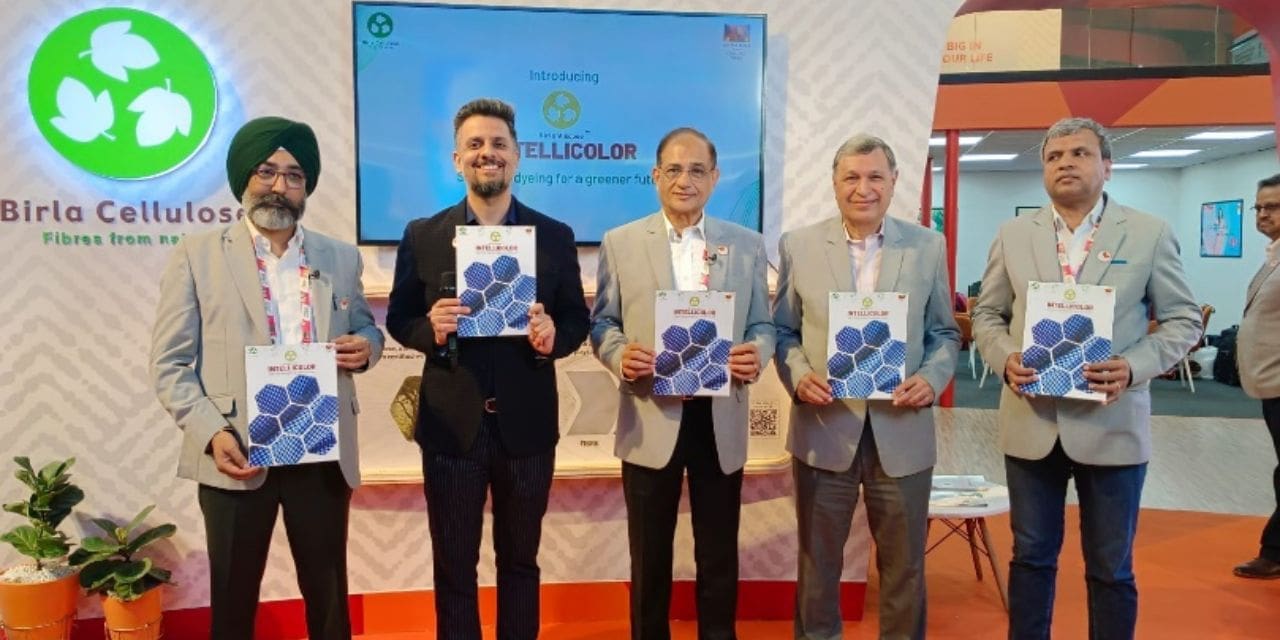

28th February, 2024, Delhi – In a revolutionary move, Birla Cellulose has unveiled its latest innovation, Birla Viscose – Intellicolor, at the prestigious Bharat Tex event. Birla Cellulose is poised to redefine the landscape of the textile industry with its patented product, addressing a long-standing challenge with conventional reactive dyeing.

Intellicolor represents a groundbreaking advancement in the dyeing process, using Cationic or Basic dyes. It boasts a remarkable dye exhaustion rate exceeding 95%, surpassing conventional methods. It eliminates the need for salt and soda ash in the dyeing process, streamlining operations and reducing environmental impact. By achieving brighter shades with higher tinctorial value and color depth compared to reactive dyes, it offers superior color vibrancy while using lower dye concentrations. This results in reduced chemical consumption, lower utility usage, shorter processing times, and decreased dye quantities required, thereby promoting sustainability in dyeing practices.

In conventional or traditional reactive dyeing processes, the use of reactive dyes often necessitates the addition of large quantities of salt to the dye bath. This is primarily due to lower dye bath exhaustion, which results in inadequate dye fixation onto the fabric. As a consequence, high salt concentrations are required to facilitate the dyeing process, leading to significant levels of both salt and unreacted dye being discharged as the effluent. The presence of excessive salt and unreacted dye in the effluent not only poses environmental concerns but also adds to the costs associated with effluent treatment. Intellicolor, aims to usher in a new era by introducing an innovative solution that not only overcomes this challenge but also enhances the overall quality of dyed fabrics.

Moreover, Intellicolor facilitates a more sustainable approach to dyeing by necessitating fewer washes post-dyeing and eliminating fixing steps. This not only conserves water but also reduces energy consumption and ETP operating cost thus leading to huge savings on the utility consumption. It marks a significant advancement by enabling dyeing with Basic dyes, promising enhanced dye uptake and superior wash fastness compared to traditional Reactive dyes.

Speaking on this ground-breaking achievement, the Chief Marketing Officer (CMO) of Grasim Industries, Pulp & Fibre Division, Mr. ManMohan Singh expressed pride in the company’s commitment to innovation. “This is a proud moment for Birla Cellulose as Birla Viscose Intellicolor marks the first of its kind in our ongoing pursuit of excellence. Our commitment to pushing the boundaries of what is possible in textile manufacturing has led to this remarkable innovation,” the CMO stated.

Further, the MD of Grasim Industries, Mr H.K Agarwal, stated, “Today, we mark not just a milestone in innovation, but a commitment to sustainability. Birla Viscose Intellicolor heralds a new era of vibrancy and responsibility in the textile industry, where innovation meets environmental consciousness. At Birla Cellulose, we weave sustainability into every thread of our operations, ensuring a brighter, more sustainable future for textiles.”

The launch of Intellicolor at Bharat Tex signifies a monumental moment in the textile industry and promises reduction in water & energy. This fibre not only meets the immediate needs of the industry but also aligns with the sustainability goals of leading brands, marking a significant step towards a more environmentally conscious and vibrant future for the textile sector.

About Birla Cellulose

Birla Cellulose, the pulp and fibre business of the Aditya Birla Group, is a leading sustainability-focused Man-Made Cellulosic fibre (MMCF) producer.

Birla Cellulose operates multiple pulp and fibre manufacturing sites that apply environmentally efficient technologies. Birla Cellulose tops the Hot Button Ranking and has been accorded a ‘dark green shirt’ by the Canopy Planet Society. Its global advanced research centres are equipped with state-of-the-art facilities and pilot plants. Birla Cellulose’s fibres are made from renewable wood. They are produced using a closed-loop process with significantly lower carbon emissions and lower resource consumption.

Birla Cellulose’s fibres, such as Livaeco viscose, Livaeco Modal, Excel™ (lyocell), and Spunshades™ Enhanced, are manufactured with accredited sustainability benchmarks and deliver superior performance. Liva Reviva is a circular viscose fibre made using cotton waste. It provides a solution to recycle fashion industry waste into fresh fibres. Birla Cellulose collaborates actively with its upstream and downstream partners with an aim to create a more extensive positive impact on the sustainability of its value chain.