“Kalamkari” is derived from the Urdu word “qalam” and Persian “Kalam,” meaning pen, and “Kari,” meaning artistic work. This art form involves using a pen-shaped twig to decorate handloom fabric with natural dyes. It is practiced by artists from various communities in two districts of Andhra Pradesh: Srikalahasti of Chittoor district and Masulipatnam of Krishna district.

Kalamkari’s roots can be traced back to the Indus Valley Civilization, with painted or printed fabrics discovered in the 8th century C.E. The art flourished during the Mughal period, with items like kanat or tent covers and prayer mats being made. The hub of this art form was Golconda, Chennai, and Masulipatnam, with artistic designs catering to Persian tastes in Golconda and directly under the patronage of temples in Srikalahasti.

Kalamkari fabric items such as bed covers, linen, and clothing for men and women were exported to Europe and Iran since the 15th or 16th century. The pen was replaced by block-printing in the 19th century.

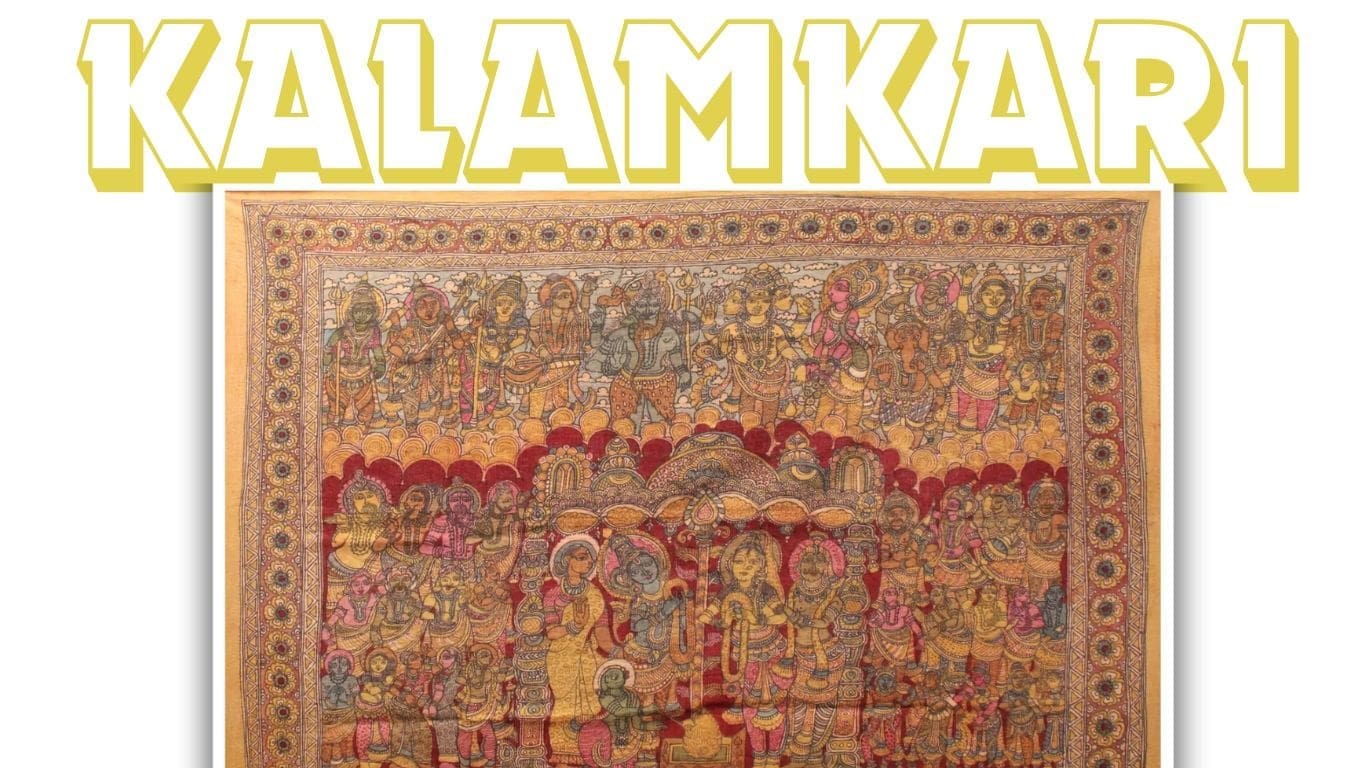

Kalamkari paintings are more extensive than other traditional fabric paintings, with scenes from Ramayana and Mahabharata depicted in a row with a narrative written beneath it. The paintings are not just religious, moral, and spiritual in character but also a means of recording social events. Motifs based on flora and fauna, especially the “Tree of Life,” are also prominent.

The style of drawing in Srikalahasti is characterized by bold, black, angular lines inspired by temple murals, while in Masulipatnam, the majority of fabrics are meant for clothing, prayer mats, bed spreads, tapestry, and hangings, with a variety of motifs used.

A distinctive feature of Kalamkari is the use of vegetable colors by the artist, with dyes extracted from natural sources like roots, leaves, flowers, and fruits. In Srikalahasti, the cloth is directly painted on with a pen made from bamboo sticks with felt wrapped to it. In Masulipatnam, intricate lines of pen are transferred onto wooden blocks and printed on the cloth surface. The cloth is produced in a manner where the block makers, washer people, and printers work under the same roof.