Indian textile units are gradually waking up to the need of having full control over the threads used in their processes. This transformation was quite apparent at the recent GARTEX Texprocess India 2022, a comprehensive garment textile machinery expo organized in India.

During the expo, for the first time, Indian textiles units got to know the advantages of digital thread dyeing. And their deep interest is easy to understand, as this new technology is taking the entire textile world in its stride. This need of the hour was satisfied by Twine Solutions.

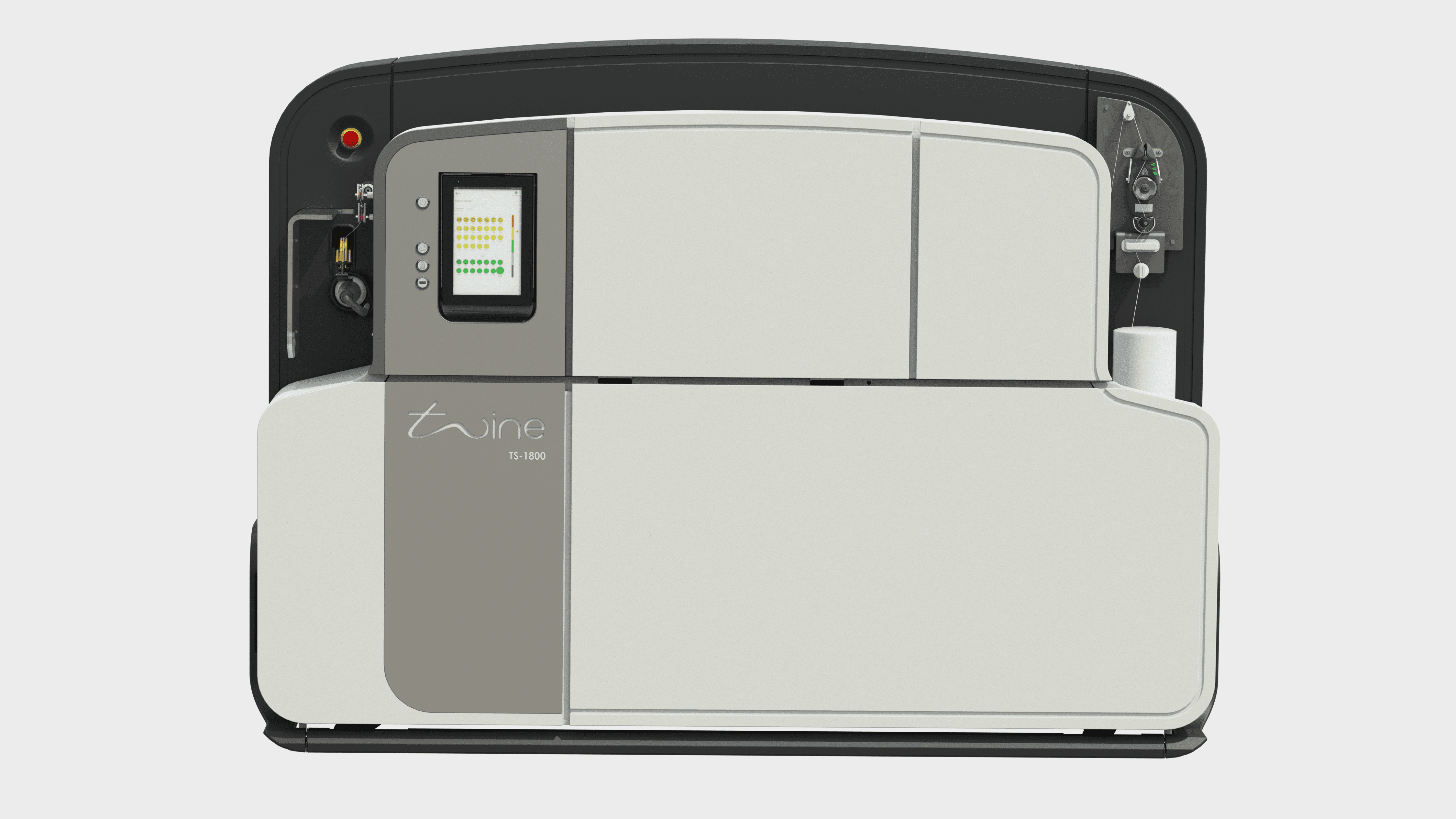

Orange OTec, a Surat, Gujarat based firm presented for the first time an On-demand Thread Dyeing Machine during the expo and it received an overwhelming response from the industry. Orange has teamed with Israel’s Twine Solutions to become a leader in this field. The company provides digital thread dyeing machines on the premises of the knitting, embroidery and sewing facilities.

The plug-and-play machine by Twine uses digital technology to dye thread and can generate any length or color when and where it is required. The threads might have a gradient effect as well. The technology, which also contains high-tech color software, uses waterless dyeing.

The On-demand Thread Dyeing technology by Twine Solutions offers unmatched benefits compared to the conventional method of ordering and stocking thread, without any confirmation of orders. In the conventional method, the units have to invest first in the thread stocks and then try to utilise them. Whereas, Twine technology turns the table completely. Machines developed by Twine prove to be very helpful for needlework and sewing projects.

Rather than ordering complete boxes of spools, the units can now dye the exact lengths of threads required with no minimum order. This helps them to get the exact colors they desire while also reducing inventory. It also saves time and facilitates quick order sampling. The system conserves natural resources and ensures the business’s long-term viability.

Orange OTec also offers a large number of digital textile machines, as well as related accessories. The fast-growing company has been developing novel solutions in response to the growing importance of digital technology in the textile sector. The company has teamed with several well-known foreign corporations to provide Indian businesses with the best in the area.

Leveraging this rich experience, Orange O Tec also provides modern and high-tech printing machines to meet the diverse needs of the Indian sector. The company provides a range of Direct Textile as well as Sublimation Printers to suit a wide range of printing requirements in the marketupto 1500 Linear Meter per day to 11000 Linear Meter per day production capacity. These machines are designed to give the textile sector with amazing new benefits facilitated by digital technologies. Orange O Tec is leading industry to sustainable Digital Textile Printing with 270+ Installation & 2.5 Cr+ Linear Meter company’s installed printers on monthly basis.