.

ARC combines AI, cameras, CAD, nesting and CAM to enable an operator to work in augmented reality in setting up the most precise possible cutting of panels and patterns.

It further makes the automatic positioning of parts possible by video on a real drawing – not a simulation – and the generation of any missing information, such as reference and meeting points.

ARC technology enables cutting systems to avoid the precision errors that transferring to paper entails, offering unprecedented accuracy and significantly reducing cutting times.

Robotics

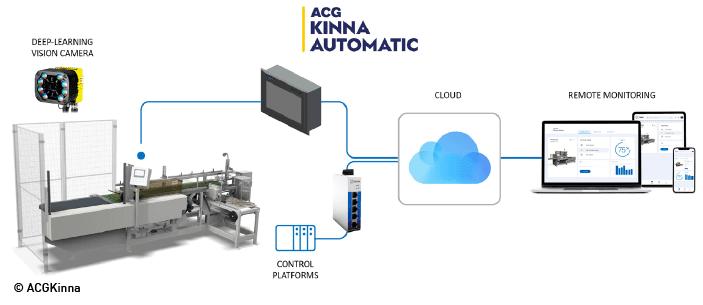

ACG Kinna, also headquartered in Sweden, drew considerable crowds to demonstrations of its robotic pillow filling system at ITMA 2023.

With the ability to fill and finish some 3,840 pillows per eight-hour shift, automated units cover the entire process – from the opening and weighing of the fibre to the filling of the product and on to the sewing and packing processes.

The system has been further developed to include new features including an integrated marking solution which allows the customer to print QR codes, batch numbers and dates on the pillows’ labels, and a unique software for automatically detecting pre-programmed faults.