The textile industry is no stranger to innovation, continuously seeking ways to improve efficiency, creativity, and sustainability. Among the latest technological breakthroughs, 3D digital fabric material creation stands out as a game-changer that has revolutionized the textile landscape. This cutting-edge process empowers textile manufacturers and designers to create highly realistic virtual fabric materials, offering a plethora of advantages that directly impact business growth.

Expanded Product Offerings

With digital fabrics, textile businesses can expand their product offerings without the need for significant physical inventory. The ability to showcase a wide range of virtual fabric options and the commercial data of each fabric with a digital library enables the creation of diverse collections and personalized products, catering to a broader customer base and capturing new market segments.

Access to Global Markets

Embracing digital fabrics opens up opportunities to cater to global markets. With virtual fabric samples and online digital libraries, textile businesses can reach a broader audience without geographical limitations. This expanded market reach can lead to increased sales and revenue streams, fostering international business growth.

Reducing Costs and Saving Time

Traditional textile material creation and sampling processes are often laborious and resource-intensive. However, with 3D digital fabric material creation, the need for physical prototypes is eliminated. This reduction in physical sampling not only minimizes raw material waste but also significantly lowers production costs.

By virtually visualizing fabric swatches and material combinations, textile manufacturers can make informed decisions early in the design phase, mitigating the risk of expensive modifications during later stages of production. As a result, the technology saves both time and money, providing textile businesses with improved cost-efficiency and enhanced profit margins.

Embracing Sustainable Practices

Sustainability has emerged as a driving force in today’s textile industry, with brands and consumers increasingly seeking eco-friendly products. Embracing 3D digital fabric material creation aligns with this growing demand for sustainability. By reducing the reliance on physical samples, textile manufacturers actively contribute to minimizing fabric waste and conserving valuable natural resources.

Promoting sustainable practices not only strengthens a textile company’s reputation but also appeals to environmentally conscious brands and consumers, creating new opportunities for growth. As the industry shifts towards more sustainable approaches, businesses that adopt 3D digital fabric material creation can position themselves as leaders in responsible textile manufacturing.

Strengthening Collaboration and Supply Chain Efficiency

In the textile industry, collaboration and supply chain efficiency are essential for seamless operations. 3D digital fabric material creation facilitates real-time sharing of virtual fabric samples and designs between designers, manufacturers, and suppliers, regardless of their geographic locations.

Improved collaboration ensures that everyone involved in the production process has a clear understanding of the design intent, minimizing errors and discrepancies. The result is a more streamlined supply chain with reduced lead times, enabling textile manufacturers to seize market opportunities swiftly and drive business growth.

Introducing Frontier.cool: A Fabric Digitization & Real-time Collaboration Platform — Powered by AI

Frontier.cool provides the world’s first AI-powered fabric digitization & real-time collaboration platform, helping suppliers, manufacturers, and designers digitize their fabrics at scale within just 5 minutes — saving time and money throughout the entire fabric digitization journey.

Already trusted by hundreds of APAC suppliers and vendors, world-renowned fashion brands, and global designers, Frontier.cool enables anyone to digitize fabric materials using a regular flatbed scanner by themselves. Scanning can be performed by the user on-site, eliminating the wastage of time, money, resources, effort, and shipping.

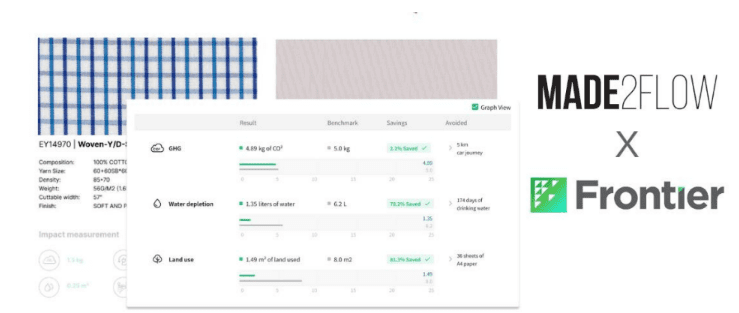

Frontier.cool’s cutting-edge AI and machine learning technology transforms a fabric image into a digital material which includes:

● The fabric specifications.

● AI-generated metadata (or maps) to ensure the digital material looks realistic.

● The material’s physical properties which enable the digital material to move naturally when placed on a 3D model.

● Environmental impact data and much, much more.

Once the digital material has been generated, suppliers can showcase their materials digitally, making it easy for brands to choose fabrics.

Brands and their designers can select fabric and plan collections in real-time — with team members involved — to reduce the cost and time associated with traditional fabric shipping processes. The release of new product lines can be executed in a fraction of the time.

Sustainability Matters

As sustainability takes center stage, transparency becomes paramount for brands. Meeting the demands of regulators, investors, and customers means enhancing traceability throughout the supply chain. Unfortunately, the lack of readily available, scientifically-backed data has hindered brands from achieving their sustainability goals.

Enter Frontier.cool — the world’s first material digitization solution to provide internationally verified environmental impact data estimations. Say goodbye to uncertainties, as Frontier.cool’s cutting-edge technology now enables the delivery of material-level impact measurements with utmost accuracy. From CO2 emissions to water consumption and even land use, the environmental impact data is not just comprehensive but also entirely trust worthy.

Every piece of fabric scanned and uploaded to Frontier.cool’s TextileCloudTM platform displays the estimated impact that it has had on the environment. This information is crucial for informed decision-making right from the very start.

The Bottom Line

As the textile industry evolves, businesses that embrace 3D digital fabric material creation can gain a competitive advantage, cater to changing buyer preferences, and fuel business growth in an ever-competitive market.

Join us in embracing this transformative technology and take the lead in driving sustainable change. Together, we can create a world where fashion meets responsibility — let’s shape a brighter and greener future for the textile industry.

Visit www.frontier.cool for more information or get in touch at [email protected] to schedule a demo.