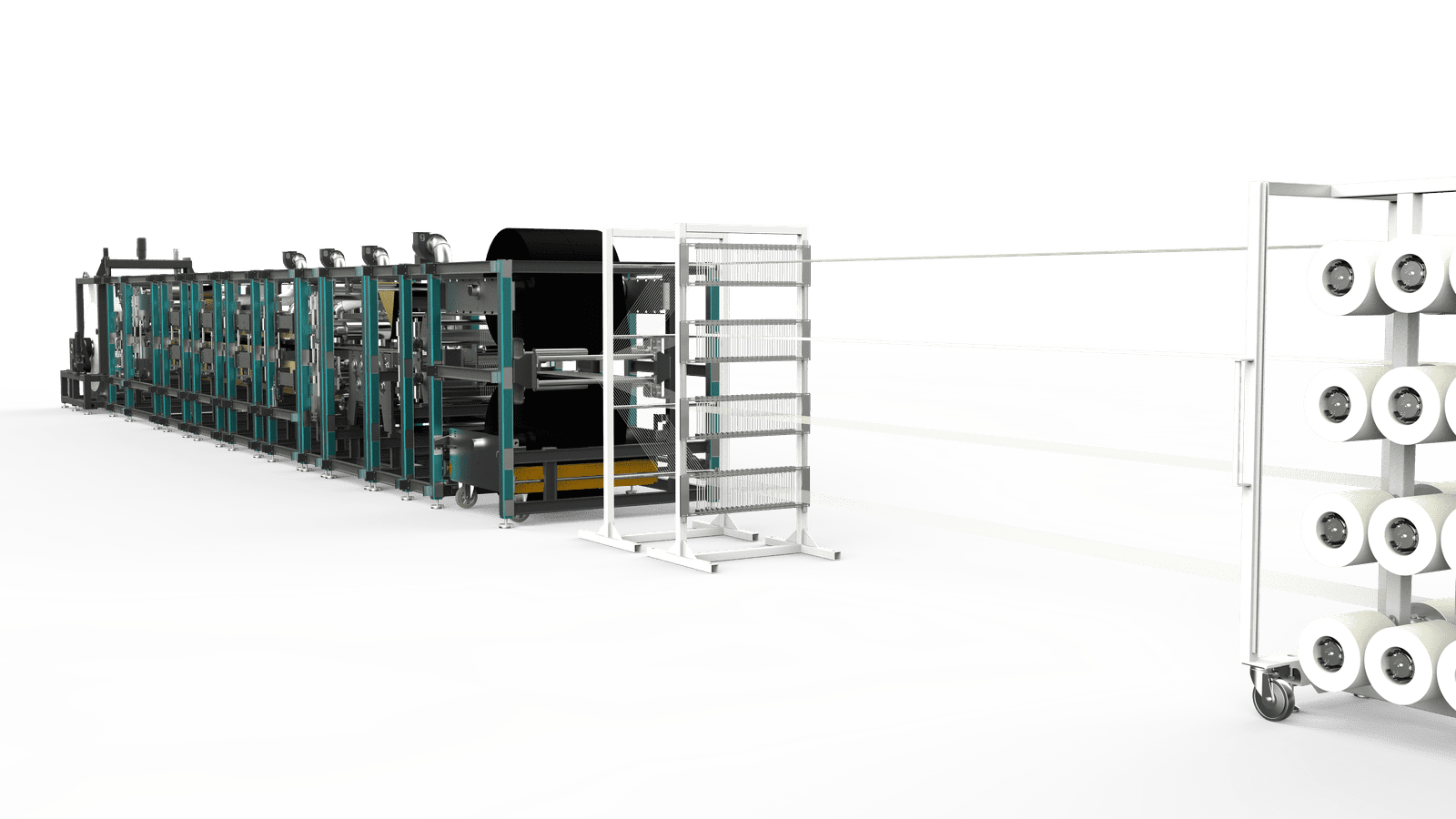

KARL MAYER Technische Textilien GmbH is continuing to develop into a systems supplier for non-crimped fabrics (NCFs) and is launching a new line for producing thermoplastic unidirectional tapes (UD tapes). The company is already known for its multiaxial warp knitting machines and its fibre spreading unit. This newcomer, SIM.PLY, combines a completely revised spreading module with well-thought-out impregnation technology in a continuous, efficient processing sequence. The seamless interface guarantees a consistently high spreading quality.

With their high quality and precise alignment of the continuous fibres, the tapes are ideal for use in highly stressed, fibre-reinforced, lightweight structures. The thermoplastic matrix also allows for effective processing, enabling mass production to be carried out. The SIM.PLY, with its high production speed and ability to produce tapes in a broad range of widths, is also suitable for mass production. Not only the new machine will be presented at ITMA, but also one of the products produced on it, together with the sequences for producing a structural component for the automobile sector.

In the „Future of Textiles“ area, the visitors will have the opportunity to see very promising applications for the textiles manufactured on the machines made by KARL MAYER Technische Textilien. The focus here is on the issue of concrete components reinforced with carbon or glass fibre NCFs rather than steel. By using textile concrete, it is possible to save up to 70% of the concrete and, as a result, CO2 emissions, energy and component weight can all be reduced. Other promising applications of technical warp-knitted textiles in the construction sector include cost-effective, flexible, stable roofing materials and bitumen roofing felts, special plaster grids that increase the cracking resistance in the plaster, and self-adhesive tapes for repairing any cracks and holes that do occur.

Besides, an innovative solution for personal protection equipment will also be showcased: a new bulletproof vest made from an aramid NCF, that is both effective and comfortable to wear. The functional textile was produced on a multiaxial warp-knitting machine, type COP MAX 5 with online spreading process.

More about SIM.PLY:

https://www.karlmayer.com/en/simply/