Glass hybrid belt for nonwovens processing

A large number of visitors from the sector took the opportunity to discuss current issues with the process belt experts from GKD – Gebr. Kufferath AG (GKD) during the Techtextil fair. They were particularly interested in the anti-stick coating on the glass hybrid belts for use in single-belt and double-belt dryers. However, the metal fabric solutions for filtration processes and architecture, which the leading global manufacturer of application-specific high-performance fabrics presented in Frankfurt, also proved very popular among visitors to the stand.

Indeed, the large-format, movable panels – comprising a very wide range of fabric types in terms of materials, weaves, and colors for industry and architecture – proved to be real eyecatchers that visitors were keen to touch on GKD’s stand at the Techtextil fair. For process belt customers that have been using these belts successfully for many years, a typical GKD blue belt served as a distinguishing feature that could be seen from great distances. The seam samples, which were on show and available for visitors to touch, also motivated prospective clients to strike up a conversation with the engineers from GKD. The discussions regarding innovative process belt solutions focused on the areas of thermobonding, forming and hygiene. The absolute hit among the process belts were the glass hybrid fabric belts with anti-stick coating presented by GKD at the leading international trade fair for technical textiles and nonwovens.

No more sticking

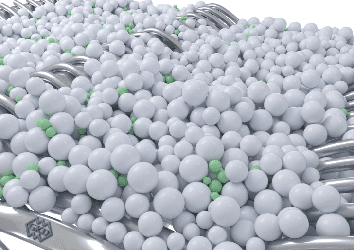

With this belt type, GKD is responding to a pressing problem in the field of web bonding and drying. The new belt combines low weight with transverse

stability thanks to its use of glass strands that are interwoven in the running

direction. Perhaps the belt’s greatest strength, however, is its high-grade

anti-stick coating, which minimizes soiling due to product residues, even

when processing “sticky” products. This belt design, which is unparalleled to

date in the market, significantly improves the entire process thanks to this

characteristic. In addition, the fact that fewer cleaning cycles are required

resulting in less cleaning-based downtime also has a positive impact on

productivity. In comparison with conventional rotary glass belts with PTFE

coating, the glass hybrid fabric belts from GKD guarantee significantly better

process performance thanks to their reliable anti-stick protection and high

degree of transverse stability. There was therefore a great deal of interest in

this novel belt type for thermobonding processes.

Beside many existing customers – that often use the trade fair to maintain

contacts and gather new information – the GKD stand also attracted many

new prospective customers. The large number of contacts and high-level

technical discussions were what ultimately shaped the overall impression of

Michael Seelert, Head of Process Belts: “Our appearance at the Techtextil

event was very successful. In terms of the quality of contacts made, it is even

fair to say it was our best ever.”

GKD – WORLD WIDE WEAVE

As a privately owned technical weaver, GKD – Gebr. Kufferath AG is the

world market leader in metal, synthetic and spiral mesh solutions. Four

independent business divisions bundle their expertise under one roof:

Industrial Mesh (woven metal mesh and filter solutions), Process Belts (belts

made of mesh and spirals), Architectural meshes (façades, safety and

interior design made of metal fabrics) and Mediamesh® (Transparent mediafaçades). With its headquarter in Germany and five other facilities in the US, South Africa, China, India and Chile – as well as its branches in France, Spain, Dubai and worldwide representatives, GKD is close to markets anywhere in the world.

For more information: Please send a reprint to:

GKD – GEBR. KUFFERATH AG impetus.PR

Metallweberstraße 46 Ursula Herrling-Tusch

D-52353 Düren Charlottenburger Allee 27-29

Tel.: +49 (0) 2421 / 803-0 D-52068 Aachen

Fax: +49 (0) 2421 / 803-227 Tel.: +49 (0) 241 / 189 25-10

E-Mail: [email protected] Fax: +49 (0) 241 / 189 25-29

www.gkd.de E-mail: [email protected]

Picture 1: Anti-stick coated glass hybrid belts for use in single-belt and

double-belt dryers combine low weight with transverse stability thanks

to its use of glass strands that are interwoven in the running direction.

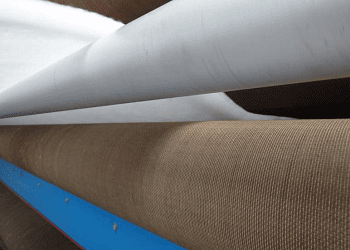

Picture 2: Glass hybrid fabric belts from GKD guarantee significantly

better process performance thanks to their reliable anti-stick protection

and high degree of transverse stability.

Picture 3: Industrial mesh attracted many visitors to the GKD stand.

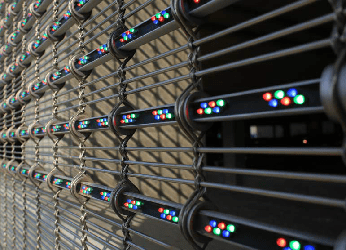

Picture 4: Metal mesh solutions such as the transparent media

façade system Mediamesh with integrated LED profiles attracted

numerous visitors to the GKD stand.

Picture 1-3 © GKD

Picture 4 © GKD /Immotion

We will be happy to send you the desired

images in printable resolution by e-mail.

These images are meant exclusively for use in

connection with this particular press release

on the company GKD – GEBR. KUFFERATH

AG. Any other use beyond this expressed

purpose, especially use in connection with

other companies, is strictly prohibited.

impetus.PR

Agentur für Corporate Communications GmbH

Ursula Herrling-Tusch

Charlottenburger Allee 27-29

D-52068 Aachen

Tel: +49 [0] 241 / 1 89 25-10

Fax: +49 [0] 241 / 1 89 25-29

E-Mail: [email protected]