Shyam Barhanpurkar, Dr Kavita Sharma

Department of Textile Technology,&

Department of foreignsic science

Shri Vaishanv Vidhyapeeth Vishva vidhyalaye Indore

ABSTRACT

This paper throws a light on enhancing the dyeing & finishing viabilities of textile materials made out of Polyester, (Polyethylene Terephathalate) fibres as this fibre is highly hydrophobic in nature so it is very difficult to dye. Also it has got a very high Tenacity, so it has a wide area of applications in apparel as well as other industrial and home furnishing textiles. Therefore, an attempt has been made to improve the texture, dyeability and finishing parameters of Polyester textile material by plasma technology.

Plasma technologies present an environmentally-friendly and versatile way of treating textile materials in order to enhance a variety of properties such as wettability, liquid repellency, dyeability and coating adhesion. Recent advances made in commercially viable plasma systems have greatly increased the potential of using plasma technology in industrial textile finishing.

In order to increase the hydrophilicity, soil resistance and to improve dyeability, PET fabrics are treated in low-temperature plasmas. Fabrics are directly treated in acrylic acid, water, air, nascent oxygen and argon plasma. The plasma conditions are changed to control the extent of plasma surface modification. Wettability, soil resistance and dyeability of PET fabrics are significantly improved by this method.

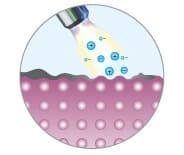

Plasma can be defined as a partially or wholly ionized gas with a roughly equal number of positively and negatively charged particles. it is a form of matter that has higher energy than the corresponding solid, liquid and gas form. However the energy that is found in solids, liquids and gases is largely carried in the form of kinetic energy – or heat. But in plasma the energy is also due to electrons being split from the atomic nucleus creating ions and free electrons. This means that plasma can carry a lot of energy and is highly reactive, but not necessarily hot. Plasma systems employ the beam of ions and free electrons to clean and activate surfaces without burning them.

Key words:Hydrofobic,Ionised gas,wettability, soil resistance

TYPES OF PLASMA:

There are two types of plasma –

- high temperature

- Low temperature.

HIGH TEMPERATURE PLASMA:

Lightning is naturally occurring high temperature plasma. This type of plasma can be artificially generated using a high voltage, high temperature arc, which is the basis for the corona discharge process and for the plasma torch used to vaporize and redeposit metals.

LOW TEMPERATURE PLASMA:

Low temperature plasmas are ionized gases generated at pressures between 0.1 and 2 torr. These types of plasmas work within a vacuum chamber where atmospheric gases have been evacuated typically below 0.1 torr. Low pressure allows for a relatively long free path of accelerated electrons and ions. Since the ions and neutral particles are at or near ambient temperatures and the long free path of electrons, which are at high temperature or electron volt levels, have relatively few collisions with molecules at this pressure the reaction remains at low temperature.

MECHANISM OF PLASMA: As our focus is on enhancing the dyeing & finishing viabilities of textile materials made out of Polyester, (Polyethylene Terephathalate) fibres as it is very difficult to dye, due to its hydrophobicity. Therefore, a key step required for effective dyeing and printing is to wet the polyester material. Since polyester being highly hydrophobic in nature, when water droplets are poured on the surface of polyester fabric, it forms beads and rolls down. Plasma technology promotes wettability by first cleaning the surface to remove contaminants, and then it increases surface energy by changing its structure.

Cleaning of surface by plasma Plasma the beam is created from the air by a pulsed current that excites the molecules. The resulting ions and free electrons then remove static electricity and dust, as well as vaporize contaminants, including waxes and silicone residues.

How plasma makes materials wettable: Many liquids are self-loving, so they do not spread out on a surface unless their energy is similarly high. The liquid can be visualized as having only Velcro-like loops, so in order to spread out; the surface needs to have a lot of hooks. Then the loops can attach to the hooks & these hooks can then bond firmly to paint, glue and ink. Plasma can improve the strength of bonding by a hundredfold.Water particularly self-love so paints, glues and inks that are water-based are incompatible with low-energy materials, including polymers commonly used in manufacturing.

Water has a high surface energy of 72 dynes/cm so when it meets a low-energy material like polypropylene (PP) that has a surface energy of below 28 dynes/cm the water will not be attracted and it will bead. When the polypropylene is treated with plasma its energy can be increased to over 72 dynes/cm, at which point the water will wet it completely.

It can be extremely useful to make materials wettable because then they can be bonded, printed or painted a lot more easily and without using organic solvents that are damaging to the environment.

TREATMENT OF PLASMA ON POLYESTER MATERIAL:

Plasma processes have been developed to attain a variety of specific surface properties. Here are some examples.

- Surface Cleaning – Oxygen plasma treatment is a safe and environmentally friendly cleaning method. A wide variety of industries utilize gas plasma treatment to remove organic surface contamination from polyester materials that require critical cleaning. The active species in the oxygen combined with UV energy creates a chemical reaction with the surface contaminants, resulting in their volatilization and removal from the reaction chamber. Applications include cleaning of circuit boards for improved wire bonding, removal of organic contamination from glass slides and flat panels, cleaning of medical devices etc.

- Adhesion promotion – Improving adhesion between two surfaces is a common application. Good adhesion requires strong interfacial forces via chemical compatibility and chemical bonding. Plasma surface treatment can also assist in creating chemically active functional groups such as amine, carbonyl, hydroxyl and carboxyl groups, to improve interfacial adhesion of polyester fabric. Plasma is also used to improve bondability on substrates such as glass, polymers, ceramics and various metals. Common applications include pretreatment for medical catheters, syringe components, dialysis pump parts and plastic films for drug bags.

- Controlling surface energies – Plasma processing can also be used to tailor surface energies. Hydrophilic and hydrophobic surfaces can be created on polymers through interaction with gas plasma. Using oxygen to create hydroxyl functionality increases the wettability of a polyester surface. Similarly, surfaces can be specifically engineered to modify protein binding and improve blood compatibility. Common applications include tissue culture wares, filtration or separation media and contact lenses.

- Enhancing performance – Surface cross linking is often used to enhance the performance of polymers of polyester materials. The activity of the plasma creates a higher cross linking density within the material to depths of a few thousand angstroms. The resulting increase in hardness and chemical resistance can enhance performance in many applications. Some applications are: Silicone rubber components treated in inert gas plasma can be modified to form a hard “skin” on the surface, By using a plasma immobilization process precoated molecules can be directly crosslinked onto polymer surfaces

DYEING OF POLYESTER FIBRE:

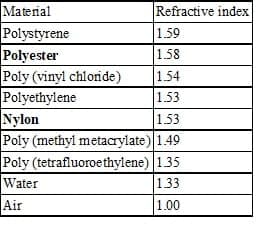

The refractive index of polyester fiber is higher than most other synthetic fibers. Then dyed polyester looks paler than nylon even though the same amount of dye exists in the fiber due to the diffused reflection on the surface of the fiber.

The table shows the refractive index of several polymers.

Improvement of the apparent depth of dyed polyester is implemented in three ways;

- modification of fiber,

- selection of dyes

- application of an auxiliary (finish) for deep dyeing.

- Use of modified (deep dyeing) fiber

The following fibers are developed and commercialized and these are effective for obtaining deep shades.

- Giving ruggedness (ultra-micro craters) on the surface of fiber to control the surface reflectance of light.

(1) Chemical erosion by weight reduction treatment

(2) Physical etching by plasma treatment

- Controlling the orientation of polymer to increase the dyeability

- Using thick yarn with low Young’s modulus

- Selection of dyes for deep dyeing

Conventional dark shades are designed to give average depth of dark shades with practical fastness and low cost, because for these dyes satisfaction of economic needs is the most important factor. For deep full shades the selection should be made, not from these cheap dyes, but from the specialized dyes.

- Dyes with excellent build up; the components should be examined to see whether the highest build up can be attained. Equalized dyes for full dark shade.

- Dyes with absorption in long wavelengths in visual light; in conventional black dyes, navy blues based on azo chromophore are employed, which can give practical blacks. But in this case, the absorption of area of 650-700nm is small, and this area should be covered by greenish blue to obtain deep full blacks.

Main dye producers have developed such dyes, but they are rather expensive.

- Finishing with auxiliaries:

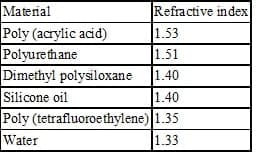

In finishing process of dyed polyester material, for example a shade of dye of black which looks wet like a deep full black, which is called “wet crow black”. This phenomenon comes from the low refractive index of water (1.33), and is applied in a technology for making deep full blacks. A permanent coating of polymer with a low refractive index on the polyester fiber can give deep full blacks.

Examples of polymer with low refractive indexes are shown in the following table.

Polyurethane, siloxane, or fluorocarbon based chemicals are commercialized as auxiliaries (finishes) for deep full blacks. These finishes are a mixture of several components to attain best performance. An alternative approach is to cover the surface of fiber with rugged film.

The finishing process using those chemicals is mainly carried out by padding.

The level of deep full black on regular polyester obtained by specialized black dye is around 12 by L value, and further improvement is attained by those after treatments to 9.6-10.5 by L value.

Machine Related Plasma Processing

FINISHING OF POLYESTER FABRIC:

Most of the problems that arise when polyester fabrics are treated with plasma do not apply when the surface has to be oxidized in the plasma for example to create polar and reactive functional groups. In that case the background pressure in the reactor is not so important and also the water from the webs can be utilized in the treatment. The only real danger is an over treatment. In a prolonged plasma exposure, polymers form low molecular weight substances which can deteriorate the surface properties, can be washed off and expose a surface which is treated to a lower extent.

More sophisticated treatments have a much narrower range of treatment conditions and need much more care in process control. The hydrophobation in fluorocarbon plasma is an example for such a type of treatment.

TYPES OF FINISHE

1.Water repellent polyester fabric

A fluorocarbon plasma treatment can reduce the soaking of fabrics in a similar way like a traditional impregnation. However, in contrast to the wet treatment, the fabric retains its flexibility after the plasma treatment.

2. Wettability improvement

In oxygen plasma the number of functional groups at the surface can be increased. The increased polarity makes the material more wettable which can be used to improve dying and sizing.

In the table we summarized examples where various polyester fabrics were oxidized. The effect of the treatment was checked by a water rise test, i.e. a strip of the fabric was put into water end the time was measured until the water rise up 3 cm.

The test was repeated a certain time after the treatment. The results show a good stability of the treatment.

Water rise time (s):

3. Adhesion improvement in laminates and composites

In oxygen plasma the number of functional groups at the surface can be increased which can improve the adhesion to other material. The results are stronger laminates and better composite materials.

As an example, there are results of lamination tests with polyester fabric. (PES)

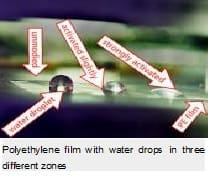

The shape of the water drops on the PE film is determined by a few layers of atoms at the surface. It is a region which is about 1 nm thick. Altering the chemistry in such a shallow layer can considerably improve the material’s properties.

The activation of a surface means that it is oxidized in order to form functional groups which can interact with other substance, be it water, paint or an adhesive. The use of highly energetic means as electrical discharges for surface activation results in a complex mixture of functional groups which can only be tuned in a rather narrow range.

4. Coat-finishing polyester fabrics,

The present invention relates to a new method of coat-finishing polyester fabrics to produce anti-migration properties.

This method is comprised of two steps as follows.

- A uniform resin composition is formed by adding a cyclic compound of a non-reductive, maltooligosaccharine, a cyclodextrin in which 6-8 units of glucose exists in α-1,4 glucoside-bonded form, to the coating resin composition.

- This uniform resin composition is coated on the fabric surface by known methods.

The coating effect is especially high in the case of 100% polyester fabrics dyed with disperse dyes. A coat-finishing method for polyester woven and knitted fabrics has been developed because of the excellent mechanical properties, dimensional stability, weather resistance, aesthetical properties and low prices of polyester fiber.

However, these coat-finished, woven and knitted polyester fabrics suffer from problems. For example, the problem of staining white or light color fabrics adjacent to the coat-finished fabrics exists, due to the migration of the coating layer during the processes of coat-finishing, sewing, handling, storage and use.

Dyeing of polyester fiber by disperse dyes can be summarized as a process of inserting dye into the polymer chain by physical affinity, without chemical bonding between the fiber and the dyestuff.

Since the disperse dye migrates easily, especially to the coating layer, the quality of goods is lost and the migration from fiber to coating layer during sewing, handling, storage and use and from the coating layer to fiber goods adjacent to the coated fabrics occurs easily and results in staining. To alleviate the above-mentioned migration problem of coat-finished fabrics composed of polyester fiber, a number of coating methods have been applied such as:-

- Preventing migration by using a special process of wetting with a tannin compound before or after the coat-finishing process.

- Migration may be prevented by using N-alkoxydimethylated polyamide as a coating resin.

- there is a method for formation of a special coating layer which prevents migration by coating a highly hydrophilic amino acid resin on an existing coating layer

- Performing the coat-finishing process after the dyed fabric is treated with a low temperature plasma at constant pressure.

However, the above mentioned processes suffer from a number of problems such as,

(a) It is expensive to add new process steps to the coat-finishing process or to localize a kind of coating resin and to mix the resin with an inorganic materials.

(b) The quality of goods is lost by decreasing the drapeability of coated fabrics.

(c) The degree of confidence in production is decreased since the process of anti-migration coating is complicated and great care must be taken in the mixing process of the resin and the coat-finishing process.

But the basic concept to obtain good anti-migration properties is by coupling dyestuffs with a tannin compound to slow down the mobility of the dyestuffs in coating layer. However, it is expensive to treat the fabric with synthetic tannin and tannic acid since a special wetting process is necessary and the productivity is lowered by adding this new process step.

Moreover, the wetting treatment with tannin compound suggested in the above disclosure is a known method which is generally used for the improvement of color-fastness to washing of fiber goods dyed with acid-dyes, reactive dyes and partial basic dyes. But this treatment is known to be not effective or only slightly so in the case of disperse dyes.

- Plasma technology is very much economical for dyeing of any synthetic fiber by high temperature high pressure dyeing machine.

- Dye absobtion capasity depends upon the dye panetration effect which will come with the hedrofillic carecter of the plasma treated polyster. The good result of dyeing will depend upon the correct application of Plasma technology.

- The high panetration of the plasma beam on the fabric surface can alter the result of dyeing , means the cause of dyeing shade varriation , patchyness, deeper-lighter shades.

- Time duration of plasma electon flowing on the surface of the material should be set according to the fiber bonding capasity of the material, so, this depend upon the inter fiber molecular structure , surface charecteristics and fiber density.

- In high temprature plasma process always the low lavel of pressure of electron flowing should be maintained to control the quality of the material. Thus in further process of dyeing timing can be minimised.

- In finishing of textile polyester material the thickener cost is redused because at the time of plasma treatment the material will be more porous to attract the bonds of thickner.

- In plasma dyeing and finishing processes the abrasion resistance, pilling tendencies, tearing strength and crease recovery properties of fabrics are improved.

References:-

[1] L. Tonks, “The birth of ‘plasma'” Amer. J. Phys., vol. 35, pp. 857-858, 1967.

[2] Letter from H. M. Mott-Smith to A. M. Bueche, Apr. 20, 1967 (on file at Communications Operation, General Electric R&D Center, Schenectady, NY).

[3] S. C. Brown, “A short history of gaseous electronics,” in Gaseous Electronics, vol. 1, M. N. Hirsh and H. J. Oskam, Eds. New York: Academic, 1978, pp. 1-18.

[4] I. Langmuir, “Oscillations in ionized gases,” Proc. Nat. Acad. Sci. U.S., vol. 14, p. 628, 1928; also available in The Collected Works of Irving Langmuir, vol. 5, C. G. Suits, Ed. New York: Pergamon, 1961, pp. 111-120.

[5] Maximov A.I., Titov V.A. Theoretical problems of plasma-chemical reactors. Tekstilnaja khimija (Textile Chemistry), No 2, (4), (1993), P.36-45.[6] Maltseva S.V., Ivanov A.N., Maximov A.I. Several effects of linen fabrics plasma treatment. Tekstilnaja khimija (Textile Chemistry), No 1(3), (1993), P.76-79.[7] Zakharov A.G., Maximov A.I., Koksharov S.A. The prospects of physical effect applications under textile material treatment. Book of Papers, 17th IFATCC Congress.

[8] Handbook of Plasma Technology for Chemical Dyeing and Finishing.

[9] Chemical Technology of Fibrous Materials by F. Sadov, M. Korchagin, A. Matetsky, MIR Publishers MOSCOW.