Lindauer Dornier GmbH, manufacturer of weaving machines and composite system product lines, would be presenting under the theme ‘The Green Machine’ at the upcoming ITMA exhibition—the International Textile Machinery Exhibition, to be held from June 20-26, 2019, in Barcelona, Spain. The company will also present its expanded service offering at the fair. In hall 4, stand B211, the company will present the latest machines and lines, “Made in Germany” for the sustainable, efficient manufacture of clothing, home textiles and technical fabrics and flexible, economical production of high-quality composite semi-finished materials.

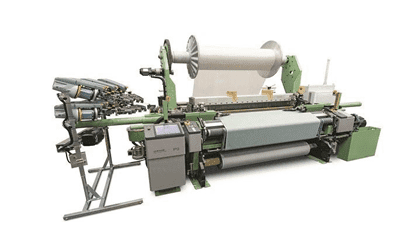

“The modern weaver faces many challenges: Digitalisation is advancing deeper and deeper into the fabric of the production chain, sustainability requirements are growing more demanding, new employees and experienced technicians are thin on the ground. Flexibility in manufacturing is turning into an existential question. At the upcoming ITMA, Dornier will present answers to these trends—in the form of the latest weaving machines and weaving solutions,” the company said in a press release. Dornier will premiere the new rapier weaving machine P2, which will be presented in its standard configuration for the first time in Barcelona. It combines the strengths of the P1 All-rounder with many innovations to equip the weaver optimally for the future. “We didn’t reinvent rapier weaving, but we improved every major aspect of the process,” says Thomas Laukamp, Dornier’s head of Advanced Technology Development Weaving Machines. Accordingly, with improved shed geometry and a more rigid frame, greater productivity, maintenance-free operation and optimised positive centre transfer movement, the P2 rapier weaving machine offers the highest flexibility and process reliability available on the world market.

The new machine structure with clearly defined primary and auxiliary modules represents a further advance. “The modular design and clear interfaces between the machine modules make conversion and expansion work simpler,” explains Laukamp.

He adds that this translates to greater investment security for the weaver, because the P2 can easily be adapted for processing different yarns for clothing, domestic and technical textiles as well as high-quality composite semi-finished materials. So the weaver can respond faster to unpredictable market developments. Dornier will also exhibit an encapsulated air-jet weaving machine, which is designed to bring different, individually controllable climate zones into the production workshop for the first time.