Skyrocketing demand for personal protective equipment (PPE) to combat the Covid-19 pandemic has led to a worldwide tightened supply of durable water repellents (DWR) and antimicrobials that are used in the textile finishing process. While the surging need for face masks and other protective medical gear can be a boon for the industry, as mills reopen, some textile finishers are reporting more difficulty procuring the chemistry to meet their customers’ needs and are seeking ways to maximize its yield as well as meet company sustainability objectives.

“The woven and knit mills, which are our main customers, were forced to stop production because of the coronavirus lockdown and/or lack of business due to lower demand and cancellation by brands and major retailers of orders already in the pipeline,” said Rick Stanford, Business Development Leader, Textiles for finishing equipment manufacturer Baldwin Technology Co. Inc. “However, as they are opening back up and starting to produce consumer products, I’m hearing that they are facing higher prices and longer lead times for DWR. It is more critical during this time than ever to reduce chemical waste.”

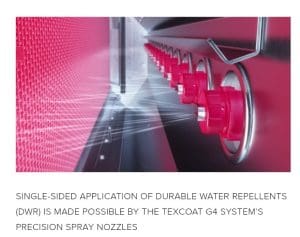

In the face of this shift in market demand, Baldwin’s revolutionary TexCoat™ non-contact textile finishing system delivers zero chemistry waste and minimized water and energy consumption. It provides the most advanced applicator of any high-tech finishing chemistries to fabrics and other surfaces — including DWR and antimicrobial used for face masks and protective gear. In contrast to traditional padding of chemistry onto fabrics, the system uses precision spray technology, significantly reducing chemistry consumption.

The latest generation, TexCoat™ G4, sprays the exact amount of chemistry required consistently and uniformly across the textile surface and applies it only where it is needed — on one or both sides of the fabric.

Since only the necessary amount of chemistry is applied, the wet pick-up levels are reduced by up to 50% compared to conventional finishing methods, leading to 50% decreased water consumption as well as 50% less energy for drying. The low wet pick-up rate together with the single-side spray application can eliminate entire process steps for many fabrics and textiles. TexCoat™ ticks all the sustainability boxes.

“With TexCoat™, there’s no pad to empty, so no waste, and no need to stop for a 30-minute changeover to run the next fabric,” Stanford emphasized. “This saves up to 150 liters of chemistry with each changeover, having a substantial cumulative savings effect on an annual basis, not to mention a significant reduction in wastewater processing.”

Stanford said word of the impact of the DWR demand is already echoing among some of the chemical suppliers and mills with which Baldwin Technology does business.

“A major supplier of DWR told me that the mills he supplies are consuming DWR in 8 to 10 weeks what normally takes one year. He said it would be great for business, if he could only get the chemicals,” according to Stanford. “He believes that the demand will be high – especially for C6 DWRs — for a while because countries across the world don’t want to get caught flat footed without enough PPE.”

Fluorinated (C6) DWR finishes repel water, oil and stains and are used in PPE fabrics, along with their widespread use in apparel, upholstery and automotive textiles, while non-fluorinated (C0) DWR finishes repel only water.

PPE production, including woven, non-woven and knits is consuming such tremendous amounts of DWR that fabric finishers across the industry are sensing a tightening of the supply of these related chemicals.

Among them is a woven mill that does not produce PPE and is scheduled for installation of Baldwin’s TexCoat™ G4 machine in early June. It’s among many that are shifting their water repellent choice in order to satisfy customer requirements as they come back online.

“When I visited this mill recently, they were padding on C0 water repellent instead of C6, which they favor less because cleaning of the pad is more challenging when processing C0,” Stanford commented. “When I asked my contact why they were doing this, he said because it’s getting expensive and hard to get C6, so they’re padding on C0 if the customer does not specify C6 to meet specific oil repellency performance requirements.”

Stanford reiterated that with the increasing demand for DWR, Baldwin’s TexCoat™ G4 is optimally positioned to eliminate the need for fabric finishers to discard expensive chemistry.

“Not only does precision spray assist the finishers with chemistry utilization, but TexCoat™ also contributes with reaching sustainability goals and being an overall good steward of the environment,” Stanford concluded.