KARL MAYER will showcase its new MULTI-MATIC® 32 for producing sample and short production warps. This new machine impresses with its excellent price-performance ratio. and offers all the advantages of the KAMCOS® 2 platform. Thanks to the integrated OPC UA interface in particular, the machine can be digitally networked and the operating data can be collected in real time.

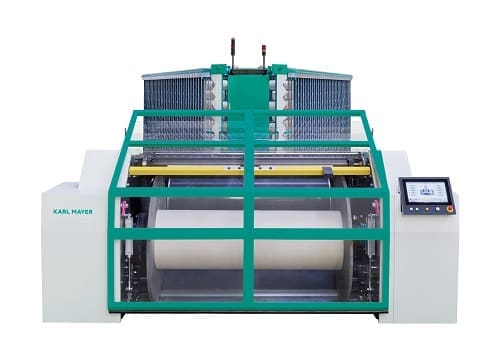

Regarding the direct beamers, KARL MAYER has consistently pursued its twin product line strategy. The new ISODIRECT was successfully launched at ITMA ASIA 2018 as a standard model, and the PRODIRECT will be presented to the public as a version for the premium market at the next ITMA in Barcelona. The latest electronic systems, the KAMCOS® 2 platform, and sophisticated technical solutions make this new machine the high-end model that achieves optimum levels in terms of quality and productivity.

Moreover, KARL MAYER will be showing the new stop motion MULTIGUARD as prototype. Positioned at the exit to the creel, this newcomer continuously determines the yarn tension values of all the yarns, thus, also controlling any yarn breakages and tension peaks.

Guests will be able to experience the latest generation of sectional warping machines via a live link at KARL MAYER’s German site in Hausen. The PROWARP® will be demonstrating its new features and capabilities. The latest innovations include a modern module for the camera-assisted recording of production data, which is important for the high reproducibility of beam build-up. The PROACTIVE Warping is also new. This new brand is a self-learning quality control system, which records the quality-relevant beam parameters by means of sensors and compares them with the target values. If any deviations occur, the production data are optimised accordingly when processing repeat orders. A high beam quality can be achieved, irrespective of the operatives.

With models and presentations, KARL MAYER will be showing innovative technical solutions for guaranteeing improved efficiency and sustainability in the denim production in its „Future of Textiles“ sector. One main focus in this context is the topic of SUSTAINABLE DENIM. KARL MAYER presents a newly developed technology for an indigo dyeing process in nitrogen atmosphere, which ensures an optimum setting of the dye in terms of solidity and brilliant tone, at the same time requiring less dye bath volume, chemicals and water. The dyeing process ensures highest efficiency.

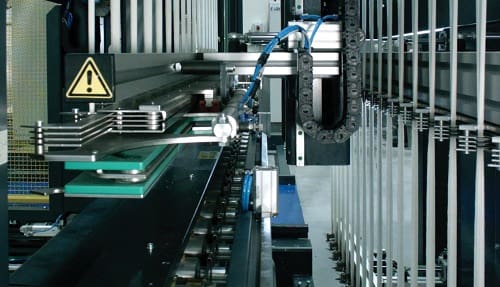

Also on show will be the new LINK-MATIC® system for the automatic knotting of the batches on the PRODYE-S indigo machine and the PROSIZE sizing machine. By means of this innovation it is possible to reduce retooling times to just a few minutes. The almost continuous production increases machine efficiency, at the same time reducing waste yarn and personnel expenditure. The perfect arrangement of the warp after retooling reduces the share of second-grade fabric.

More about SUSTAINABLE DENIM:

https://www.karlmayer.com/en/sustainable-denim/