Researchers from the Massachusetts Institute of Technology (MIT) and Northeastern University have made a groundbreaking development in the field of smart fabrics.

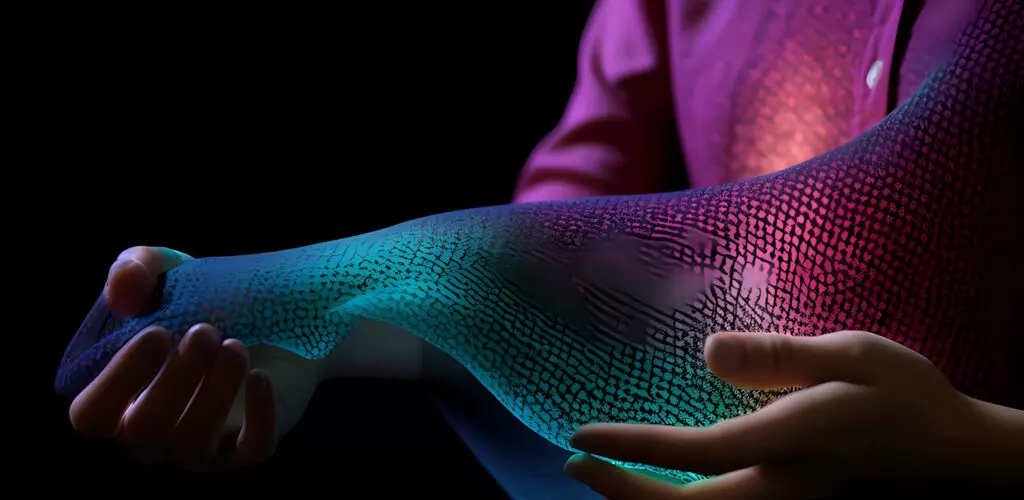

They have created a fibre called FibeRobo, which has the ability to change its shape in response to temperature stimuli. This new fibre could revolutionize the textile industry by enabling the production of high-performance wear, compression garments, and adaptive clothing.

The research, which was presented at the ACM Symposium on User Interface Software and Technology 2023, showcases the potential of liquid crystals in creating production-ready, shape-shifting fibres. The researchers chose a unique type of polymer fibre called liquid crystal elastomer (LCE). This material consists of liquid crystal structures embedded in a stretchy elastomer network.

FibeRobo, the resulting LCE fibre, is highly responsive to changes in heat. When heated, the liquid crystal molecules in the fibre fall out of alignment, causing the elastomer network to contract significantly. As the fibre cools down, the molecules return to their original positions, allowing the material to stretch back out.

Creating FibeRobo requires a carefully controlled chemical synthesis process. By adjusting the chemicals mixed with the LCE fibre, the researchers can control essential properties such as thickness and actuation temperature. They have also developed a preparation technique that ensures the fibre is safe to wear against the skin.

The production process for FibeRobo involves heating a thick LCE resin, extruding it through a thin nozzle, and curing it with UV lights. The resulting fibre is then coated in oil for smoothness and durability. Finally, the fibre is spooled up and coated with powder for easy integration into textile manufacturing machines.

One significant advantage of FibeRobo is its affordability. Producing the fibre with a low-cost setup costs only 20 cents per meter, making it significantly cheaper than other shape-changing fibres in the market.

Furthermore, FibeRobo has the potential to contract up to 40% of its size without bending, providing a wide range of design possibilities.

The researchers have also demonstrated several prototypes using FibeRobo to showcase its potential applications. These prototypes include a compression jacket for pets, which can provide a comforting hug for dogs based on a Bluetooth signal from the owner’s smartphone. They have also created an adaptive sports bra that offers more support during physical activity.

Looking ahead, the researchers aim to further explore the possibilities of FibeRobo by optimizing its chemical composition for recyclability and biodegradability. They also intend to streamline the polymer synthesis process to make it more accessible to non-experts in chemistry.

The invention of FibeRobo opens up an exciting future for smart fabrics. With its practicality, cost-effectiveness, and compatibility with traditional textile manufacturing, FibeRobo has the potential to revolutionize various industries, from fashion and sportswear to healthcare and aerospace.