Geosynthetic is manufactured from a polymeric material that is used with soil, rock, or other geotechnical-related material. Most geosynthetics are made from synthetic polymers of polypropylene, polyester, or polyethylene. Geo-synthetic products available today include, but are not limited to, Geo-webs, Geo-grids, Geonets, Geomeshes, Geo-composites, and Geo-textiles. Geo-textile is a permeable Geo-synthetic made of textile materials.

Primary advantages of Geosynthetics

- Relatively low cost for many applications

- Ease and convenience for many applications Quick and effective

- rotection against erosion problems

- Design methodologies are available for many uses

- Many variety of geosynthetic products are available to meet specific needs

- May be removed and reused if economically feasible

Limitations

- Effectiveness may be reduced drastically if the Geo-synthetic is not properly selected, designed, or installed.

- Many Geo-synthetics are sensitive to light degradation and must be protected prior to installation. Geo-synthetics that are not degradable should not be used where their presence or appearance is aesthetically unacceptable.

Major applications of Geosynthetics are:

- In Roads and Pavements:

- Subgrade separation and Stabilization,

- Base Reinforcement

- Overlay Stress Absorption and Reinforcement

- Subsurface Drainage:

- Subgrade dewatering,

- Road base drainage,

- Structure drainage

- Erosion and Sediment Control

- Hard Armor Systems, Silt Fence

Reinforced Soil Systems:

- Embankments over soft foundations,

- Reinforced Steepened slopes,

- Reinforced soil walls

- In Seepage control systems

- Structure water proofing,

- Environmental Protection

- In Support Systems

- Prefabricated Systems and On-site Fabrication Roads

GEO TEXTILES USE FOR ACCESS/HAUL ROADS – PARKING LOTS – HIGHWAYS AND STREETS (BASE REINFORCEMENT)

For low cost, geosynthetics can significantly extend the life of everyday structures by preventing the intermixing of subgrade soils and the aggregate base, and/or stabilizing poor subgrades.

- The Slit-Film Woven Geotextiles

Most frequently specified to perform at least one of the following functions:

- Separation

- Stabilization

2. Woven Polypropylene Geotextiles

Most frequently specified to perform at least one of the following functions:

- Reinforcement

- Separation

- Filtration

- Confinement

3. Geo cells

Geocells are most frequently specified to perform at least one of the following functions:

- Containment

- Erosion – Slope Protection

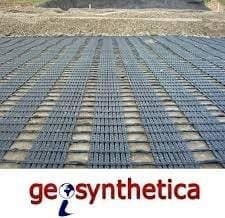

- Geogrids

Rigid Biaxial Polypropylene Geogridsmost frequently specified to perform at least one of the following functions:

- Reinforcement

- Confinement

- Nonwoven Geotextiles

Nonwoven Geotextiles are most frequently specified to perform at least one of the following functions:

- Filtration

- Drainage

- Separation

- Erosion

- Protection

Erosion

GEO TEXTILES USE FOR SHORELINES – SLOPES – SWALES – CHANNELS – CANALS

These were the very first applications of a geotextile way back in 1958. The fabric, which lies beneath various forms of riprap cover (i.e. rock, gabions and mattresses, concrete pattern-placed units, etc.), allows for free drainage of water while holding back fines thereby preventing shoreline and other erosion.

- Woven Monofilament geotextiles

Most frequently specified to perform at least one of the following functions:

- Long-Term Filtration

- Drainage

- Erosion Protection

- Separation

- Woven monofilament geotextiles, woven geo textiles and non-woven geotextiles are also used for prevention of erosion

Drainage

SUBSURFACE DRAINAGE

This is one of the most common applications of geotextiles in the construction of roadways, landfills, athletic fields etc, allowing for rapid removal of water or other fluids while providing excellent soil retention, assuring long-term free flowing drainage.

Woven Monofilament geotextiles and non-woven geotextiles are used for Drainage

Embankments

REINFORCED EMBANKMENTS – STEEPENED SLOPES

Common applications include earth dams, embankments on soft foundation soils, levees, highway embankments, landslide repair, landfills, dikes and levees.

- High-Strength (PET) of Woven Geotextiles

The PET High-Strength Woven Polyester Geotextiles are most frequently specified to perform at least one of the following functions:

- Reinforcement

- Separation

- Confinement

- Woven-Coated Uniaxial Polyester Geogrids

Most frequently specified to perform at least one of the following functions:

- Aggregate Reinforcement

- Soil Reinforcement

- PP woven geo-textiles are also used of reinforcement

SRW Walls

SEGMENTAL RETAINING WALLS

- Woven-Coated Uniaxial Geogrids (Given above) are most frequently used to build SRW wall

- Use of Non-woven geo textiles (Given Above)

- Use of Woven Monofilament geotextiles (Given Above)

Alternative Walls

Cost-effective Mechanically Stabilized Earth (MSE) structures are temporary roadway detours, wrapped faced walls, highway bridge construction

- Use of Geocells – Cellular Confinement System (given above)

- Use of Geogrids – as given above

- Use of Woven-Coated Uniaxial Geogrids(Given above)

- 4.Use of High-Performance Woven Polypropylene Geotextiles (given above)

- Use of PET High-Strength Series of Woven Polyester Geotextiles (given above)

Prefabricated Vertical (PV) drains

Slim, Sleek, Flexible, durable and reliable. Prefabricated Vertical (PV) drains may be light in weight but they deliver a heavy blow to slow-draining soils

These drains are widely used for warehouses, storage tanks, residential and retail structures,

Roadways, airport runways, industrial facilities, port and marine construction, and MSE walls

Pavements

PAVEMENT RESTORATION

Asphalt overlay fabrics can extend the life of all existing paved areas. These specially manufactured nonwoven geotextiles are first saturated with heated liquid asphalt during installation, and creates a moisture barrier between old and new pavement. In addition, they absorb stresses to retard reflective cracking, thereby improving and extending the overall performance of the new overlay

- Asphalt Overlay Fabrics are most frequently specified to perform at least one of the following functions.

- Moisture Sealing

- Stress Relief

- Bonding

- Pavement Interlayer

Environmental

ENVIRONMENTAL – LANDFILLS

Landfill and waste-containment projects utilize a wide variety protection, drainage, steepened slopes, vegetation/erosion control, gas venting and capping/closures.

Woven monofilament textiles, non-woven geotextiles, high performance PP woven goetextiles, high strength PET woven geotextiles and geo-grids are all (given above) used for land fills

Erosion Blankets

EROSION CONTROL BLANKETS – (TEMPORARY) – EROSION APPLICATIONS

Erosion Control Blankets (ECBs) are ideal solutions for the short-term challenges of establishing vegetation in low to moderate erosion applications such as: subtle grades to steep 1:1 slopes; swales; moderate flow channels.

Degradable Erosion Control Blankets are most frequently specified to perform at least one of the following functions:

- Vegetation

- Soil-Seed Retention

Erosion Control Blankets are made up of matrix combinations of straw, wood and/or coconut fibers; with single or double-sided polypropylene or jute netting and provide immediate erosion protection during vegetation in low to moderate erosion control applications.

Turf Reinforcement

TURF REINFORCEMENT MATS – (PERMANENT)

- Turf Reinforcement Mats (TRMs) are for those moderate to severe applications that require both permanent and reinforced vegetation in addition to the immediate needs of preventing surface erosion while establishing vegetation.

Turf Reinforcement Mats are most frequently specified to perform at least one of the following functions:

- Reinforced Turf

- Erosion Control

- Soil-Seed Retention

It is a dense matrix of polypropylene (PP) and/or organic fibers between netting to provide immediate erosion protection during vegetation; and permanent Reinforced Turf and Erosion Control for moderate to high-flow conditions. The materials extend the erosion resistance of soil, rock, and other materials by permanently reinforcing the vegetative root structure.

- Anchor Reinforced Vegetation Systems are most frequently specified to perform at least one of the following functions:

- Erosion Control (Severe)

- Stabilization

- Reinforced Soil

- Reinforced Vegetation

comprised of woven high–tenacity polyester yarns for reinforcement at low strains; entangled within a three dimensional matrix of continuous nylon monofilaments fused at their intersections. When anchored with the S2 aluminum alloy percussion driven anchors to compressed soils 24″–36″ beneath the surface

Landscape

LANDSCAPE – GROUND COVER FABRICS

Landscape fabrics come in a variety of weights and types. Their primary functions are separation and friction, weed block, moisture retention, patio/paver underlayment, and drainage filter fabric

.1. Landscape and Ground Cover fabrics are used for:

- Retarding Weed Growth

- Reducing Evaporation

- Plant Alignment

- Pedestrian Traffic Areas (WC Landscape Series)

Retention of Mulch and Reduction of Erosion on Embankments

- Patio and Paver Underlayment

- Drainage

These fabrics are woven polypropylene geotextiles with polypropylene fibers needle-punched into them. This process helps prevent bark and mulch from sliding off the fabric and makes them ideal to use on any sloped area that needs to be covered. In addition, they contain colored marker yarns every 12 inches. Treated with a special UV protection, they are designed to last approximately 10 years in sunlight and indefinitely in the shade. They are resistant to insects and rodents and will not rot or support mildew.

.2. High UV Groundcover fabric

Fabrics are woven polypropylene geotextiles with colored marker yarns every 12 inches for quick and easy plant alignment and presentation. Treated with a special UV protection, they are designed to last approximately 10 years in sunlight and indefinitely in the shade. Puncture and tear resistant, they sustain pedestrian and light vehicle traffic. They are resistant to insects and rodents and will not rot or support mildew.

.3. Spunbond landscape fabrics

Nonwoven landscape fabrics are spunbond, 100% polyester (PET) geotextiles. With their high strength to weight ratios, the LX-SB landscape fabrics provide excellent dimensional stability. The polyester construction of the LX-SB Series is non-biodegradable, is rot and mildew resistant and offer excellent ultra-violet resistance insuring its long life. Ideal to use as a weed block, an underlayment for patio and paver applications, and as a drainage filter fabric.

ATIRA has the Centre of Excellence (CoE) for Geo-textiles with state of the art facilities for testing. ATIRA is actively involved in the Promotion of usage of Geotextiles in North Eastern Region of India