Far-reaching transformation introduced

In the 2020 financial year, which was marked by the coronavirus pandemic, the global GKD Group once again proved its resilience as a systems and solution provider with a diverse portfolio. As a result of the slump on global markets, the revenue of the global market leader for technical weave for industry and architecture fell by 9.5 percent to 97.2 million euros (2019: 107.4 million euros). Twenty percent of this drop in revenue was attributable to negative currency effects, so the group result for 2020 was only 2.0 million euros below the previous year’s record level. In parallel with this, the family-run company now in its third and fourth generation continued to actively pursue its long term strategic objectives, again setting the course for future growth. As of the balance sheet date, the GKD Group employed 860 people (2019: 848), 461 of them at the headquarters in Düren, Germany (2019: 445).

“We suffered only very little in these unusually turbulent times for the global economy and have shown that we are well established with the right products in the relevant markets,” says Director Dr. Stephan Kufferath. All group locations with the exception of the USA and Düren were affected by complete shutdowns lasting several weeks. Thanks to being recognized as a system-relevant company in the respective states, however, production was able to resume everywhere reasonably quickly. Protective measures and processes established successfully across the group early on guaranteed the required employee security in every phase and ensured that customer needs were met. Nevertheless, all divisions and regions recorded a decline in revenue. The massive effects of the pandemic on the automotive, aerospace, oil and gas, and printing industries led to losses in revenue of

eleven percent in the industrial mesh division. For process belts, too, the group suffered losses of minus ten percent on the previous year’s revenue despite strong growth in belts for the corrugated board, nonwovens, and food industries. In the architectural mesh division, the restructuring of the division over recent years and the renewed strong development of business in the USA (plus 14 percent) showed an impact, with a moderate drop in revenue at group level of minus four percent. GKD USA, however, was worst affected by the fall in demand from the automotive and aviation industries. As such, this largest regional market segment in the GKD Group also suffered a slight drop in revenue (minus two percent). The group suffered the greatest losses in revenue in terms of volume in Europe at minus 12 percent. The key drivers here were the massive effects of the pandemic in southern Europe.

Group-wide training campaign

As was the case in the global economic crisis of 2008/2009, GKD did all it could to avoid operational redundancies and thereby the loss of qualified staff. For this reason well-considered use was made the short-working-hours scheme in Düren. The company has proven its flexibility in the past and this situation provided the opportunity to do so once more: Through targeted staff shifting within the divisions, GKD pushed forward development projects with great drive. Despite a downward trend in revenue, great efforts were invested in further developing the group in 2020: “We used the time during the pandemic to continue working on the development of our long-term business strategy and transformation so that we were able to act with a completely different degree of preparedness around the world once travel restrictions were lifted,” says Dr. Stephan Kufferath. With the introduction of a GKD-wide CRM (Customer Relationship Management) system, an internal communication and collaboration platform called the Infobase, and the development of a group-wide corporate culture, the initial milestones of this transformation were achieved. To do this, GKD also used the strong virtual

presence of its employees caused by the pandemic throughout the group. Intensive training courses at all sites made it possible to introduce the new CRM system and various other pioneering IT systems as well as training courses on the new standardized corporate culture for all sites. Another focus of training throughout the group was IATF 16949 – an internationally recognized quality standard for suppliers of the automotive sector.

Big investments in the future

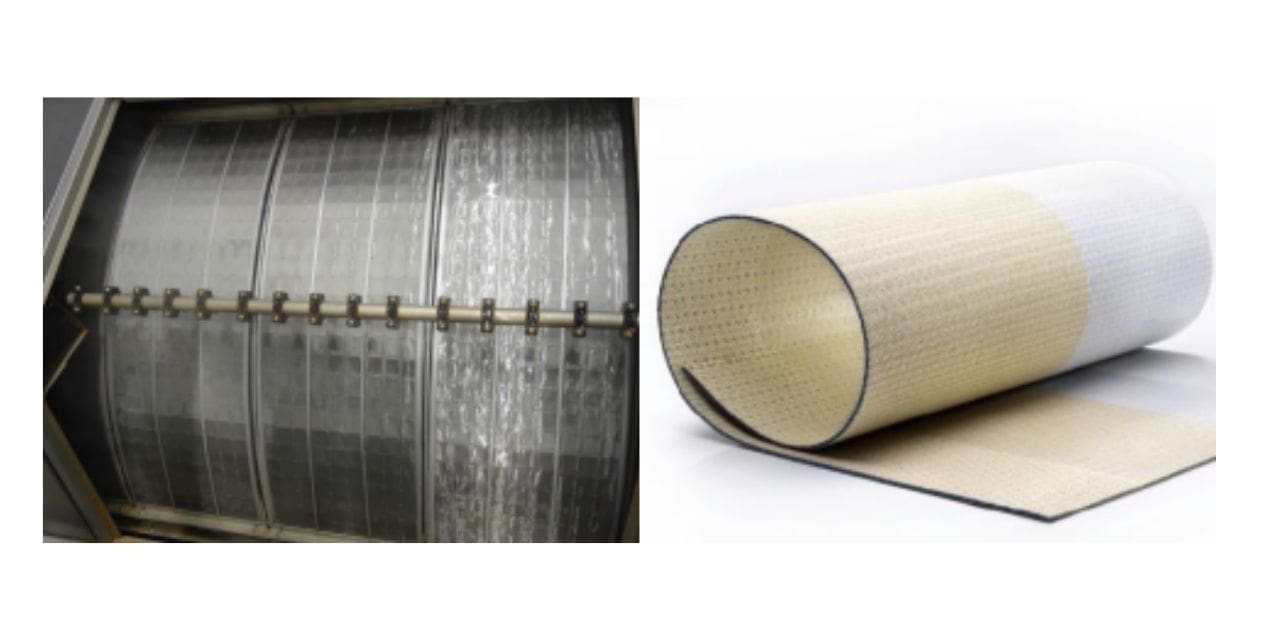

GKD emphasized this course of transformation with investments amounting to 6.7 million euros in machines, systems, IT infrastructure, and the completion of construction projects. “With just a few exceptions, GKD has never made such big investments as it did in 2020,” says Director Ingo Kufferath, emphasizing their importance. He adds: “According to our strategy of helping to make the world healthier, safer, and cleaner, we always make investments in our machine pool with the aim of breaking into new markets with new products and solutions.” Examples of this in the past financial year include a new wide loom for producing new products for the nonwovens and corrugated board industry, a loom for producing special heavy industrial mesh for applications in filtration technology, and further expansion of the micromesh platform with improved fine looms. In addition, the value-added steps of the finishing processes were expanded with new cutting, laser, and rolling technology. As always, investments were not limited to the main factory in Düren, but also benefited the production capacities of all subsidiaries. For example, the loom capacities of GKD India underwent significant expansion, at GKD USA two new manufacturing processes were introduced, and at GKD Chile a loom was converted to manufacture new products. In parallel to this, the digitalization of production on the way to becoming a smart factory, which began several years ago, was advanced further. The aim is to have all looms and finishing machines connected in the next 12 months.

Five-year strategy kicked off

For the current fiscal year, GKD expects a positive sales trend with a positive result. “We believe that we can make up for what we lost in 2020 in 2021, and that at the same time we have created the prerequisites for even more substantial, healthy growth in our focus areas,” says Dr. Stephan Kufferath. In addition, 2021 marks the start of implementation of the five-year transformation and business strategy. With effect from April 1, Lara Kufferath and Markus Kosel were appointed as additional members of the previously two-person Management Board, which was reorganized at the same time. The Management Board is now divided into four divisions with Group-wide responsibility: Dr. Stephan Kufferath (Sales & Marketing), Ingo Kufferath (Technology & Production), Lara Kufferath (Digitalization & Transformation), and Markus Kosel (Finance & Controlling).

“GKD has grown enormously on an international scale in the last few years. We recognized early on that our current structures would reach their limits, particularly as we continue to see major potential for growth in the market,” explains Lara Kufferath, who is chiefly responsible for implementing the long

term transformation strategy. She adds: “This year is the first time that we have created a five-year strategy for the GKD Group and are actively communicating it among the workforce in order to get all employees involved in this process worldwide.” The aim is to eliminate obstacles to growth and to make full use of existing synergies. That’s why international cooperation at all levels and the digitalization of business processes are the key focus in the current fiscal year. “We are convinced that the investments and projects associated with this will lay the foundation for further sustainable growth steps for the GKD Group,” says Lara Kufferath.