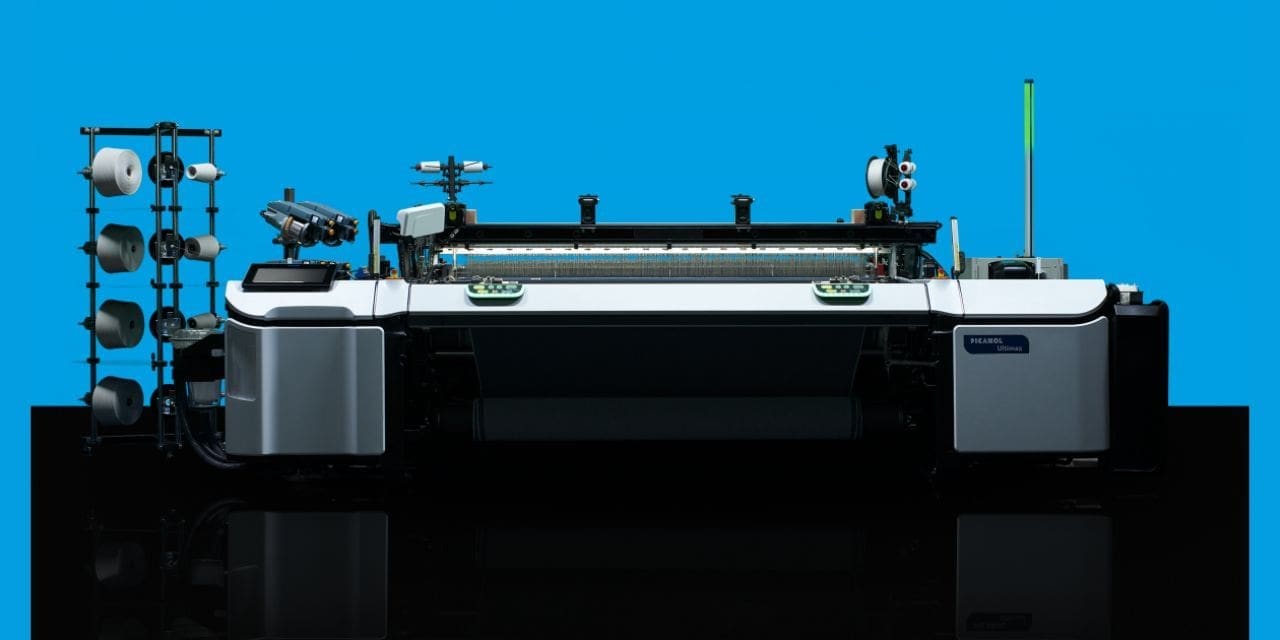

At ITMA 2023, Picanol, the world’s leading weaving machine manufacturer, will be presenting its latest high-tech weaving machines and services at Booth B201 in Hall 6. ITMA is the world’s most influential textile and garment technology exhibition and it takes place from June 8 – 14, 2023, in Milan (Italy). The eye-catcher at the Picanol booth will be the world premiere of an all-new and revolutionary rapier weaving machine, the Ultimax, that will become available in the first quarter of 2024. In total, Picanol will have 12 machines on display at ITMA 2023. In addition to 6 rapier weaving machines, Picanol will also present 4 airjet weaving machines featuring new developments.

Furthermore, a rapier machine in Jacquard execution will be on display at the Bonas booth and an airjet machine in

Jacquard execution will be presented at the Stäubli booth.

“Picanol has sold more than 130,000 rapier machines worldwide since the launch of our first rapier weaving machine, and we have challenged ourselvesto further improve our current and highly successful OptiMax-i Connect rapier platform. The result is the brand-new Ultimax rapier weaving machine that focuses on three main benefits: ultimate performance and high-quality output, readiness for the sustainability requirements of tomorrow, and the greatest ease of use thanks to a maximum level of digitization. In addition, the classic Picanol exterior design of the machine has been radically disrupted, to make it clear from the outside how revolutionary Ultimax is on the inside,” explains Johan Verstraete, Vice President Weaving Machines.

“Creating a worthy successor to the OptiMax rapier generation, of which over 60,000 units are running worldwide, was a real challenge. But combining 85 years of experience with new ideas and technologies has resulted in the all-new and revolutionary Ultimax rapier machine. It excels in the fields of performance and quality, it is designed with sustainability as the baseline, and the high degree of digitization results in a previously unseen ease of use.”

Innovations in airjet technology

ITMA 2023 will also be the moment that Picanol launches a speed increase on its airjet platform, the OmniPlus-i Connect. This is another example of how Picanol sets the benchmark in the industry. Also on display for the very first time will be a brand-new leno system, the o-Leno, which combines smart performance, user-friendliness, and intuitive control at its best.

Novelties in PicConnect

With PicConnect, Picanol is centralizing its digital tools and services in one new fully digital platform. At ITMA 2023, visitors will be able to discover all the benefits and latest features of PicConnect to leverage the full extent of the possibilities offered by its Picanol weaving machines. Among other things, the recently released features such as alerting, access control, the action center, and the export of monitoring data should catch the attention of many visitors.

Below our detailed overview of the machines and highlighted features:

1. Ultimax-4-R-220 Denim

Warp: Co Nm 17/1

Density: 19 ends/cm

Drawing in width: 210 cm

Weft: PBT Nm 22/1

Density: 18.5 picks/cm

Highlighted features: Recycled yarn ready • EcoFill 4c • Electronic Right Gripper Opener (ERGO) • Gripper stroke measurement • Gripper tape monitoring • Guided Gripper GC • Quick Style Change (QSC)

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Gripper stroke measurement • Climate monitoring • Shed calculation •PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation •On-loom Picascope

2. Ultimax-8-R-360 Voile

Warp: Pes 76f24/800 dtex

Density: 30 ends/cm

Drawing in width: 336 cm

Weft: Pes 76 dtex + Pes 22 dtex +Pes 167 dtex + Pes 330 dtex + fancy Nm 3

Density: 18- 28 picks/cm

Highlighted features: OptiForce take-up • QuickStep weft presenter • On-loom Picascope • Tension Display (TED) • Electronic Filling Tensioner (EFT) • SmartCut • e-Leno

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept •Gripper stroke measurement • Climate monitoring • Shed calculation •PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation •On-loom Picascope

3. Ultimax Terry-8-J-260 Terry towel

Warp: Ground: Co Nm 40/2

Pile: Co Nm 40/2

Density: 11 ends/cm

Drawing in width: 253 cm

Weft: Co Nm 27/1 + Co Nm 40/2 + Cv 500 dtex + Chenille Nm 8.5

Density: 19- 120 picks/cm

Highlighted features: Pneumatic pile backrest • Pile monitoring • Pile formation system • BlueTouch display • Guided Gripper GCv • Needle roller • Needle roll control

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Gripper stroke measurement • Climate monitoring • Shed calculation •PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation •On-loom Picascope

4. Ultimax-12-J-340 Flat carpet

Warp: Pes 500f144 dtex

Density: 32 ends/cm

Drawing in width: 340 cm

Weft: Chenille Nm 3.5 + Cv Nm 27/4 + BCF 1900f363 dtex

Density: 35 picks/cm

Highlighted features: OptiForce take-up • Free Flight with raceboard (VB) • Electronic Right Gripper

Opener (ERGO) • BlueBox electronic platform • BlueTouch display • Smart signal lights • SUMO drive concept

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Gripper stroke measurement • Climate monitoring • Shed calculation •PicConnect enabled Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation •On-loom Picascope

5. OptiMax-i Connect-4-P-430 Anti hail

Warp: PE 722 dtex – ø 0.32 mono

Density: 2.9 ends/cm

Drawing in width: 410 cm

Weft: PE 722 dtex – ø 0.32 mono

Density: 2.9 picks/cm

Highlighted features: Guided Positive Grippers (GPG) • Waste ribbon winder • Waste ribbon detection • Direct Warp Control (DWC) with rolling tubes 4 • New filling cutter for coarse yarns Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Climate monitoring • Shed calculation • PicConnect enabled Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation

6. OptiMax-i Connect-4-R-540 Coating

Warp: Pes 1.100f210 dtex – TO

Density: 7 ends/cm

Drawing in width: 530 cm

Weft: Pes 1.100f210 dtex – TO

Density: 7 picks/cm

Highlighted features: Free Flight with raceboard (VB) • Electronic Right Gripper Opener (ERGO)

• Direct Warp Control (DWC) • BlueTouch display • Smart signal lights •Laserstop Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Climate monitoring • Shed calculation • PicConnect enabled Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation

7. TerryPlus-i Connect-6-D-260 Terry towel

Warp: Ground: Co Nm 40/2

Pile: Co Nm 34/2

Density: 23 ends/cm

Drawing in width: 248 cm

Weft: Co Nm 40/2 + Co Nm 24/1

Density: 19.5 – 144 picks/cm

Highlighted features: Pile formation system • Pile monitoring • Pneumatic pile backrest •SmartShed •AirMaster •Needle roll control • Pick Repair Automation (PRA II Plus)

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept •Climate monitoring • Shed calculation • PicConnect enabled Monitor package: Access control • OptiStyle • Raw material use

Smart savings package: Power monitoring • AirMaster with integrated air consumption meter •Adaptive Relay Valve Drive (ARVD II Plus)

Automation package: Pick Repair Automation (PRA II Plus) • Prewinder Switch-Off (PSO) • AutoSpeed • Harness frame stroke measurement & Shed simulation

8. OmniPlus-i Connect-4-D-340 Sheeting

Warp: Co Nm 102/1

Density: 72 ends/cm

Drawing in width: 301 cm

Weft: Co Nm 68/1

Density: 41 picks/cm (Double pick)

Highlighted features: Twinjet • Air Tucking-In (ATI) • Electronic Selvedge System (ELSY) • SUMO drive concept • Sensor dashboard • OptiStyle • PicConnect enabled

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Climate monitoring Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use

Smart savings package: Power monitoring • AirMaster with integrated air consumption meter •Adaptive Relay Valve Drive (ARVD II Plus)

Automation package: Pick Repair Automation (PRA II Plus) • Prewinder Switch-Off (PSO) • AutoSpeed • Harness frame stroke measurement & Shed simulation

9. OmniPlus-i Connect-4-D-190 Car seat

Warp: Pes 167f48 * 2 dtex

Density: 27 ends/cm

Drawing in width: 180 cm

Weft: Pes 167f48 * 2 dtex

Density: 27 picks/cm

Highlighted features: SmartShed • Blue11 EasySet prewinders • Picanol Knot Extractor (Full PKE) • Adaptive Relay Valve Drive (ARVD II Plus) • CordLess • Quick Style Change (QSC) • Raw material use

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Climate monitoring Shed calculation • PicConnect enabled Monitor package: Access control • OptiStyle • Raw material use

Smart savings package: Power monitoring • AirMaster with integrated air consumption meter • Adaptive Relay Valve Drive (ARVD II Plus)

Automation package: Pick Repair Automation (PRA II Plus) • Prewinder Switch-Off (PSO)• AutoSpeed • Harness frame stroke measurement & Shed simulation

10.OmniPlus-i Connect-4-P-190 Bottom weight (100% recycled yarn)

Warp: Pes/Co recycled (67/33) Nm 17/1

Density: 23.7 ends/cm

Drawing in width: 167 cm

Weft: Pes/Co recycled (67/33) Nm 28/1

Density: 26 picks/cm

Highlighted features: o-Leno • Blue22 EasySet prewinders • Pick Repair Automation (PRA II Plus) •hybrid harness frames •Shed angle indicators • BlueTouch display • Access control

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept •Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use

Smart savings package: Power monitoring • AirMaster with integrated air consumption meter • Adaptive Relay Valve Drive (ARVD II Plus)

Automation package: Pick Repair Automation (PRA II Plus) • Prewinder Switch-Off (PSO) • AutoSpeed • Harness frame stroke measurement & Shed simulation

11.PicConnect corner

Visit the PicConnect corner of our booth to discover everything you need to know about this platform.

All of the weaving machines at our booth will be connected to PicConnect.

12.OmniPlus-i Connect-4-J-220 African damask (Stäubli – Hall 6 – Booth A201b)

13.OptiMax-i Connect-12-J-190 (Vandewiele/Bonas – Hall 10 – Booth B201c)

About Picanol

For more than 85 years, Picanol (www.picanol.be) has played a pioneering role in the global textile industry and it is currently the world’s leading weaving machine manufacturer. Picanol develops, manufactures, and sells high-tech weaving machines based on airjet and rapier technology. Picanol offers upgrade kits, spare parts, training, troubleshooting services, and also digital services for its weaving machines through the PicConnect platform.

Picanol has its headquarters in Ieper (Belgium) and it employs more than 1,200 people worldwide.

Picanol is part of Picanol Group, a business unit of Tessenderlo Group (Euronext: TESB). Tessenderlo Group is a

global industrial group that focuses on agriculture, valorizing bio-residuals, machinery, mechanical engineering,

electronics, energy, and industrial solutions for water management. At the heart of the strategy of the group lies

the conviction that “Every Molecule Counts”: in everything Tessenderlo Group does, it seeks to further valorize its

products and its processes, and to add value. For more information about Tessenderlo Group, please visit

www.tessenderlo.com.

For further information or picture materials, please contact Ms. Femke Heens ([email protected] or +32

57 21 12 35).