The debut of its enhanced lyocell shortcut fibres by VEOCELTM for the flushable market has been announced by Lenzing Group, a leading global manufacturer of wood-based speciality fibres. In addition to having great dispersibility, which makes them perfect for use in flushable wipes, the updated lyocell shortcut fibres also have an improved finish, which is a bonus for wipes manufacturers. The improved finish helps to produce goods of higher quality and improves the processability of fibres used in the creation of wipes. The fibres are also promoted as being carbon neutral1, which supports efforts made around the world to lessen the carbon footprint of business. Always coming up with new ideas to raise the standard of the fibres

We always seek out new opportunities to innovate and enhance the functionality of our fibres in the flushable Claudio Zampino, Commercial Director of Specialty Applications for Lenzing’s Global Nonwovens Business, stated that the market. “As we promote innovation in the nonwovens industry, it is crucial to have ongoing conversations with value chain partners to meet their requirements and difficulties. Having produced lyocell shortcut fibres for 27 years, we will maintain utilising our large research labs to provide consumers with the most quality lyocell shortcut fibres we can.

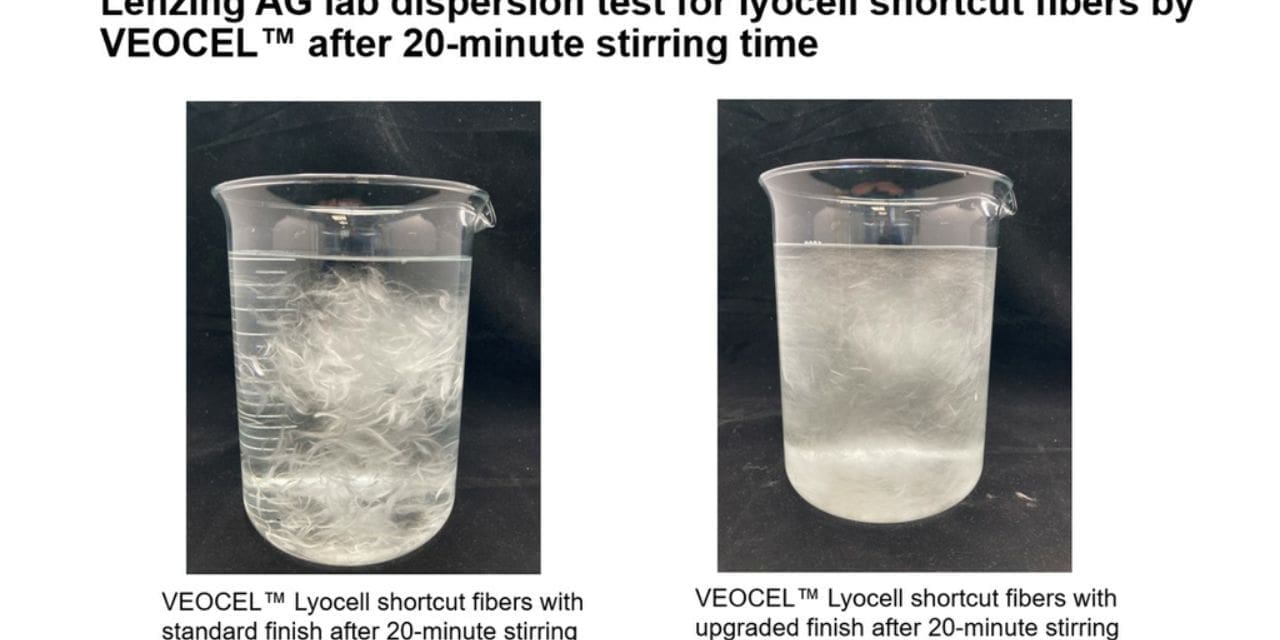

In the wetlaid manufacturing process, the enhanced finish of the updated lyocell shortcut fibres provides defence against mechanical stress at regularly used water temperatures like 0°C to 40°C. This aids in preventing the formation of fibre lumps when fibres are opened and diluted in preparation tanks. The final item will also have improved physical properties. thanks to the improved finish, which enhances web creation throughout the process, quality and beauty. The innovative lyocell shortcut fibres were employed by Albaad, one of the biggest wet wipe producers in the world, to create Hydrofine®, the most commercially successful flushable wetlaid in Europe.

“We are honoured to work with the Lenzing Group globally to develop advancements for lyocell fibres and to introduce fresh ideas that improve our Hydrofine® product and the manufacturing process. Based on these improved fibres, our distinctive Hydrofine product—which is widely regarded as a breakthrough in the flushable market—helps to boost production effectiveness, lower waste levels, and boost customer happiness. Working with the R&D team at Lenzing was a rewarding experience that taught both parties a lot. Albaad is faithful. According to Albaad CEO Jacob Heen, the company is committed to innovation, lowering its carbon impact and improving the performance of its goods.

Market expansion for flushables will continue.

For better convenience and a less environmental impact, customers are utilising flushable wipes more frequently. 2.1 million tonnes, valued at $29.0 billion, are anticipated to be consumed by the worldwide nonwoven wipes market in 2072, up from 1.5 million tonnes, valued at $20.8 billion, in 2022. It is crucial to distinguish between flushable wipes made of wood-based fibres and wipes made of fossil-based fibres, such as polyester or polypropylene, which take decades to decompose and add to the problem of microplastics in the world, as consumers continue to seek out products made of natural materials.

Flushable According to mechanical and biological tests conducted at the Lenzing R&D Center and the International Water Services Flushability Group (IWSFG) specifications, wipes made of lyocell shortcut fibres by VEOCEL with improved finishes and produced under the proper conditions of the Roll Good Manufacturer can disperse and degrade to meet current flushability guidelines.

Lenzing’s manufacturing facility in Mobile, Alabama sells the upgraded carbon neutral lyocell shortcut fibres made by VEOCEL.