Introduction:

“Continuous Innovation” is a key element in getting success in Technical textile industry. One needs to be innovative in production, process & even in marketing strategies.

With the continuous advancement in various fields like healthcare and hygiene, sports, protective textiles, and growing requirements from many industries, the existing fibers is being modified and new fibers are being developed to meet specific and stringent requirements of the technical applications. The fiber and polymer technologists have been continuously innovating new fibres to meet growing demands of high performance and functional textiles. The functional property requirement varies from sector to sector e.g. it is a fibre with high tenacity, high modulus and less weight for the application of filtration and sports textiles. In the case of medical and hygiene products, it should be free from toxic and biodegradable. For protective textiles, fibers should be high resistance to corrosive chemicals and high resistance to elevated temperatures, flames and very high hydrophilic.

In fact, in case of apparels, the global trend is shifting from occasion specific clothing to function based clothing where fabric properties play major role. Some of the trends like temperature sensitive& IT embedded technical garments will be gaining more importance in coming future. Increasing awareness on climatic changes like global warming, eco-friendly concept & enormous industrial growth will be leading to more focus on function based clothing than need specific clothing. These clothing consist of fibres with inherent functional properties. Technological advancement plays important role in development of high performance and specialty fibres which differ according to their specific properties & end-uses.

Major High Performance Fibres:

Glass Fibre: Glass fiber is the oldest and most familiar, high-performance fibre. Fibres have been manufactured from glass since the 1930s. Although early versions had high-strength, they were relatively inflexible and not suitable for several textile applications. Today’s glass fibres offer a much wider range of properties and can be found in many end uses, such as insulation, fire-resistant, and reinforcing materials for composites.

Glass Fiber

Carbon Fiber: Carbon fiber, alternatively graphite fiber, carbon graphite or CF, is a material consisting of fibers about 5–10 μm in diameter and composed mostly of carbon atoms. Carbon fibre may also be engineered for strength. Carbon fibre variants differ in flexibility, electrical conductivity, thermal and chemical resistance. Carbon fibre found its applications in automobile, aircraft, sport equipment and carbon electrode etc.

Carbon Fiber

Aramid Fiber: Aramid fiber is the best known of the high-performance, synthetic, organic fibres. Closely related to polyamides, aramids are derived from aromatic acids and amines. The high impact resistance of the para-aramids makes them popular for ‘bullet-proof’ body armour. For many less demanding applications, aramids may be blended with other fibres.

Bullet Proof Jacket

PBI (Polybenzimidazole): PBI (polybenzimidazole) is another fibre that takes advantage of the high stability of conjugated aromatic structures to produce high thermal resistance. The ladder-like structure of the polymer further increases the thermal stability. PBI is noted for its high cost, due to high raw material costs and a demanding manufacturing process. The high degree of conjugation in the polymer structure imparts an orange colour that cannot be removed by bleaching. When converted into fabric, it yields a soft hand with good moisture regain. PBI may be blended with aramid or other fibres to reduce cost and increase fabric strength.

PBO (polyphenylenebenzobisoxazole) and PI (polyimide) are two other high- temperature resistant fibres based on repeating aromatic structures. Both are recent additions to the market. PBO exhibits very good tensile strength and high modulus, which are useful in reinforcing applications. Polyimide’s temperature resistance and irregular cross-section make it a good candidate for hot gas filtration applications.

Hot Gas Filtration

PPS (polyphenylene sulfide) exhibits moderate thermal stability but excellent chemical and fire resistance. It is used in a variety of filtration and other industrial applications.

Melamine Fiber: Melamine fiber is primarily known for its inherent thermal resistance and outstanding heat-blocking capability in direct flame applications. This high stability is due to the cross-linked nature of the polymer and the low thermal conductivity of melamine resin. In comparison with other high-performance fibers, melamine fibres offer excellent value for products designed for direct flame contact and elevated temperature exposures. Moreover, the dielectric properties, cross-section shape and distribution make it ideal for high- temperature filtration applications. It is sometimes blended with aramid or other high-performance fibres to increase final fabric strength.

Fluoropolymer (PTFE, polytetrafluoroethylene) offers extremely high chemical resistance, coupled with good thermal stability. It also has an extremely low coefficient of friction, which can be either an advantage or disadvantage, depending on the use.

HDPE (high-density polyethylene) can be extruded using special technology to produce very high molecular orientation. The resulting fibre combines high strength, high chemical resistance and good wear properties with light weight, making it highly desirable for applications ranging from cut-proof protective gear to marine ropes. Since it is lighter than water, ropes made of HDPE float. Its primary drawback is its low softening and melting temperature.

Ceramic Fiber: High-temperature insulation wool (HTIW), known as ceramic fiber wool until the 1990s, is one of several types of synthetic mineral wool, generally defined as those resistant to temperatures above 1000°C. The first variety, aluminium silicate fibre, developed in the 1950s, was referred to as refractory ceramic fibre. Applications envisaged are in gas turbines, both aeronautical and ground-based, heat exchangers, first containment walls for fusion reactors, as well as uses for which no matrix is necessary such as candle filters for high temperature gas filtration. Alumina and silicon carbide bulk ceramics are widely used for their high stiffness and good high temperature mechanical properties in air; however, they are generally weak due to the presence of critically sized defects.

Chemically Resistant Fibers: Chemically resistant organic polymeric fibres include those which are designed to resist chemical attack for acceptable periods during their service lives at both ambient and elevated temperatures. As a consequence of their inert structures they may also be flame resistant and so address markets where that property is also desirable.

Fluorinated fibres: PTFE, PVF, PVDF and FEP (ARH) and Chlorinated fibres: PVDC (ARH) are Chemically resistant fibers.

Thermally Resistant Fibers: Thermally resistant organic polymeric fibres include those that resist thermal degradation and some degree of chemical attack, notably oxidation, for acceptable periods during their service lives. Thermosets (HE and HS), Melamine–formaldehyde fibres, Basofil (BASF) (HE) are Thermally resistant fibres.

Specialty Fibres:

Different categories of specializedfibres available in market like Modal, Tencel, Coolmax, Cuproammonium Rayon, Kermel®, ThermoCool, Recron®, Bamboo, Linen, Acrylic& many more. .

Tencel: Fully degradable Tencelfibre manufactured from wood pulp is soft as silk, strong as polyester, cool as linen, warm as wool and as absorbent as cotton. Not only is Tencel environmentally friendly, but also is has been designed to be a lovely and wearable fiber. Modal is a semi synthetic cellulose & it is used alone or blended with other fibres. It offers soft hand-feel, good drapebility and comfort while wearing. It has good moisture regain and air permeability which is often considered better than cotton fabric; hence it is used in in household items such as pajamas, towels, bathrobes, under garments and bed sheets. It is a good material for exercise clothing and health suit, which can serve to benefit physiology circulation and health of the body.

Tencel Manufacturing Process

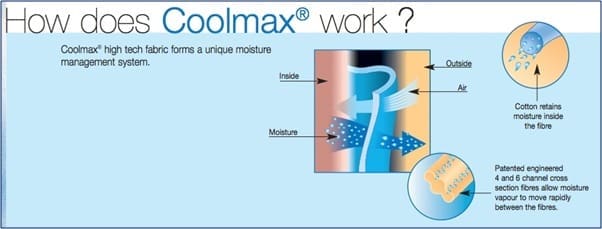

Coolmax: A trademark of Invista, is specially-engineered polyester fibre to improve “breathability” compared to natural fibres like cotton. The series of closely spaced channels creates capillary action that wicks moisture through the core and out to a wider area on the surface of the fabric which increases evaporation & now often woven with other materials like cotton, wool, Spandex and Tencel. Properties of CoolMax fabric allows wearer to keep sweat free hence it is widely used in garments of mountain climbing gear, casual sportswear, underwear & mattress covers. Other useful properties include resistance to fading, shrinking and wrinkling.

Cuprammonium rayon is also a specialized fibre used in lightweight summer dresses and blouses, sometimes in combination with cotton to make textured fabrics with slubbed, uneven surfaces.

Several other fibres /yarns are widely used various industrial & other functional applications like dope dyed polyester yarns used in high visibility garments; Kermel® having properties of non- inflammability, resistance to high temperature, resistance to abrasion, resistance to chemicals majorly used in protective clothing

ThermoCool fibre/yarns specifically designed to optimize the body’s natural thermo regulating capabilities through unique smart fiber cross sections that provide evaporative cooling or thermo-buffering according to the body’s needs. The garments produced from spun ThermoCool keep a body warm when it is cold and cool when it is hot leading to total body comfort and garment moisture management majorly used in active sports-wear.

Stretch yarn which is manufactured from Elastane fibre is commonly termed as Lycra or Spandex. Its applications in industry are mostly for body confirming garments such as sportswear, foundation garments, jeans & intimate apparels which ensures a stable shape during wearing. Other outstanding features beside shape retention are higher elasticity, smooth & supple hand-feel, lower moisture regain, resistance to pilling & resistance to abrasion. Global demand of stretch yarn will soar up in coming years because of increasing population.

There are other products like Organic Cotton, Compact, CSY, Melange, Slub, Multi count, Gassed, Mercerized, Fancy yarns, and Polyester/Nylon Filament yarn like DTY, FDY and POY in knitting and weaving also capturing huge markets.

Conclusion:

India has already positioned strongly in international market in terms of convectional yarns, now time has come to understand the importance of high performance and specialty fibres and yarns. Umpteen numbers of different yarns are developed in international market depending upon the properties, end-uses, different finishes, different textures and different looks.

Currently most of high performance and specialty fibres are being imported from outside in India and the demand for the same will be rising in future in multifold with kind of growth in the sectors like automobile, infrastructure, sports, health and hygiene & many industries etc. Indian entrepreneurs can capitalize this great untapped opportunity. Classic example is Recron®- a polyester fibre brand of Reliance Industries. It is developed in wide ranges depending on applications like Recron® Easy Stretch, Recron® FR ( Fire retardant), Recron® LP (low-pill tow and fibre), Recron® Super bright, Recron® Dyefast, Recron® Micrelle, Recron® 3S, Recron® Superdye& many more.

The fundamental strength of the Indian textile industry is its strong production base of wide range of fibre / yarns from natural fibres like cotton, jute, silk and wool to synthetic /man-made fibres like polyester, viscose, nylon and acrylic. Now, time has come to focus more on value added yarns which can fetch good margins to Indian spinners than conventional yarns& thereafter taking the final value addition in smart textiles.