This year marks Monforts’ 140th anniversary, & the company is still in the forefront of finishing & coating innovations for technical textiles. At the upcoming Techtextil show in Frankfurt, Germany, from April 23–26, the firm looks forward to many productive conversations about the scope of current and new processes and applications.

The European-built Montex stenters from Monfort have gained their reputation as the industry leaders in fabric finishing for technical textiles because of their durability, adaptability, economy, and ecology.

Numerous companies that produce automobile fabrics, spacer fabrics, flame-retardant barrier fabrics, and geotextiles are among the current clients. Dedicated Montex lines have also been offered to companies that make airbags.

Wovens, knits & nonwovens

Recently, Dickson-Constant installed a custom Montex line at its second plant in northern France to meet the growing demand for its line of well-known sun protection and outdoor upholstery fabrics. Meanwhile, Albarrie in Ontario, Canada, is receiving a line supplied to it that treats specialized needle punched nonwovens up to 4mm thick for filter media and performance fabrics.

Germany continues to hold the top spot in Europe for producing technical textiles, and GTA in Neresheim is currently using three wide-width Montex lines to produce fault-free substrates for the digital printing market that are based on warp knits made of 100% polyester.

According to GTA Managing Director Andreas Niess, “I have to say that the Monforts after-service has been absolutely perfect and there has been no shortage of quality, expertise and service on which we have drawn.”

Recently, Knopf’s Sohn, a prominent contract finisher of technical textiles for the home furnishings, workwear, automotive, and aerospace industries, introduced a fully automated Montex stenter at its Helmbrechts facility.

Meanwhile, Dolinschek in Baden-Württemberg produces a wide range of technical goods, such as wallcoverings, geotextiles, and automotive parts, in addition to items for more peculiar uses like extractor hood inlays, cut protection fabrics, and even wool felts used as wind turbine insulation. Dolinschek has created and launched its own line of exclusive dying equipment.

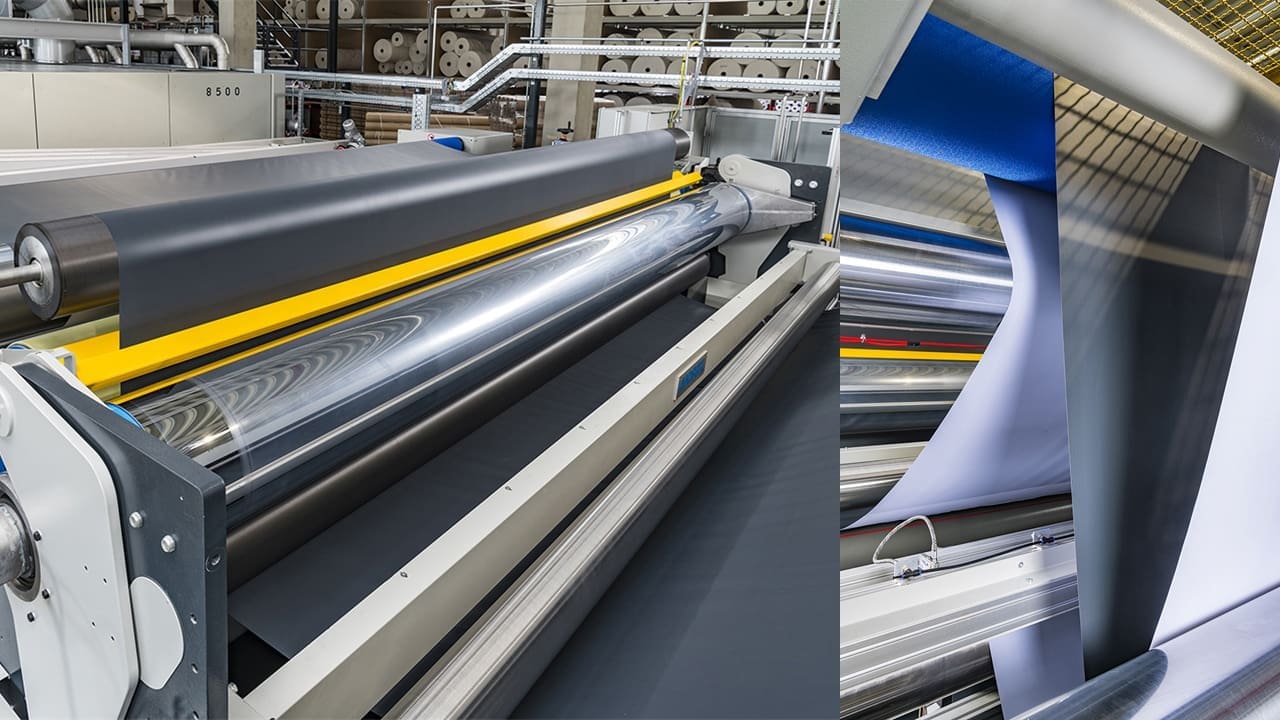

Montex®Coat

Dolinschek has also installed a Montex®Coat coating unit in knife execution, enabling the coating of dimensionally stable knitted fabrics with polyurethane or acrylate.

The Montex®Coat enables full PVC coatings, pigment dyeing or minimal application surface and low penetration treatments, as well as solvent coatings to be carried out. Its key technical applications include tents, tarpaulins and awnings, black-out roller blinds and sail cloth, automotive interior fabrics and medical disposables.

Other recent Montex®Coat installations include a unit for providing an anti-slip and textured backing to upholstery fabrics with a stable and uniform foam via knife-over-roller coating at Altun Tekstil in Bursa, Turkey, and a combined Montex®Coat and Montex stenter range for Scottish weatherproofing specialist Halley Stevensons at its plant in Dundee.

“The precise process control functions of the Monforts line give our technicians the confidence to make new products as well as finely tuning the energy requirements of existing products,” says Halley Stevensons Managing Director James Campbell. “We love the fact that we can record the energy used on each production batch and use this for continual improvements and efficiency savings. The touchscreen software is visual and easy to use, moving from one screen to another to check the various parameters of processing.”

Glimpse of the future

“It’s the sheer diversity of applications for technical fabrics that makes Techtextil always such an exciting show for us,” says Monforts marketing manager Nicole Croonenbroek. “You really get a glimpse of the future and there are always growing opportunities in a number of rapidly expanding markets, such as the current need for new energy storage and transportation, for example, or the electrification of vehicles, where advanced materials can solve newly-arising challenges. At Techtextil 2024 we will be exhibiting a further new development for advanced coating about which we’ll be providing further details shortly.”

Monforts is at stand C58 in Hall 12.0 at Techtextil 2024.