BY NCFA TEAM

1. Botanical Information

The botanical name of pineapple is Ananas comosus. It is considered a herbaceous, tropical, and monocot perennial plant. The pineapple (Ananas comosus: Bromeliaceae) is one of the most popular tropical fruits. Pineapple in English (or piña in Spanish) comes from the fruit’s similarity to a pinecone. Ananas comes from anana, the Tupi word for the fruit, meaning “excellent fruit”. Comosus means tufted and refers to the stem of the fruit. The pineapple is a herbaceous perennial which grows to 1.0 to 1.5 metres tall, although sometimes it can be taller. In appearance, the plant itself has a short, stocky stem with tough, waxy leaves. The stem at its centre is about 25–50 cm long. A mature pineapple plant has about 60–80 leaves, each being sword-shaped. An embroidered Pina garment is called a ‘Pina calado’.

2. Agro Climatic Conditions for Cultivation

2.1 Climate

Pineapple grows in warm and humid climates. The optimum temperature is from 15° to 32°C for normal growth. High temperature over 35°C is unfavourable for the development of fruits, especially if the relative humidity is low. Exposure of the fruits to strong sunshine leads to sun scalding. It can be grown at an elevation of 1,100 m above sea level, if these places are free from frost, have a relatively high atmospheric humidity and an annual rainfall of 760-1,000 mm.

2.2 Soil

Pineapple is grown on various types of soils including very poor soils. The flavour and quality of fruit grown on light soils are observed to be superior. However, the sandy and loamy soils rich in humus and the laterite soils on the hill slopes in South India are suitable for its cultivation. The plant is susceptible to soil being waterlogged. Therefore, care should be taken to ensure proper drainage. It prefers soils having a range of 5.0-6.0 pH values.

2.3 Irrigation

Pineapple needs light and frequent irrigation due to its shallow root system. Irrigation is given only during dry months from January till the onset of monsoon. During summer months, pineapple may be irrigated wherever possible at 0.6 IW/ CPE ratio (50 mm depth of water) for good fruit size and high yield. It requires five or six irrigations during dry months at an interval of about 20 days. Mulching the crop with dry leaves at 6 t/ha will help to conserve moisture. If there is no irrigation facility, the crop should be scheduled for harvest before the summer months (before March). However, supplementing with green manure is preferred.

3. Area of Production

The important pineapple-growing countries of the world are the Hawaiian Islands, China, Philippines, Malaysia, Thailand, Brazil, Ghana, Kenya, Mexico, Taiwan, South Africa, Australia, Puerto Rico and India. In India, it is grown in Karnataka, Meghalaya, West Bengal, Kerala, Assam, Manipur, Tripura, Arunachal Pradesh, Mizoram, and Nagaland. It is also cultivated in limited areas in the coastal belt of Tamil Nadu, Goa, and Odisha. India is in the sixth position with a share of about 8 % of the world’s production of pineapples. The total area under pineapple cultivation in India was 89000 hectares with a production of about 1415000 t and productivity of 15.9 t/ha during 2010-11.

India exports pineapple mainly to Nepal, Maldives, the United Arab Emirates, Saudi Arabia, Kazakhstan, Oman, Bahrain, Bangladesh, Zambia, Pakistan, and Qatar. ‘Kew’ and ‘Mauritius’ are the two varieties of pineapple grown in India. It is grown in Karnataka, Meghalaya, West Bengal, Kerala, Assam, Manipur, Tripura, Arunachal Pradesh, Mizoram, and Nagaland. It is also cultivated in limited areas in the coastal belt of Tamil Nadu, Goa and Orissa. Though Assam has the largest area under pineapple, West Bengal is the largest producer. Karnataka, West Bengal and Bihar are the three states reporting high productivity. Overall, Indian productivity of 15.9 t/ha is poor compared with the world average of 22.58 t/ha.

4. Features of Pineapple Leaf Fibres

Pineapple fibres are a by-product of pineapple farming and have so far ended up in waste. Yet they have enormous potential for use in a sustainable fashion. Pineapple leaf fibre (PALF), also known as Piña, is hence, a natural and sustainable textile material that is obtained from the leaves of the pineapple plant. Piña fibre is a plant fibre commonly found in the Philippines. The pineapple fibre is soft, translucent, white, or ivory and has lustre. It has an elegant appearance similar to linen and is lightweight and easy to care for. Pineapple silk is considered the queen of Philippine fabrics. It is durable and resistant to moisture. The yield of fibre is 2.5 to 3.3% of the weight of green leaves. It can blend efficiently with any other fabrics. It can be washed and doesn’t need to be dry cleaned. It is 10 times coarser than cotton and the fibre has a higher dye absorption tendency due to its higher moisture regain. It can also be dyed with basic dyes at room temperature due to the presence of lignin and hemicellulose, which are more than 15% amorphous in character with acidic nature. It is very hygroscopic. Coloured white with a sleek appearance. It has a high cellulose content. Shiny as silk. It has a low microfibrillar angle and is moderate in length. Fibre bundle strength decreases by 50% when wet. It is sweat-absorbent and breathable fibre. It is hard and has no wrinkling properties. It has good antibacterial and deodorization performances. It has high insulation power and high absorbency.

5. Mechanical Characteristics of Pineapple Leaf Fibre

5.1 Strength and Durability

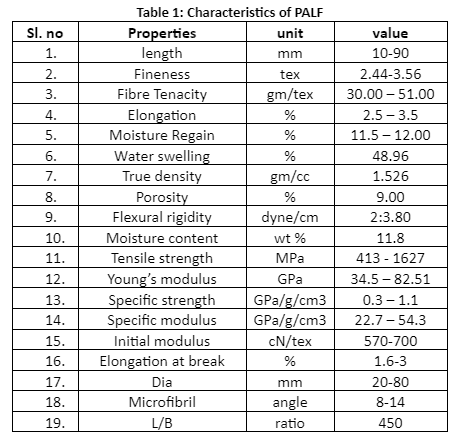

Piña fibre is a strong and durable material, which means that it can withstand wear and tear over time. It is stronger than cotton and has a similar tensile strength to silk. Table 1 gives the gist of the important characteristics of pineapple leaf fibres.

Table 1: Characteristics of PALF

5.2 Lustrous Appearance

Pineapple leaf fibre has a shiny, silky texture that gives it a lustrous appearance. This makes it an ideal material for creating garments and accessories with a luxurious look and feel.

5.3 Softness

Despite its strength, Piña fibre is also soft and comfortable to wear. It is not itchy or scratchy like some other natural fibres, making it a great choice for people with sensitive skin.

5.4 Eco-friendly

PALF is a sustainable and eco-friendly material, as it is made from the leaves of the pineapple plant, which are a byproduct of the fruit industry. This means that no additional resources are required to produce the fibre, and it helps to reduce waste.

5.5 Breathable

It is naturally breathable, which means that it allows air to circulate through the fabric. This makes it a great choice for warm-weather clothing, as it helps to keep the wearer cool and comfortable.

5.6 Absorbent

Pineapple fibre is also absorbent, which means that it can wick moisture away from the skin. This makes it a great choice for activewear and other garments that need to be moisture-wicking.

6. Chemical Composition of Pineapple Leaf Fibre

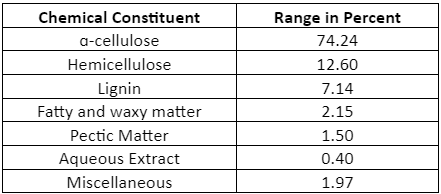

The Chemical composition of the PALF is given in Table 2. It may be noted that the major constituent is ꭤ-cellulose with the spread of other minor constituents.

Table 2: Chemical Composition of PALF

7. Production Methods of Pineapple Leaf Fibre:

7.1 Scraping a pineapple leaf to reveal the fibres.

Since piña is from a leaf, the leaf has firstly to be cut from the plant. Then the fibre is pulled or split away from the leaf. Most leaf fibres are long and somewhat stiff. Pineapple leaf fibre is produced through a process called decortication, which involves separating the long fibres from the leaves of the pineapple plant. The leaves are first harvested, cleaned, and sorted to remove impurities. They are then processed through a scutcher to separate the fibres, which are washed, dried, and combed to create a uniform texture. The resulting fibre can then be spun into yarn using either hand or machine spinning methods. Finally, the fibre can be bleached and dyed to create a range of colours and finishes depending on the desired application. While the production of Piña fibre is still largely done by hand, advances in technology have made it possible to automate some of the steps to increase efficiency and reduce costs.

7.2 Extraction Process

Various stages of processing to extract the fibres from the leaf are described below

7.2a Harvesting and Retting

The process of harvesting begins with the collection of pineapple leaves after the fruit is harvested. This ensures that every part of the pineapple plant is utilised thereby minimising the bio-waste disposal. Under natural conditions, pineapple comes to harvest from May-August. With a slight colour change at the base of the developing fruit, it could be harvested for canning purposes.

The outer long leaves are preferred for fibre. In the manual process, they are first decorticated by beating, rasping and stripping, and then left to rest in water to which chemicals may be added to accelerate the activity of the microorganisms which digest the unwanted tissues and separate the fibres. Retting time has been reduced from 5 days to 26 hours. The retted material is washed to clean, dried in the sun and combed. In mechanical processing, the same machine can be used to extract the fibre from sisal. Estimating 22 leaves/kg, 22,000 leaves would constitute one tonne and would yield 22-27 kg of fibre.

7.2b Fibre Extraction

The leaves undergo a mechanical extraction process, where fibres are separated from the leaf pulp. The fibres are then washed to remove impurities and prepared for the subsequent steps.

7.2c Degumming and Drying

The extracted fibres undergo a degumming process to remove any remaining non-cellulosic components. Afterwards, the fibres are dried under sun/shade, resulting in a spinnable material.

7.2d Types of Pineapple Fibres

- Linuan: referred to as fine fibres.

- Bastos: referred to as coarse fibre

- Typical Uses of PALF

- The pineapple fibres can be used in wide applications from apparel to technical textiles.

- Used in industrial applications like tyres and conveyor belts and can be used in the paper manufacturing industry.

- The pineapple fabric is used to make upholstery and furnishing.

- It is used for making table linens, bags, mats, and other clothing items.

- It is used for making a thin and transparent embroidered garment known as barong Tagalog which is worn over a shirt and other formal wear in the Philippines.

- It is used for making wedding attire for men, blouses for women, kimonos, panuelos, gowns, and handkerchiefs.

- Sports items, baggage, automobiles, cabinets, and mats. Surface-modified PALF is introduced for making machinery parts like belt cords, conveyor belt cords, transmission cloth, and airbag tying cords.

- It is generally used in making threads for textile fabrics.

- It can be suitable for various other applications such as cosmetics, medicine, and biopolymers coating for chemicals.

- It is used to reinforce the corrugated roofing sheets.

- Clothing: Piña fibre is often used to create clothing, including dresses, shirts, skirts, and jackets. The lustrous and soft texture of the fibre makes it ideal for creating high-end fashion garments.

- Accessories: Pineapple fibre is also used to create accessories such as bags, hats, and shoes. The durability of the fibre makes it a great choice for accessories that need to withstand daily wear and tear.

- Home textiles: PALF is also used in the production of home textiles such as curtains, tablecloths, and upholstery fabrics. The shiny and lustrous appearance of the fibre makes it a popular choice for creating elegant and stylish home decor items.

- Paper: Piña fibre is also used in the production of high-quality paper, which is commonly used in the printing of banknotes, certificates, and other important documents.

- Industrial applications: Pineapple leaf fibre can also be used in industrial applications, such as reinforcement in composites or as a reinforcing agent in rubber products.

- Automotive industry: It can be used in the automotive industry to create lightweight and durable parts for cars and trucks. The fibre can be combined with a resin matrix to create composite materials that are strong and lightweight.

- Construction industry: Pineapple fibre can also be used in the construction industry to create composite materials for building structures. The fibre can be combined with a polymer matrix to create composite panels that are strong, lightweight, and durable.

- Aerospace industry: PALF can be used in the aerospace industry to create lightweight and strong parts for aircraft and spacecraft. The fibre can be combined with a resin matrix to create composite materials that are strong and lightweight, which can help to reduce the weight of the aircraft or spacecraft.

Sources

https://www.fabricsight.com/blogs/posts/embracing-sustainability-pineapple-leaf-fiber-in-fashion

https://www.textilecoach.net/post/pineapple-fiber-pineapple-leaf-fibre-pale

https://textileengineering.net/pineapple-leaf-fibre-properties-production