Cellulose fibre has become a trend in the development of textile. Pineapple leaf fibre (PALF) is a natural cellulosic fibre collected from pineapple leaves. Every year tones of PALF are being produced but very small portions are being used. This is due to lack of technology suitable for fibre utilization, as well as grower’s ignorance of the possible uses of fibres, which can generate them extra income. The pineapple leaf is currently being wasted in most regions that grow this plant, with only the fruit itself being utilized. In recent decades, pineapple has become a crop of great importance for the north-east of Brazil, with respect to the regional economy [IBGE, 2004]. However, after harvesting, the fruit’s leaves (rich in fibre) are placed for pasture for cattle, or in most cases left to rot.

Pina is a traditional Philippine fibre made from pineapple leaves. Pineapples were widely cultivated in the Philippines since the 17th century for weaving lustrous lace-like luxury textiles known as nipis fabric. The name Pina ia a Spanish word, meaning Pineapple. The fibres derived from pineapple leaves are long, strong, white, silky with one of the best fineness indexes among vegetal fibres, which make them suitable for many industrial applications.

Certain cultivars are grown especially for fibre production and to give the plant maximum vitality, their young fruits are removed. For fibre extraction ‘Perolera’ is an ideal cultivar because its leaves are long, wide and rigid. Resembling grass cloth, Chinese people in Kwantgung Province and on the island of Hainan weave the fibre into coarse textiles. Long ago in Malacca and Borneo, it was used for threads. In India, the thread was formerly used in the Celebes and now it is prized by shoemakers. In West Africa, it is used to make capes and caps worn by tribal chiefs and for stringing jewels. For making fine casting nets the people of Guam hand-twist the fibre. The fibre is also used for wrapping or sewing cigars. Pina cloth is highly esteemed which is made on the island of Panay in the Philippines and in Taiwan.

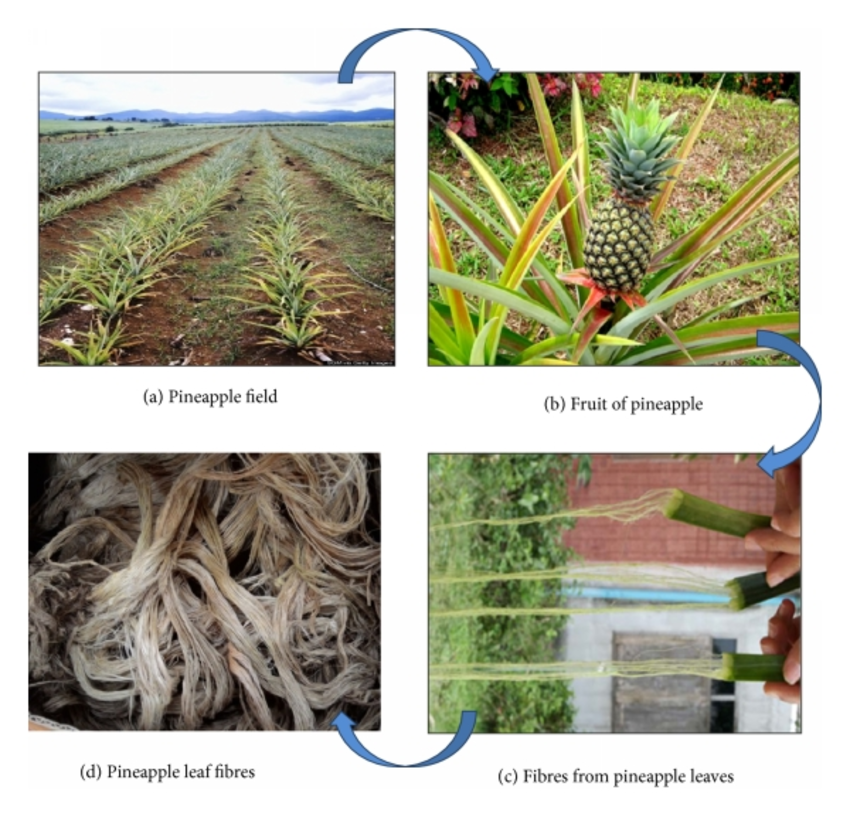

PRODUCTION OF PINEAPPLE FIBRE

Since Pina is from a leaf, after the harvest of the pineapple fruit the plant leaf is first separated from the plant. Then the fibres are detached from the leaves by the hand scraping method (coconut husk are good for this). The bundle of cellulosic strands is then washed at a nearby river and then hung to dry. After waxing the strands to relieve any entanglements and whipping to release any final plant tissues, the leaf strands are then knotted one by one to create a continuous filament yarn as the abaca fibre which is a similar traditional method. Up to 15-18 pieces of white, creamy lustrous fibre, about 60 cm long each can be provided by a kilo of leaves and it easily retains dyes. Most leaf fibres are long and somewhat stiff. Researchers have developed some easy tools to extract fibre from pineapple leaves.

It’s worth noting that, during this process the fibre is split into two qualities: bastos, which is strong and coarse for making household items like rugs, etc and other quality called liniwan, which is very fine so suitable for weaving cloth.

Fibre from Pineapple leaves for long has been used by Philippine handicraft artisans to produce cloth. Among the other vegetal fibres, Pineapple fibre is considered to be more delicate in texture.

It is a painstaking process and involves up to 30 people from the beginning to the end of the process. By means of a broken plate or coconut shell fibres of the leaf are scrapped. Over 500 leaves per day can be extracted by a fast scraper, after which the fibres are washed and dried in the open air.

After which they are waxed to remove the entanglements and then the fibres are knotted and bind into yarns for the next process of weaving it in to fabric. For creating Barong Tagalog and other formal wear Pineapple fabrics are mainly used. Where a product with lightweight, but stiff and sheer fabric is needed, pineapple fabric is used. To create a textile fabric, it is sometimes combined with silk or polyester to create a textile fabric.

PROPERTIES OF PINEAPPLE FIBRE

The Pina fibre is softer, and has a high lustre, and is usually white or ivory in colour. The end fabric is easy to care, lightweight and similar to linen has an elegant appearance. Pineapple fibres are naturally glossy and have an ivory-white colour. This delicate and dreamy cloth is translucent, soft and fine with a high lustre. Pineapple silk is said to be the queen of Philippine fabrics and is considered as the Philippine elite’s fabric of choice.

In Philippine’s islands the Pina cloth is soft, durable and resistant to moisture. It is also used in making mats, bags, coarse grass cloth and for clothing. The fibres are bundles of many overlapping cellulosic cells and are much, stiffer and longer than cotton. The cells adhere by means of lignin cements.

As the pineapple leaf fibre fabric or the Pina fabric is lightweight but stiff, this sheer fabric can be used in any creative design. These fabrics, have many other qualities apart from environmental friendly.

- They have beautiful elegant appearance with natural shine, similar to that of linen.

- They are lightweight.

- They blend very efficiently with other fibres.

- They are very soft, even softer than hemp.

- They have better texture than silk.

- They can be washed and don’t need to be dry cleaned.

As the making process of Pina fabric is tedious, time consuming and labour intensive, it becomes quiet expensive. However, its price becomes immaterial when worn as one can feel the luxury of this exotic fabric. In fact, a garment of piña fabric is categorized as an heirloom garment.

In a project, pineapple, being a leaf fibre and due to its long length it was used in worsted spinning. Pineapple fibre was brought from South India. In the ratio of polyester/pineapple 80/20, it was blended with polyester tops. Then fabric was made for suiting purposes. The feel and look was very good. To create wonderful light, breezy fabrics, Pina fibre is often blended with cotton, abaca, and silk. It’s called pina seda or pina-silk, when woven with silk. For strength and sheerness Pina jusi is blended with jusi (abaca or silk) and is less expensive than 100% Pina.

Pineapple leaf fibre (PALF) which is rich in cellulose has the potential for polymer reinforcement.

Bleaching of pineapple fibre is done by Hydrogen peroxide at boil. As per requirement pineapple fibre is dyed using ME dyes at 60 degrees Celsius or HE dyes at 80 degrees Celsius. Vat dyes are used in cases where high fastness is required.

SPINNING PROCESS

The spinning of pineapple fibres on worsted system. It was carried out as follows.

- Blender.

- Carding.

- Combing.

- Mixing with polyester tops/wool tops. /viscose tops.

- Recombing.

- Gilling

- Roving.

- Ring frame

R&D department should start working on using pineapple fibres in synthetic/cotton spinning system. It will become a value added item. It will have good export potential.

USES OF PINEAPPLE FIBRE

Pineapple fibres, primarily used in hand weaving are divided into two groups- the linuan or fine fibres and bastos or coarse fibres. To make valuable items such as traditional Barong Tagalog, blouses for women , wedding attire for men , handkerchiefs, kimonos, panuelos, table linen, mats, fans, gowns, and other clothing, for hand weaving red Spanish or native variety of pina is mainly used. For development of Philippine Tropical Fabrics, smooth Cayenne or Formosa varieties are primarily used.

The Barong Tagalog and other formal wear that is common in the Philippines is majorly made from Pina fabrics. It is also used for other table linens, mats, other clothing items, bags, or anytime that a lightweight, but stiff and sheer fabric is needed.

Calado, a traditional style of hand embroidery is done on pina fabric to decorate it. An embroidered piña garment is known as pina calado. Vegetable dyes obtained from leaves and bark of various trees are used on these handwoven fabrics.Pina fibre is often blended with cotton, abaca, and silk to make amazing light and breezy fabrics.

Summary:

- Every year tones of Pineapple leaf fibre are being produced but very small portions are being used.

- Pinais a traditional Philippine fibre made from pineapple

- The name Pina ia a Spanish word, meaning Pineapple.

- The fibres derived from pineapple leaves are long, strong, white, silky with one of the best fineness indexes among vegetal fibres, which make them suitable for many industrial applications.

- The fibres are detached from the leaves by the hand scraping method (coconut husk are good for this).

- Fibre from Pineapple leaves for long has been used by Philippine handicraft artisans to produce cloth.

- Up to 15-18 pieces of white, creamy lustrous fibre, about 60 cm long each can be provided by a kilo of leaves and it easily retains dyes.

- The Pina fibre is softer, and has a high lustre, and is usually white or ivory in colour.

- As the making process of Pina fabric is tedious, time consuming and labour intensive, it becomes quiet expensive.

- Pineapple fibres, primarily used in hand weaving are divided into two groups- the linuan or fine fibres and bastos or coarse fibres.

References:

Clothing made from pineapple fiber. (2017, November 26). Retrieved August 05, 2020, from https://www.textiletoday.com.bd/clothing-made-pineapple-fiber/

Stephanie Steele Tuesday. (2019, June 04). What is pineapple fibre and how do you make textiles from it? Retrieved August 05, 2020, from https://www.the-sustainable-fashion-collective.com/2019/06/04/what-is-pineapple-fibre-and-how-do-you-make-textiles-from-it

Fibre. (n.d.). Retrieved August 05, 2020, from http://prsvkm.kau.in/book/fibre

Piña. (2020, May 07). Retrieved August 05, 2020, from https://en.wikipedia.org/wiki/Pi%C3%B1a

Ismoilov, K., Chauhan, S., Yang, M., & Heng, Q. (2019, September 10). Spinning System for Pineapple Leaf Fiber via Cotton Spinning System by Solo and Binary Blending and Identifying Yarn Properties. Retrieved August 05, 2020, from https://www.scirp.org/journal/paperinformation.aspx?paperid=95321

(n.d.). Retrieved August 05, 2020, from https://www.scirp.org/(S(351jmbntvnsjt1aadkposzje))/reference/ReferencesPapers.aspx?ReferenceID=2592860