- As it did 25 years ago with its laser technology, the Spanish company seeks to revolutionize the denim sector with Atmos, its eco-efficient alternative for garment washing.

- The Indra technological solution eliminates the use of pumice stone in the jeans finishing process forever.

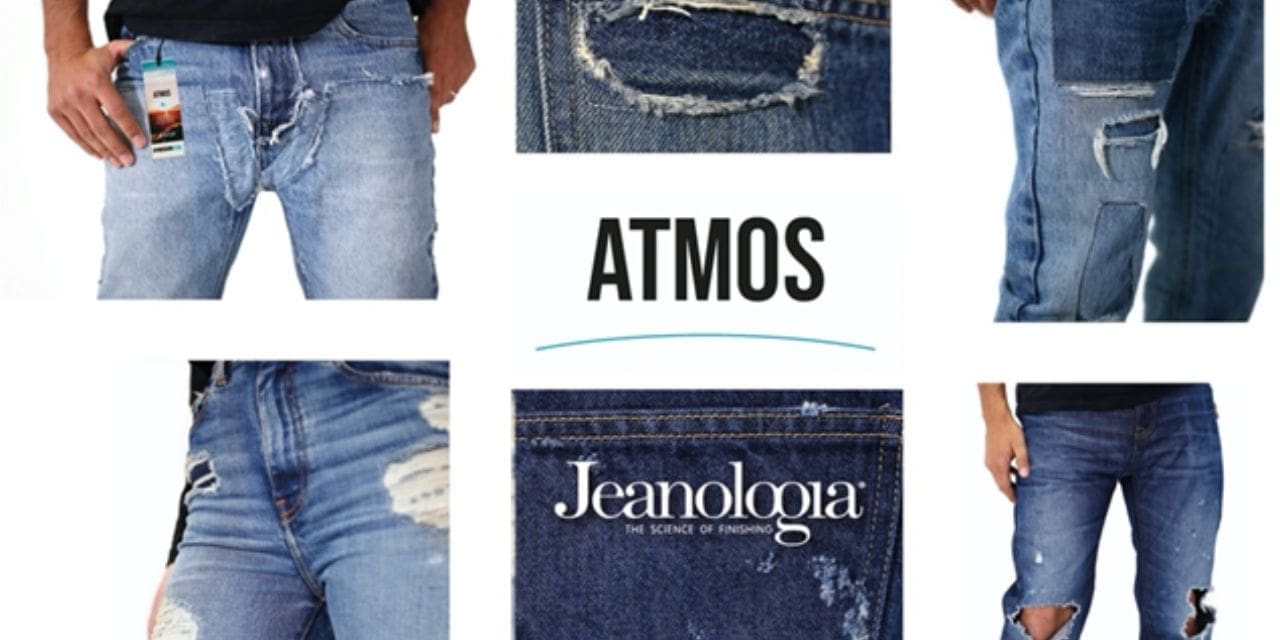

- It will exclusively present its Atmos Vintage collection of garments aged in a 100% sustainable way.

The leading company in sustainable technology for the textile industry, Jeanologia, will participate in the Kingpins Amsterdam fair, taking place from April 24th to 25th at the Sugarfactory in the capital of the Netherlands. Jeanologia will take advantage of this important sectorial event to unveil its innovative solution Atmos, which promises to revolutionize the denim world with an eco-efficient approach to garment washing, dispensing with water and pumice stone.

The traditional use of pumice stones in the stone wash process has long been a latent problem in the textile industry. Beyond its abrasive effect to achieve the famous look of the 60s, the stone weakens the fabric, making the durability of the garments and the subsequent recycling of cotton more difficult. The environmental consequences are equally concerning. Pumice stone, responsible for all pollution in the process, has been identified as one of the main contributors to the obstruction of water treatment plants. Additionally, the ecological cost associated with the estimated annual consumption of more than 2 million tons of this material for the denim industry is simply overwhelming and a danger to our planet.

The new stone wash becomes atmospheric wash

Faced with these challenges, Jeanologia has developed a comprehensive technological solution: the INDRA system which, combined with its established G2 ozone technology, creates the ATMOS finishing process. This innovative combination allows jeans to age using only atmospheric elements, without the need for water or pumice stones. This breakthrough not only provides a practical solution to existing problems but, as Fernando Cardona, head of Jeanologia’s Brainbox, explains, “marks an important milestone in denim history of which we are very proud.”

The Atmos process with G2 + Indra technology offers an unprecedented, efficient, and sustainable alternative to the conventional stone wash process. It not only drastically reduces water usage by up to 96%, but also offers greater efficiency in the use of productive resources for companies in this sector. Additionally, it improves the quality of garments. As Fernando Cardona points out, “Atmos demonstrates that it is possible to combine authenticity with sustainability.”

Jeanologia revolutionized the textile industry 25 years ago with the implementation of its laser technology, now, the Spanish technological company commits again to drive and lead the change towards more sustainable practices in the fashion industry through this revolutionary garment finishing process. In the words of the head of Jeanologia’s innovation department, “INDRA allows us to achieve something unprecedented: aging garments using atmospheric elements, without the need for water or pumice stone. This represents a significant achievement in terms of sustainability and performance.”

Jeanologia expects to make this innovative process the most popular and sustainable finishing in the textile industry. The implementation of the Indra system in the market has shown significant initial progress. With a current capacity to process up to 50 million jeans, Jeanologia anticipates an exponential adoption of this technological system in the coming years, thus driving a fundamental transformation towards sustainable fashion.

Exclusive presentation of the ‘Atmos Vintage’ collection

The upcoming edition of Kingpins in Amsterdam will serve as a platform to the exclusive presentation of Jeanologia’s ATMOS VINTAGE collection, exemplifying the potential of this revolutionary process.

Inspired by the iconic denim finishes of the 60s and 70s, the collection merges craftsmanship heritage with cutting-edge technology. It has been produced entirely environmentally friendly, using laser and G2 Ozone technologies, and stands out for its bold style and attention to construction details. The looks, inspired by the timeless aesthetics of the 60s and 70s, are made with current fabrics and precise details in seams, patches, and distressing. A ‘tech-artisan’ collection that not only celebrates the nostalgia of past decades but also sets a standard for authenticity and sustainability in contemporary fashion.

“This year, at Kingpins Amsterdam, we present the most authentic and sustainable capsule we have made to date,” says Fernando Cardona, adding that their goal is to “inspire all brands and manufacturers in the textile industry gathering in Amsterdam these days, by allowing them to see with this collection that it is possible to achieve authentically vintage jeans in a 100% sustainable way; without using stones and with the minimal amount of water.”

Jeanologia: over 25 years transforming the textile industry

Since 1994, Jeanologia’ s mission has been to create an ethical, sustainable, and eco-efficient textile industry. The company collaborates closely with brands, retailers, and their suppliers on their transformative journey, offering disruptive technologies, innovative software, and a new operational model. Their groundbreaking solutions, including laser technology, G2 ozone, Dancing Box, e-flow, and H2Zero, have revolutionized the textile industry, providing limitless design and garment finishing possibilities. These advancements not only reduce costs but also conserve water, energy, and chemicals, ensuring zero pollution.

In 2024, Jeanologia celebrates the 25th anniversary of its pioneering laser technology, launched in 1999, which revolutionized denim finishing, replacing harmful practices and eliminating the use of harmful substances. With the same purpose in mind, Jeanologia now faces the challenge of reducing the environmental impact of the garment dyeing process – one of the most polluting in the industry – through its revolutionary ColorBox technology.

With more than two decades of sustainable innovation, Jeanologia remains committed to creating an eco-efficient and ethical textile future and encourages all industry stakeholders to get behind its Mission Zero: dehydrate and detoxify the textile industry. No more water and toxic chemicals used in garment finishing around the world