Aniket Bhute , Ramchandra Sawant

- Scientist & Assistant Director, D.K.T.E. C.O.E.(Nonwovens), Ichalkaranji.

- Assistant Professor, Anuradha Engineering College, Chikhli.

e-mail: [email protected]; [email protected]

Abstract

Nonwovens producing include four stages, raw material preparation, web formation, web bonding, and finishing of nonwovens. The web bonding techniques affects the properties of the end products. Web bonding mainly classified as, needle punching, hydro-entangling, thermal bonding, stitch bonding, and chemical bonding. The paper focuses on different web bonding techniques and factors affecting properties of end products.

Keywords: Nonwovens, mechanical bonding, thermal bonding, chemical bonding, wipes, textiles

- INTRODUCTION

In today world, nonwovens, as highly engineered fabrics can be seen in every areas of life with their many attractive and versatile properties. They are attractive because of high capacity production availability and cost effectiveness; they are versatile because with so many different techniques, different performance requirements can be met. It can be easily understood, like for every other product, there is an expectation from nonwovens to have better quality and standardization. In order to improve the quality and provide standardization, it is necessary to understand property – structure relationship. As it is obvious that structure is produced by using proper materials and the proper processing method, hence property, material, structure and process dependence can be easily realized. However, proper material production and selection is out of subject when dealing with mechanism and performance of nonwoven processes. Thus, process – property – structure relationship must be well understood in order to meet expectations and requirements with the nonwoven product. Structural factors, which are affected on nonwoven fabric properties, can change one procedure to other. Some of them are stem from bonding procedure and can be listed as following; bonding type, bonding area, bonding density, bonding strength, bonding point distribution, and fiber movement availability within the bonding area. Some others are related with structure of fibers, such as fiber orientation and distribution, fabric dimensions and dimensional stabilities, interface properties between binder and fiber, fabric porosity, and pore size distributions. In this study, we will try to examine the working principles, potential uses, and effectiveness of bonding techniques to give an idea about property – structure relationship based on bonding type.

- BONDING METHODS for NONWOVENS

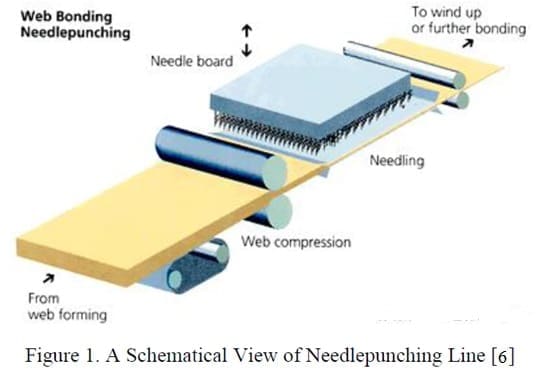

Needle punching

It is the mechanical bonding method that has the principal mechanism of interlocking and intermingling of fibers by means of barbed needles. Besides mostly used web formation methods of carding and carding with crosslapping, air laid web formation and spunbond web formation are other possible web formation methods for needlepunched bonding technology . Following web formation procedure fibers are fed to the needling zone known as needle loom. In needle loom there are five main components available; needle board, needles, bed plate, stripper plate, and delivery rolls. Bonding throughout the nonwoven mat occurs by the penetration of the needle into the fibrous web layers and in this way, highly loft structures can be produced. In order to have a precise needling, needles travel inside the holes which were placed on the needling plates and they make forward and backward motions. The primary component of needle punching, needle, has its own essential components to provide better bonding and mingling effects. On a needle, barbs and working blades have vital responsibilities to blend the web and give the properties to the structure . On the fabric surface it is possible to realize needling marks, which are stem from pretty high punching movement. In needle punched nonwovens, it is possible to mention about two different fiber groups, some of them are directly exposed to needle impact and others are indirectly affected, even some are unaffected. Thus, these two groups compensate each other and the undesired effects of needle punching are minimized. The depth of fiber penetration and needle marks are related with bonding quality, namely fabric quality and performance properties. Related with those mentioned factors, number of barbs, punch density, needling speed and fiber types are other important quality parameters for needle punching process. One of the most remarkable characteristic of the needlepunched nonwovens is their high porosity and high pore distributions . Preneedling is an optional step which improves the quality and provides better properties to the end product. With pre-needling the web thickness is reduced, the strength is increased and more uniform structure can be produced.

Needle punched nonwovens are used in many application fields respect to their desirable properties. Dimensional stability, permeability, drapeability, moldability, acoustic and thermal properties, tensile properties are few of them. Depend on these properties needle punched nonwovens are used in automotive, construction, home furnishing industries, geotextiles, shoe felts, blankets, filters, insulators and so on and so forth [2].

Hydro-entangling

Following the web forming process, fibrous web was transferred into the bonding stage on a conveyor belt. Heavily dry laid systems are used by many manufacturers to get spunlace nonwovens, but wet laid and polymer laid web forming applications are in use as well. Although most of the companies prefer dry laid web forming units, their machinery types and process orders may vary from one to another. In bonding stage main parameters are impact force produced by high pressure water jets, structure of the support members, fiber types, speed of the conveyor belt, prewetting of the web, and lastly the number of manifolds in use. It is obvious that these parameters are also affected on the quality of the end product, hydro entangled fabric.

Unlike other fabric formation methods, it is difficult to understand the mechanism of the hydro entangling in fabric formation level, because both conveyor belt and water jet have very high velocity values during the process and it is difficult to realize what’s happening when water jet hits to the fiber web. What’s more, there are several other factors available in addition to jet pressure and they are highly effective when energy transfer occurs between fiber web and water jet. Nevertheless, the amount of pressure that is applied on a web is far more important in defining bonding quality. If water jets are applied with low pressure values only some fiber entanglement on the web surface can be obtained. Reversely, if water jets

are applied with high pressure then both fiber orientation directions may change and also fibers may deform and break . Apart from the water jet effect, in the second plan, supporting structure type and entangling density are other parameters that affected on the performance of the final product . Hydroentangled fabrics heavily consumed in wipes industry and medical nonwoven industry because of their additive free, lint free, soft, strong, and cost effective characteristics. Also they are used in several other industries such as automotive component manufacturing, filtering, packaging, insulation, roofing, geotextiles, diapers, and hygiene products. It is possible to extend the application fields of hydroentangled fabrics for following products; interlinings, mattress pad covers, scrub suits, towels, flannel replacement fabrics, washable domestic fabrics, high temperature protective clothing, artificial leather and so many others . Spunlace nonwovens are not perfect structures with their poor stretch recovery, poor abrasion resistance and poor creep resistance . However, some properties are accepted relatively good when evaluated with some other criteria. For instance, when considering cost effectiveness, aesthetic may not be a concern; when considering the application in filter industry the strength is not real requirement.

Thermal Bonding

In order to perform thermal bonding of the fibrous web structures there is a prerequisite that must be met. Fibrous web must include thermoplastic fibers or at least thermoplastic powders. Most commonly used thermoplastic fibers are polypropylene, polyester, nylon, polyethylene and some others. There are basically four types of thermal bonding available in the market. In through – air bonding method, heated air applied on a fiber web when it moves on a conveyor band. In this method it is important to adjust the length of flat bed, temperature of the heated air and throughput speed to enable sufficient dwell time. This dwell time is pretty important for some certain basis weight webs to provide required thermal equilibrium. This method is applied generally to high loft structures to get homogenous bonding. In impingement method (another name for through – air bonding), web is transported to the oven and from the nozzles hot air is impinged to the web surface and bonding formation is occurred. As it may be guessed, in this method the bonding efficiency on the surface can be good while it is very few, even close to zero, in the depth of the web. The efficiency of the bonding is affected from the following factors; thickness of the fabric, speed of the belt (amount of the throughput), and temperature of the heated air which are required to be adjusted properly .

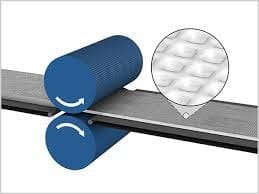

In calendar bonding, web is passed between heated rollers and bonding occurs at that time. If the rollers are smooth then every cross-over point can be bonded and is called as area bonding. The produced fabric with this method will be strong, stiff, and relatively thinner. In another version, point bonding is seen and heat is applied in selected areas on the web due to the engraved patterns on one of the rollers. Between bonded areas the fibers are formed bridges, so they are called bridging fibers. Sometimes the fibers are excessively melted at contact points with rollers and they flow around the bonding points and in this way, secondary and less strong bonds might be formed. In infrared bonding technique, radiative mode of heat transfer is performed. It is not preferred method as a result of its high cost and insufficient bonding characteristics. Last form of thermal bonding is ultrasonic bonding. It is based on a vibrational motion stem from ultrasonic frequency formed in a device which is called as a horn and by means of energy conversion, the bonding takes place. When the web comes into a contact with the horn, it starts to vibrate and the passage for web narrows down. Then thermal energy is generated depends on frictional force between web and horn surface and bonding takes place. Although it is not economical way of bonding, it is suitable method to join laminates and produce quilt type products.

The explicit characteristics of thermal bonding are low maintenance cost, low raw material and energy costs, product versatility, smaller space requirements, better quality characteristics, increased line production and reduced cleaning time of the system [9,10].

In numerous areas, thermal bonded nonwovens can be seen. The most important ones are, hygiene disposable products, durable building and construction materials, air and water filtration media, horticultural products, clothing, footwear, roofing felts, carriers, tea bag applications, surgical gowns and drapes and so on and so forth [4].

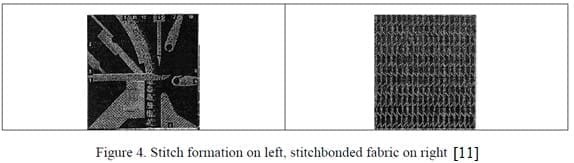

Stitch bonding

It is formed by stitching of the fiber bundles with fibers or yarns. Fabric generally may have clear stitching pattern on one side or both sides. There are three main types of stitch bonded fabrics available in the market; fabric with one side stitches, fabric with one side stitches and one side projection of pile of pleating fibers, and fabric with two side stitches. Generally in stitchbonded fabrics, yarn stitches aligned within the fabric plane. The performance of the stitchbonded nonwovens are dependent on the web density and structure, stitching yarn structure, stitch density, machine gauge, stitching yarn tension and stitch length. The number and size of stitch holes are determined by the previously given factors. The tensile strength in MD direction and extensibility in CD direction can be adjusted by the stitch construction. The needle motion is very similar to warp knitting technology since it is adapted from warp knitting, With this technology it is possible to change fabric physical properties such as flexibility, and strength by a proper stitch yarn selection. In order to produce flexible fabrics, Lycra is used as a stitch yarn, and in order to produce strong fabrics, Kevlar is preferred. Although stitchbonded fabrics are used to produce vacuum bags, geotextiles, filters, and interlining, the biggest market is shaped by home furnishing industry. It is anticipated that stitchbonded fabrics may invade the woven market in near future.

Chemical Bonding

It is a versatile technology and fabric formation is materialized by the application of resin or latex to the structure. It is used in several areas such as industrial and food service wipes, dryer softener substrate, wet wipes and baby wipes, filtration media, and garment interlinings. The characteristics of the latex used for bonding nonwovens are very important because of their effects on performance of the nonwovens. Glass transitional temperature must be lower to pioneer easy processing. Also it must have proper backbone composition, functional groups, reactivity, molecular weight, and surfactant type. Otherwise durability, tensile strength, softness, hardness, elasticity, and many other properties might be badly affected because of the wrong latex selection.

There are four types of chemical bonding methods available in use. Print bonding is so similar to printing of the woven fabrics. Gravure roll printing and screen printing are the two common print bonding methods, where, gravure roll printing is used generally for the bonding of lightweight nonwovens. Spray bonding is another chemical bonding method that sprays latex on a web when moving on the conveyor belt. It is suitable for the bulky, high loft applications. Saturation as a third method comprises direct dipping of a fabric in a latex tank and performing drying in a dryer. This method has handicap that may change or destroy the uniformity of a fabric. Last method in chemical bonding which is called as foam bonding can be used for all types of nonwovens. It provides resiliency and softer hand to the fabric. In order to dry the fabrics, hot cans, infra red technology, impingement, microwave, radio frequency and some others are used. To provide a high liquid absorption capacity on wipes, to resist dry cleaning and washing of interlinings, to maintain barrier properties on some type of hygiene and medical products, binders are applied to the fabrics. To have better abrasion resistance and good handling, the outer part of the shoes are made from chemically bonded nonwovens. Also in automotive industry, upholstery and bedding applications, insulation applications, prefilters and roofing membrane applications, chemical bonding methods are used.

- CONCLUSIONS

In this study basically three main bonding techniques for nonwovens, mechanical bonding, thermal bonding, and chemical bonding were reviewed. It was seen that among them, mechanical bonding was divided into three main subgroups; hydroentangling, needlepunching, and stitchbonding. While other techniques also differ from one to another, their differences were limited with only their application methods such as calendar bonding – through air bonding, and print bonding – spray bonding. It is clearly understood from the descriptions in the text that contribution of each bonding methods to the final nonwoven products may differ. The functionality and the performance characteristics of the products such as strength, durability, drapeability, application field, barrier properties, and some others can be classified among these differences. Thus, the selection of proper bonding method and material is pretty important in defining final properties and quality of the nonwoven based products. Moreover, since nonwoven mats are produced with very high production rates, the process variables and parameters should be adjusted very carefully and sensibly. Therefore, in order to prevent high amount of loss in the production stage, well-trained labors must be employed for highly engineered nonwoven fabric production.

- REFERENCES

- Pourdeyhimi, B., Kim, H., S., The Role of Structure in Mechanical Properties of Nonwoven Fabrics, Textile Asia, Vol: 32, 2001

- The Needlepunch Primer, INDA, 1995

- Krcma, R., Nonwoven Textiles, Textile Trade Press, Manchester, 1967

- Russell, S., J., Handbook of Nonwovens, Woodhead Publishing Ltd., 2007

- Mrština, V., Fejgl, F., Needlepunching Textile Technology, Elsevier, NY, 1990

- edana.org, Retrieved on 06.19.2011

- https://www.engr.utk.edu/mse/Textiles/Spunlace.htm, Retrieved on 06.18.2010

- Batra, S., K., Pourdeyhimi, B., Shiffer, D., Fiberweb and Nonwoven Production Class Notes, 2004

- Turbak, A., F., Nonwovens: Theory, Process, Performance, and Testing, Tappi Press, 1993

- Chand, S., Bhat, G., S., Spruiell, J., E., Malkan, S., Structure and Properties of Polypropylene Fibers During Thermal Bonding, Thermochimica Acta, 2001

- Barnard, W., Spunlace Items for Healthcare, INDEX 87.