STUDIES ON FABRICS PRODUCED FROM MODIFIED VISCOSE/BAMBOO YARNS

Prof. (Dr). P.V. Kadole, Prof. S.S. Lavate, Mr. Sonal Ukey*, Mr. Ashish Hulle

Department of Textiles

D.K.T.E. Society’s Textile and Engineering Institute, “Rajwada”, Ichalkaranji-416115 Maharashtra, India

Email*: sonalukey@rocketmail.com

Abstract

In this research work an attempt has been made to study the physical, mechanical and comfort related properties of fabrics made from yarns along with 100 % regular viscose, modified viscose i.e. modal, tencel, excel and bamboo yarns. All above spun yarns were having the same count of 40S Ne (14.76 Tex). Using all these yarns five different plain woven fabrics were manufactured with same yarn in warp as well as in weft. From the study it was found that Tencel fabric is having better characteristics in terms of tensile, thermal, water vapour and air management, surface and dimensional properties whereas viscose is at lower side.

Keywords: viscose, modal, tencel, excel, bamboo

1 Introduction

The rayon is the generic term for all regenerated cellulosic fibers. These fibers generally perform well in producing breathable textiles having softer feel and are comfortable to skin than synthetics which is more important for the fabric to be chosen for clothing. The viscose rayon is the first regenerated cellulosic fiber produced in filament form has a serrated cross section and having low dry strength. To overcome this problem high wet modulus and high tenacity rayons were developed. These fibres were manufactured by dry jet wet spinning process. Due to the changes in the manufacturing process the fiber obtained are having different characteristics and has smoother surface than that of regular viscose rayon.

To fulfill the demand for today’s global world, the modern textiles proposed biodegradable, environment-friendly, and cost-effective fibres like modified cellulosic rayon’s and bamboo fibres. Popular modified variants of viscose rayon are Modal, Tencel, and Excel. Where Modal is 2nd generation, Tencel, Excel and Bamboo are the 3rd generation fibers and viscose rayon is the 1st generation fibre. All are called regenerated cellulosic fibers, since the natural material that makes up the fiber is cellulose. Viscose rayon originated by the wood pulp from a number of different trees like pine, spruce, or hemlock trees and cotton linters, bamboo originating from bamboo tree, modal originating from beech tree, tencel fiber originating from eucalyptus tree are made of cellulose wood. Bamboo fiber has unique properties such as natural antibacterial and antifungal properties, making clothes made from bamboo fibers hygienic, providing smoothness and bamboo fabrics to be non-irritating for sensitive skin. Modified viscose fibers has good hydrophilicity, permeability and its wearing comfort is much better than polyester, its feel, gloss, drape is all good and also has advantages such as dimensional stability and it can be blended with other natural fiber and synthetic fiber. The modified regenerated cellulosic fibers that have promising future are considered for research and development to suit various textile applications. Modified viscose fibers are included in the group of high comfort fibers.

2 Materials and Methods

In this study, commercially available of 100 % viscose, modified viscose i.e. modal, tencel, excel and bamboo spun yarns having same count of 40S Ne (14.76 Tex) were used for fabric manufacturing. By using all these five yarns plain woven fabric with 83 EPI and 68 PPI was manufactured with same yarn in warp and weft. 100 % viscose, modal, tencel, excel and bamboo fabric samples were manufactured on sample weaving machine with single head rigid rapier weft insertion system. After manufacturing of fabric, all the fabric samples were characterized for different properties and results were analyzed by using statistical tools.

3 Results and Discussions

3.1 Yarn characteristics

Before going for actual fabric manufacturing all the yarns were tested for different properties which are as shown in table 3.1.

Table No. 3.1: Yarn characteristics

| Material | Tenacity (gf/tex) | Elongation (%) | Lea Strength (lbs) | U (%) | Imperfections | Hairiness (S3) | Yarn Shrinkage (%) |

| Viscose | 12.69 | 36.89 | 54.20 | 10.39 | 68.80 | 496.20 | 1.67 |

| Modal | 19.14 | 41.12 | 80.70 | 8.92 | 37.60 | 139.60 | 0.67 |

| Tencel | 23.36 | 41.00 | 98.10 | 9.61 | 38.00 | 280.80 | 0.61 |

| Excel | 20.11 | 35.32 | 86.50 | 11.12 | 102.80 | 264.00 | 0.84 |

| Bamboo | 13.84 | 55.07 | 56.00 | 9.99 | 37.40 | 307.80 | 2.02 |

3.2 Fabric Characteristics

3.2.1 Areal Density

Areal density of fabrics woven from different yarns is as shown in fig. 3.1. It can be seen form figure 3.1 that the viscose fabric having lower weight per unit area as compared to all other fabrics. This is due to the fact that pick density of viscose fabric is lower as compare to other fabric samples. Also this may be due to viscose fabric shows lower cover factor of all other fabric samples. Statistical analysis shows there is significant difference between GSM of all the fabric samples.

3.2.2 Thickness

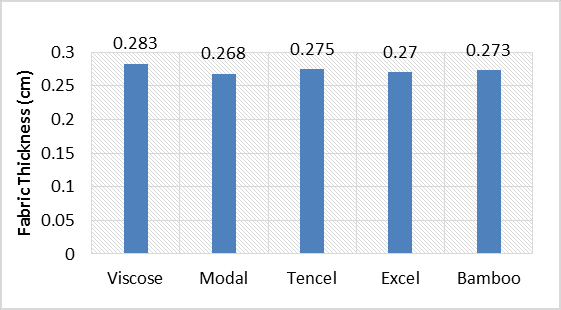

Thickness of fabrics woven from different yarns is as shown in fig. 3.2. From figure 3.2 it can be clearly seen that the all the fabric samples have approximately same thickness value. There are two reasons behind this, first one is all fabrics produced with same count i.e. 40s as well as with similar thread density. Also it was found that the yarn diameter for all yarns is nearly same. Statistical analysis shows that there is no significant difference between the thickness values of all the fabric samples.

Figure 3.2: Thickness

3.2.3 Strength and Elongation

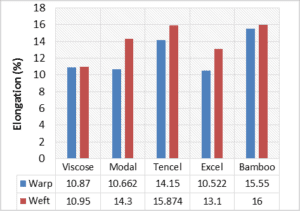

Breaking load and elongation at break of fabrics woven from different yarns is as shown in fig. 3.3 and fig. 3.4 respectively. From the above fig. 3.3 it can be seen that the modified viscose fabrics i.e. modal, tencel and excel are having higher fabric strength in both warp & weft way direction as compare to viscose and bamboo fabrics. This is because of the modified viscose fibers having more crystallinity percentage and also higher degree of polymerization than viscose and bamboo fibres. From the above graph it can also be seen that the tencel fabric gives higher fabric strength in warp as well as in weft direction this is due to tencel fiber has more crystallinity percentage, higher degree of polymerization and a higher molecular orientation than others. When the tencel fibre structure is subjected to mechanical action, the outer crystalline region can break and peel away from the main fibre but remains attached like banana peel. The ratio of crystalline to amorphous area is approximately 9:1, while the values for regular viscose fibre is 6:1 [4].

Figure 3.3: Fabric Strength

Figure 3.4: Fabric Elongation

Fig. 3.4 it can be observed that the elongation percentage at break of bamboo fabric is higher than other fabrics in both warp and weft directions. This may be attributed by higher elongation percentage of bamboo yarn than others. Statistical analysis shows there is significant difference in strength and elongation properties of fabric samples for both warp & weft directions.

3.2.4 Abrasion Resistance

Abrasion resistance of fabrics woven from different yarns is as shown in fig. 3.5. From above figure it is found that the regular viscose rayon fabric has higher weight loss% due to abrasion as compared to modified viscose rayon and bamboo fabrics.

Figure 3.5: Abrasion Resistance

Whereas modified viscose rayon fabrics having lower weight loss% due to abrasion than regular viscose and bamboo fabrics. However, tencel fabric has minimum weight loss% due to abrasion as compared to modal and excel fabrics. Investigation shows that it would be due to the highest tensile strength of modified viscose fibres against viscose and bamboo fibres which makes it to be more durable during abrasion test, also the modified viscose fibres having better frictional characteristics as compared to viscose and bamboo fibres, which may be attributed due to the smooth surface of the modified viscose fibres [11]. Tencel fabric has excellent resistance to abrasion because of higher tensile strength and smooth fibre surface as compare to others. Statistical analysis shows significant difference between all plain woven fabric samples for abrasion resistance

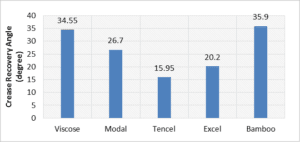

3.2.5 Total Crease Recovery Angle

Crease recovery angle of fabrics woven from different yarns is as shown in fig. 3.6. From fig.3.6 shows total crease recovery angles of fabrics for both warp and weft directions. From above fig. it can be observed that the viscose and bamboo fabrics existed more total crease recovery angle than modified viscose fabrics. However, tencel fabric having lower total CRA this is due to the tencel fabric having smooth surface due to the structure of tencel fibre has a smooth uniform surface and a circular cross section than other fibers. E. R. Kaswell [9] had examined that this is because of fiber cross sectional shape, modified viscose fibers having circular fiber cross section whereas viscose and bamboo have serrated fiber cross sections.

Figure 3.6: Total Crease Recovery Angle

The actual shape of fiber cross section is an uncertain factor, although from a mechanical view point it is probable that a fiber with a circular cross section will resist wrinkle formation better than flat or ribbon like fiber shape. The flat or serrated cross section fiber is more easily bent than circular cross section fiber but once a creased is formed in circular or smooth cross section fiber greater strains are probably developed. Statistical analysis shows significant difference between all samples of crease recovery angle for both warp & weft way.

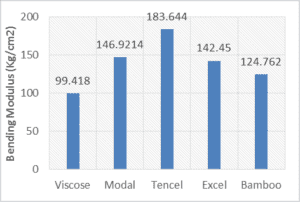

3.2.6 Bending Modulus and Drape Coefficient

Bending modulus and drape coefficient at break of fabrics woven from different yarns is as shown in fig. 3.7 and fig. 3.8 respectively. From above figure 3.7 it can be clearly seen that the modified viscose fabrics have higher bending modulus as compare to viscose & bamboo. This is due to higher stiffness of modified viscose fibers than others. Tencel fabric is stiffer than others. Also modified viscose fibers have a smoother and suppler surface than viscose and bamboo fibers [9].

Figure 3.7: Bending Modulus (Kg/cm2)

Figure 3.8: Drape Coefficient (%)

There is significant difference between bending modulus of all the fabric samples. Fig. 3.8 shows that the modified viscose fabrics having higher drape coefficient than viscose & bamboo. This is due to modified viscose fabrics having higher bending modulus as shown in fig. 3.7 compared to viscose & bamboo. So we can clearly say that the high value of tencel for drape coefficient means that fabric is stiffer than others. Statistical analysis shows significant difference between drape coefficient values of all the fabric samples.

3.2.7 Dimensional Stability

Dimensional stability of fabrics woven from different yarns is as shown in fig. 3.9. Fig. 3.9 shows that the modified viscose fabrics have excellent dimensional stability in both directions i.e. warp and weft than viscose and bamboo fabrics. This is due to the fact that the modified viscose fibres falls under the category of high wet modulus fibers and this leads to a very low shrinkage in water. These fibers have low linear swelling in water, absorb less moisture, more stiffness.

Figure 3.9: Dimensional Stability

Of all fabric samples, tencel has excellent stability than others which is expected, this is because of tencel is stiffer than others. The high elongation value of bamboo fibre can result in high fabric shrinkage [10]. Statistical analysis shows there is significant difference in dimensional stability of all fabric samples both warp & weft way.

3.2.8 Air Permeability

From fig.3.10 it can be observed that the viscose fabric has higher air permeability value compared to others. The reason behind this is the lower pick density as discussed earlier. The ppi of viscose fabric is lower as compared to other fabrics. This would be the pick density effects on air permeability. The pick density decreases, air permeability of fabric will increase. This is due to the air gaps between the constituent yarns after interlacement will increase which ultimately increasing air permeability of fabric [5, 8, 9]. Statistical analysis shows that there is significant difference between air permeability values of all fabric samples.

Figure 3.10: Air Permeability

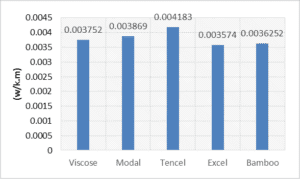

3.2.9 Thermal Conductivity

The fig.3.11 shows that the tencel fabric having higher thermal conductivity compared to others. This is because of tencel fabric having smooth surface due to the structure of tencel fibre has a smooth uniform surface and a circular cross- section than other regenerated cellulose fibers.

Figure 3.11: Thermal Conductivity

The uniform fabric surface of tencel fabric has high emissivity which produce high heat transfer from fabric to fabric which ultimately increases the air gaps in the fabric structure thereby increasing thermal conductivity [3, 4, 9]. Statistical analysis shows significant difference in thermal conductivity of all the samples.

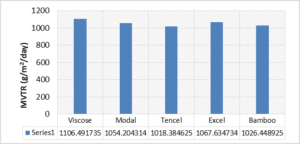

3.2.10 Water Vapor Transmission Rate

Figure 3.12: Water Vapor Transmission Rate

The above fig. 3.12 shows the water vapor permeability is considerably same for all plain woven fabrics. This is because of all fabric samples have approximately same thickness. There are two reasons behind this, first one is all fabrics produced from using same yarn count i.e. 40s. Second one, it is also found that the yarn diameter for all yarns are nearly same. Statistical analysis shows that there is no significant difference in water vapor permeability of all fabric samples.

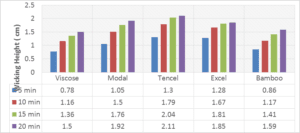

3.2.11 Wicking Height

Wickability of fabrics woven from different yarns is as shown in fig. 3.13. From figure 3.13 it can be seen that the modified viscose fabrics have higher wickability than viscose and bamboo fabrics in both warp and weft way as well as all for all time intervals. However, tencel fabric has maximum wicking behaviour in both warp and weft direction.

Figure 3.15: Wicking Height

Fiber moisture absorption has influence on wicking. Viscose and bamboo fibers has high amorphous area which absorbs more moisture, results in swelling of fibers reduces the gap between the fibers. Also the cellulose crystals of tencel fiber are highly parallel in longitudinal direction of fibre which consists of countless and very hydrophilic crystalline nano-fibrills, which are arranged in a very regular manner and uniformly distributed. These fibrils do not absorb water. The water absorption takes place in the capillaries between the fibrils. The space between these micro fibrils acts like capillaries giving rise to enhanced capillary effect [2, 3]. Statistical analysis shows that wickability of all the fabric samples differ significantly from each other. There is significant effect of time interval on wickability of all the fabric samples.

Conclusions

Tencel fabric is having better characteristics in terms of tensile, thermal, air management, surface and dimensional properties whereas viscose is at lower side. Fibre type has no significant effect on water vapour transmission.

References

- Nazan Erdumlu et al., Investigation of regenerated bamboo fibre and yarn characteristics, Fibres and Textiles in Eastern Europe, vol. 16, 2008, P. 43- 47.

- Parveen Banu et al., Wicking behaviour of viscose staple yarns differing in linear densities, J. Environ. Nanotechnology, Vol.2, 2013, P. 01-05.

- Heinrich Firgo et al., The functional properties of tencel, Lenzinger Berichte, 2006, P. 22 30.

- B. Chavan et al., Development and processing of lyocell, Indian Journal of Fibre & Textile Research, Vol. 29, December 2004, P. 483-492.

- K. Behera., Comfort and handle behaviour of linen-blended fabrics, AUTEX Research Journal, Vol. 7, No. 1, March 2007.

- Tatjana Kreze et al., The sorption behaviour of cellulose fibers, P. 28-33.

- Karin Stana Kleinschek et al., Correlation of regenerated cellulose fibres morphology and surface free energy components, Lenzinger Berichte, Vol. 82, 2003, P. 83-95

- Tugrul Ogulata, Air permeability of woven fabrics, JTATM, Vol. 5, 2006, P. 1-10.

- R. Kaswell, textile fibers, yarns and fabrics, Reinhold publishing corporation, Jan 1953.

- Calvin Woodings, regenerated cellulose fibers, Woodhead publishing limited, 2001.

- Alaa Arafa Badr et al., “Comfort and protection properties of tencel/cotton blends”, Beltwide cotton conferences, New Orleans, LA, January 2014, P. 1009-1020.