“Digital could fulfill orders quickly, with very little waste and low cost per print—and Kornit Digital offered the best technology on the market.”

March 16th, 2021, Duesseldorf, Germany – Kornit Digital (Nasdaq: KRNT), a worldwide market leader in digital textile printing technology, announced Bratislava, Slovakia-based JEKA Studio has upgraded its Kornit Digital technology for single-step, digital direct-to-garment (DTG) production on demand, resulting in clear efficiency and bottom-line benefits for the textile services provider.

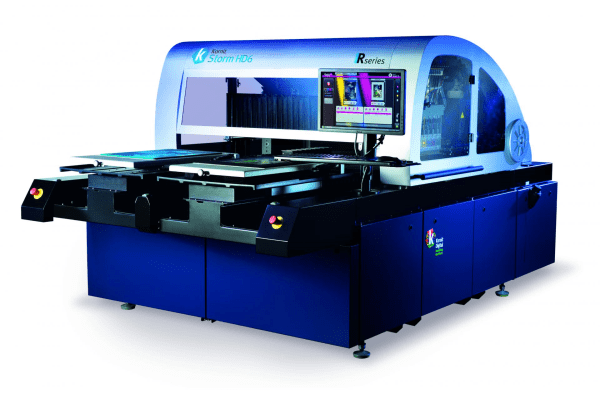

Having installed the Kornit Storm HD6 system with scentless fixation and eco-friendly NeoPigment inks, the business is able to produce garments at a 30% faster rate, while higher-quality impressions have delivered an increase in orders.

“Like many screen printers, we added digital textile print because it could fulfill orders quickly, with very little waste and low cost per print,” says Michal Krásnohorský, Owner at JEKA Studio. “Kornit Digital offered the best digital print technology on the market, and now the increased color gamut and retail quality has helped us grow our customer base, giving us reason to believe in future expansions.”

“It’s very common for commercial and screen printers to supplement their services with direct-to-garment, which offers immediate production on many fabrics, with unlimited graphic capabilities and a consistently low cost per print, in any quantity,” says Chris Govier, KDEU Managing Director. “JEKA Studio demonstrates how Kornit’s customers continue to grow and expand their capabilities as we continuously develop our systems, and continue to meet the demands of today’s web-driven, see-now-buy-now consumer mentality.”

About Kornit Digital