GKD – Gebr. Kufferath AG (GKD) will be presenting at FILTECH with a focus on its integrated service range for the world of filtration. The centerpiece of the appearance at the leading trade fair for filtration and separation technology in Cologne will be new and improved high-tech meshes, innovative products, and process belt solutions. The leading international technical weavers will present three highlights in this field: Optimized Dutch Weaves with a woven geometric pore opening of 5 µm, the Porometric mesh range, which is unparalleled worldwide, and the innovative Trimetric filter media made of high-performance filter media laminate for hot gas filtration, boasting temperature resistance up to 600°C. The GKD trade fair appearance will be complemented by a presentation by Dominik Herper, MSc, at the conference that is being held alongside the fair. He will present further possibilities of numerical analyses for the bubble point test for wire meshes.

With its declared focus on solutions that make the world healthier, safer, and cleaner, GKD has prioritized the sustainability of products and processes for years. The company’s contribution to saving resources like water and power are equaled by its efforts to reduce environmental damage through the retention of hazardous substances. What’s more, by using stainless steels that can be recycled at the end of their service life for mesh designs and filter elements, the company reduces plastic waste generated by disposable products. The reusable and regenerable filter media from GKD therefore yield both ecological and economic returns. The owner-managed SME will present current examples of these at FILTECH.

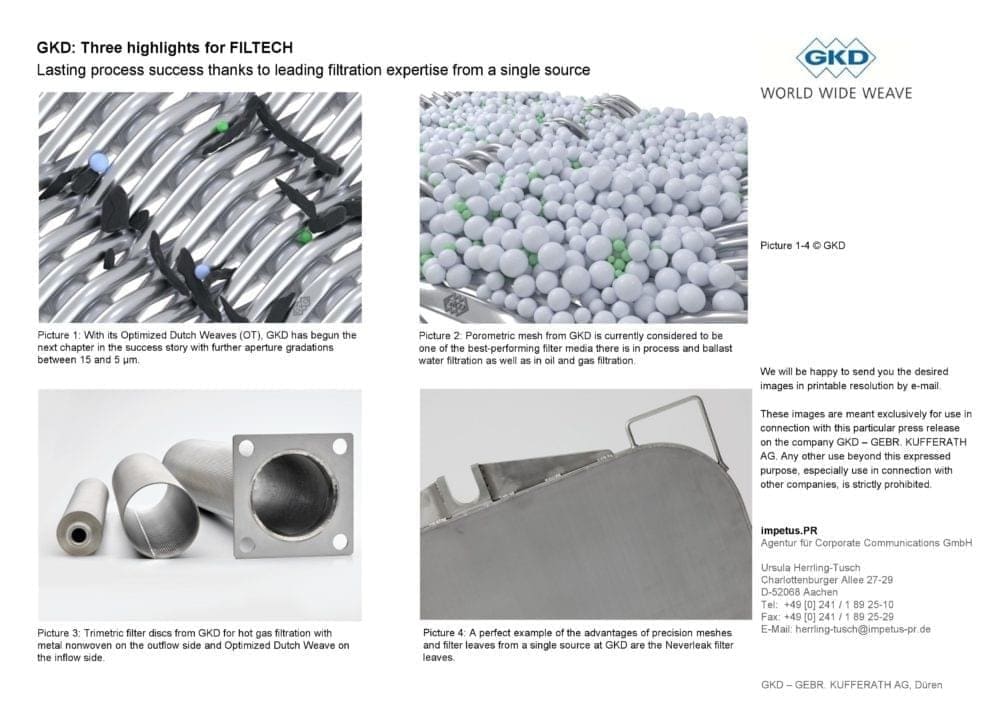

With its Optimized Dutch Weaves (OT), GKD has begun the next chapter in the success story of this range of stainless steel meshes with further aperture gradations between 15 and 5 µm. Slot-shaped pores on the mesh surface and larger pores inside the mesh ensure great dirt holding capacity with very low flow resistance. Particles above the required separating limit are reliably separated at the surface, while smaller ones pass easily through the inner pores. Their low clogging tendency and excellent cleaning properties via backwashing justify the use of Optimized Dutch Weaves in numerous key applications in industry. With the geometric pore size of 5 µm that has now been achieved, the filter medium unparalleled in terms of separation rate and permeability has set a new benchmark in large-scale water processing.

A multi award-winning further development of the Optimized Dutch Weaves is Porometric mesh. It is currently considered to be one of the best-performing filter media there is in process and ballast water filtration as well as in oil and gas filtration. At FILTECH, GKD will be presenting this high-tech mesh with an expanded spectrum of pore openings ranging from 13 to 1,000 µm. The three-dimensional weave with rectangular pores has a designed porosity of over 80 percent. It makes Porometric three times more permeable than conventional meshes. This weave also scores top marks for cleaning with optimum cake release and exceedingly low backwashing rate. Despite the open structure, Porometric mesh is very stable, which significantly increases plant efficiency and the service life of the components. The use of less material for the highly porous mesh is reflected not least in its lower weight and price. In addition, GKD offers the possibility of replacing a component of the mesh design with plastic for special lightweight variants.

The innovative Trimetric filter media laminate will be making its premiere at FILTECH, where it will be presented to the public for the first time. This highly porous, four-ply laminate made of three different stainless steel filter media for hot gas filtration breaks new ground with metal nonwoven on the outflow side and Optimized Dutch Weave on the inflow side. In this way, the innovative filter medium combines retention rates that are otherwise only typical of PTFE filter media with temperature resistance of up to 600°C. The result is that energy-intensive reheating of the gas is no longer required and downstream units are protected. As an inherently stable construction, Trimetric filter media do not require a support basket. Their mechanical stability also enables them to withstand vibrating or pulsing loads. If necessary, they can even be cleaned externally using a high-pressure cleaner. High dirt holding capacity, good cleaning properties, and excellent cake release make Trimetric filter media the problem solver that hot gas filtration has been waiting for. They can be used without alteration in existing cartridge filter systems and with a slight modification of the fastening elements in the filter housing, they can also be employed in existing bag filter systems.

With a broad spectrum of ready-for-installation filter elements, GKD underlines its innovative skill and leading production standards. Whether horizontal pressure leaf filters, filter cartridges, filter discs, or filter segments: filter systems tailored to specific processes all the way up to entire constructions of large filter elements are proof of the company’s extensive manufacturing expertise. A perfect example of the advantages of precision meshes and filter leaves from a single source at GKD are the Neverleak filter leaves for precoat filtration. Unlike old riveted constructions, with original, tightly welded PZ mesh they guarantee reliable sealing of the elements. The base frame can be reused multiple times and rescreened economically. Often, GKD can also help to save on costs by rescreening filter cartridges, frames, and inserts, too. Existing supports and frame constructions are reused and the process efficiency can be increased by using application-optimized filter media.

At FILTECH, the filtration experts will be presenting the range of possibilities available for optimizing existing processes over three days.

Visit

GKD – Gebr. Kufferath AG at

FILTECH

October 22-24, 2019

Kölnmesse

Hall 11.1, G3