Swati V. Chavan

K. T. E Society’s Textile and Engineering Institute, Ichalkaranji, Maharashtra, India

Abstract:

Nonwoven fabrics are the simplest textile fabrics. Considering the environmental aspect now a days nonwoven fabrics are getting preferred in the packaging industry as well for variety of applications instead of polyethylene material. This study consists of printing of needle punched non-woven viscose rayon fabrics considering the ease of application of pigments for coloration of textile substrates. The viscose non-woven fabrics were printed with pigment using binder by varying the pigment to binder ratio and polymerizing was carried out at two different temperatures. The prints were tested for colour yield and rubbing fastness properties (dry & wet). It was observed that with increasing the concentration of binders the depth of the pigment prints gets increased also the fastness properties get improved.

Key words: Nonwoven fabric, Packaging, Viscose Rayon, Pigment, Binder, Rubbing fastness.

- Introduction:

Nonwoven fabrics are the simplest textile fabrics. Its classic example is felt. The first well documented discovery of felt dates back 3500-3000 BC. It was made from hairs of various animals. The term “Nonwoven fabrics” was applied to new modern techniques, which were totally based on new principles, by U.S.A. in 1965. “Non-woven fabrics” is being defined into different ways by different literatures; the term defined by “Textile oregano” in 1965 is as follows:

“Nonwoven fabrics are products made of parallel laid, cross laid or randomly laid webs bonded with application of adhesive or thermoplastic fibre under application of heat and pressure.”

Pigments are substance in particular forms. They are essentially, insoluble in the media into which they are incorporated, and are mechanically dispersing there in order to modify the colour and light scattering properties of such media.

In other words nonwoven fabric can be simply defined as a fabric those can be produced by a variety of processes other than weaving and knitting.

The nonwoven fabric properties depends on following particulars to an great extent,

- The choice of fibers.

- Technology which determines how the fibers are to be arranged.

- The bonding process and the bonding agent.

Fabric properties of nonwovens range from crisp to that soft-to-the –touch to harsh, impossible-to-tear to extremely weak. This leads to a wide range of end products such as nappies, filters, teabags, geotextiles, etc. some of which are durable and others are disposable.

The first stage in the manufacturing process of nonwoven fabrics is “production of web” and another is “bonding of web by using several methods”. Some of those (binding methods) are felting, adhesive bonding, thermal bonding, stitch bonding, needle punching, hydro-entanglement and spin laying.

1.1 Rayon: In the man-made fiber, rayon (viscose) has been the leader in bringing about changes in the industry and today finds practical use in a wide variety of fabrics. Nonwoven viscose rayon fabric can be used as an alternative to polyethylene based packaging materials, bags since it can be processed easily and available in variety of descriptions.

1.2 Printing: Printing improves the appearance and aesthetic value of the substrate. Dyes and pigments are generally used for printing textile substrate. Pigments are substance in particular forms. They are essentially, insoluble in the media into which they are incorporated, and are mechanically dispersed there in order to modify the color and light scattering properties of such media. Pigment printing on textile substrate offers prints with good economy and easy application conditions.

1.2.1 Pigment printing on Viscose Nonwoven fabric: Pigments are insoluble in water and do no affinity for the textile substrate. Pigment printing is most economical printing process which allows maximum output of goods because of the elimination of washing off and thereby reduces the effluent generation. It is popular due to quick sampling and high printing speeds.

1.3 BINDER

• Since pigments do not have affinity for textile substrate those are bound with textile substrate with the help of binder. Binder actually holds the pigment particles and sandwich it between fabric surface and its transparent three dimensional polymeric elastic film which is formed during polymerization at elevated temperature.

• In addition to binder another component is also added to the textile pigment printing paste and that is called fixer. Fixers are mostly urea formaldehyde pre-condensates which help in improving rubbing fastness of pigment by strengthening of binder cross links to hold pigment on the textile substrate.

2. Plan of work:

2.1 Material:- Viscose needle punched nonwoven fabric 80 gsm

2.2 Chemical:-Commercially available Red and Blue Pigment, Acrylic based Binder and synthetic thickener, Diammonium phosphate, Urea of L.R grade

2.3 Equipments:- Printing table, Wooden baby Screen 12”x12”, Mechanical stirrer of 3000 rpm, Laboratory stenter machine, Drier, Computer Colour matching system Macbeth Colour Eye-3000, Crock Meter

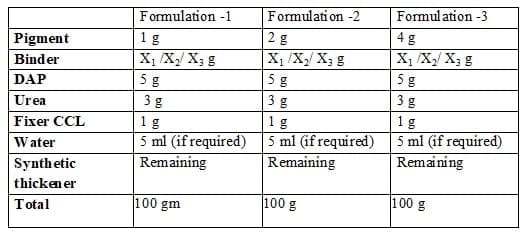

2.4 Print Recipe:- The pigment pastes were prepared by using following formulations.

X1 /X2/ X3 stands for varied Pigment to binder ratio as- 1:2, 1:3 and 1:5respectively.

2.5 Process Sequence :

Printing àDrying àPolymerization (at 140 and 1500C for 4 min)

2.6 Testing :

The colour strength (K/S values) of pigment prints was measured on Macbeth computer colour matching system and Rubbing fastness (dry and wet) of the prints was assessed on Crock meter.

3. Results and Discussion

3.1 Effect of binder to pigment ratio and temperature on colour strength of Red pigment:

Table number 1 indicates the effect of binder to pigment ratio and temperature on colour strength of Red pigment.

Table no.1

The results from table no 1 and Graph No. 1 indicate the effect of pigment to binder ratio and polymerization temperature on the colour yield of red pigment. The K/S value of 1% concentration of pigment for the pigment to binder ratio 1:2 is 7.52 and that of for 1:3 and 1:5 ratio are 7.81 and 7.97 at 1400C polymerization temperature. For the same concentration the K.S values at 1500C are 8.05, 8.62 and 8.77 respectively. Thus there is significant increase in the colour strength of red pigment with increasing binder concentration and polymerization temperature. This can be attributed to the fact that 1:5 ratio of pigment to binder shows higher colour yield where good cross linking of binder is achieved and prints are brighter.

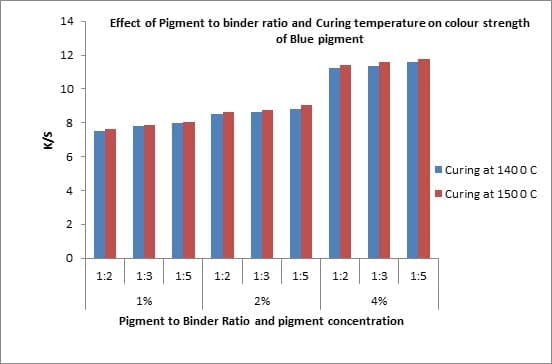

3.2 Effect of binder to pigment ratio and temperature on colour strength of Blue pigment:

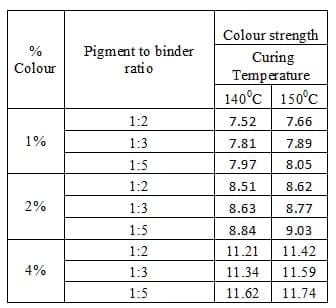

Table number 2 indicates the effect of binder to pigment ratio and temperature on colour strength of Blue pigment.

Table no.2

The results from table no 2 and Graph no.2 indicate the effect of pigment to binder ratio and polymerization temperature on the colour yield of blue pigment. The K.S value of 1% concentration of pigment for the pigment to binder ratio 1:2 is 12.53 and that of for 1:3 and 1:5 ratio are 12.86 and 13.02 at 1400C polymerization temperature. For the same concentration the K.S values at 1500C are 12.81, 13.09 and 13.14 respectively. Thus there is significant increase in the colour strength of blue pigment with increasing binder concentration and polymerization temperature. This can be attributed to the fact that 1:5 ratio of pigment to binder shows higher colour yield where good cross linking of polymeric film of binder is achieved and prints are brighter.

3.3 Effect of binder to pigment ratio and temperature on rubbing fastness of Red Pigment:

Table number 3 indicates the effect of binder to pigment ratio and temperature on rubbing fastness properties of Red pigment.

Table no. 3

Results from table no.3 show that the dry rubbing fastness properties of red pigment at 1% concentration with pigment to binder ratio 1:2 is 3-4 when polymerization is carried out at 1400 C and that of 1:3 and 1: 5 ratio are 3-4 and 4 respectively. This indicates that with increasing pigment to binder ratio, dry and wet rubbing fastness properties of pigment get improved which can be attributed to the fact that the increased ratio ensures better cross linking of binder polymeric film because of increased cross linking sites and there by enhance the rubbing fastness properties. Similar trend was observed in the case of wet rubbing fastness at all pigment concentration levels.

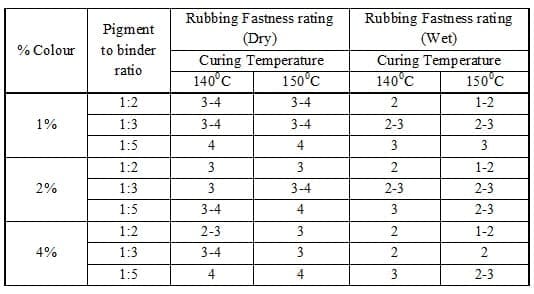

3.4 Effect of binder to pigment ratio and temperature on rubbing fastness of Blue Pigment:

Table number 4 indicates the effect of binder to pigment ratio and temperature on rubbing fastness properties of Blue pigment

Table no 4

Results from table no.4 show that the dry rubbing fastness properties of blue pigment at 1% concentration with pigment to binder ratio 1:2 is 3-4 when polymerization is carried out at 1400 C and that of 1:3 and 1: 5 ratio are 3-4 and 4 respectively. This indicates that with increasing pigment to binder ratio, dry and wet rubbing fastness properties of pigment get improved which can be attributed to the fact that the increased ratio ensures better cross linking of binder polymeric film because of increased cross linking sites and three by enhance the rubbing fastness properties.

Similar trend was observed in the case of wet rubbing fastness at all pigment concentration levels.

4. Conclusion:

From the results it can be concluded that,

1. Nonwoven fabric has greater share in market and considering the environmental aspect it is considered as substitute for plastic packaging material.

2. The packaging material made of nonwovens can be made attractive by printing process.

3. Since pigment printing offers prints with better print economy and ease of application, printed nonwovens have more demand in market.

4. Nonwoven fabric printed with pigment exhibited brighter prints with increased colour yield which was measured in terms of K/S value with increasing pigment to binder ratio. 1:5 ratios produce brighter prints of increased colour yield as compared with 1:2 and 1:3 ratios.

4. The dry and wet rubbing fastness properties of pigments were also found improved with increasing pigment to binder ratio.

5. Pigment to binder ratio of 1:3 and 1:5 can be recommended for printing nonwoven fabrics using pigments.

References:

1 K. Haggag, M. M. El-Molla, N. O. Shake , N. A. Alian , F. N. El-Shall, “Use of the Novel Synthesized Aqueous Binders for Pigment Printing Cotton Fabrics Using Three Modes of Fixation”, International Journal of Textile Science 2012, 1(6) 49-61

2. W. Schwindt, G. Faulhaber, “The Development of Pigment Printing Over The Last 50 Years”, 166 rev.prog, coloration,14(1984)

3. M. D. Teli and V. Y. Ramani, “American Dyestuff Reporter”, 81, 32-7 (1992).

4. V. Shukla, M. Bajpai, D.K. Singh, M. Singh, R. Shukla, (2004) “Review of basic chemistry of UV-curing technology”, Pigment & Resin Technology, 33 5, 272 – 279 (2004).

5. Mansoor Iqbal, Javaid Mughal, Munazza Sohail, Arsheen Moiz, Kamran Ahmed, Khalil Ahmed, , “Comparison between Pigment Printing Systems with Acrylate and Butadiene Based Binders”, Journal of Analytical Sciences, Methods and Instrumentation, 2012, 2, 87-91

6. A. Poehlmann, “Pigment Printing System,” Textile Industries Dyegist, Vol. 11 (10), 1992, pp. 4-9.

7. W. C. Miles, “Textile Printing,” 2nd Edition, Society of Dyers and Colorist, Bradford England, 2004.

8. V. A. Shenai, “Technology of Textile Printing,” 2nd Edition, Sevak Publisher, Mumbai, 1990.

9. J. R. Aspland, The colouration and Finishing of Nonwoven Fabrics, School of Materials Science and Engineering,Clemson University,

10. AATCC Test Method-8, Color Fastness to Crocking, 2005.