Abstract

The fashion world is constantly seeking new, natural, eco–friendly textile materials. India, after China, is the second richest country in bamboo genetic resources a novel textile material. The study attempted to utilize bamboo knits in sportswear. 27 designs were sketched (unisex, women and men–9 each) based on a theme Splash and the color forecast Spring Summer 2010.

The bamboo (rayon) fabric was tested for fiber and fabric properties assessing that the sourced fabric was within the minimum expected performance standards. The survey results short–listed the preferred designs by sports persons, retailers and designers. Finally, six designs for unisex, womens and mens designs were produced.

Acceptability and suitability by retailers and sportspersons through another survey was gathered. Use of bamboo knits for sportswear was well accepted showing a high potential for bamboo knitwear in the market. Incorporation of wider colour range and surface embellishments will enhance the appearance of sportswear adding more variety.

Key words

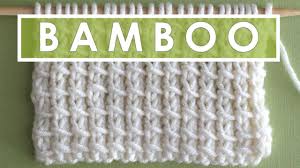

Designing, Product Development, Bamboo, Knits, Sportswear

- Background

Infusion of new creative ideas is the result of technology that is multiplying globally, with diversification of products and processes leading to global competition. This phenomenon is being viewed as a mammoth challenge towards sustainability (capacity to endure tough and diverse conditions). Biodiversity and ‘techno–diversity’ calls for man to explore potentials of available resources. It is imperative to maintain a state of well – being (with regards to health, aesthetics and functionality). There is increased awareness on issues of environmental concerns, organic natural products and eco–friendly processes, effective optimization of resources, etc.

Globally, textile and apparel industry is experiencing paradigm shifts with fashion being the most volatile aspect yet subject to forecasting and cyclic nature. The macro – environment and micro – environment act as determinants and as effects with the dynamism in fashion business (Easey, 2002).

Textile materials have been used in every sport from exercising to camping to football. Sporting activities and liberation of women justified the emergence of knits into the fashionable arena (Adanur, 1995). With changing lifestyles, increased health consciousness and resultant indulgence in leisure and sports activities brought sportswear into limelight in the last few decades affecting clothing purchases in specific and the apparel industry as a whole (Tate, 2004).

Bamboo, as a raw material has a variety of commercial uses, food, construction, decoration, and clothing. Natural anti – bacterial properties, odour resistance, moisture absorptivity, breathability, softness, smoothness, natural UV– protectant/resistance, reduced static electricity build up, ecofriendliness are the unique characteristics of bamboo. Hence these fabrics show promises as a productive textile resource (Xiao, 2009).

Versatility of knit structures characterised by superior strength, softness, water absorbency and textural fluidity of bamboo fabrics have the potential of being used in conjunction, with sportswear technology. Recently, sportswear has an additional sustainable resource of bamboo knits.

1.1 Innovations in Textiles

Significant innovations in textile materials used for sportswear from conventional fibres to high–performance fabrics have occurred. Polyester is predominantly used for sportswear along with other fibres like polyamide, polypropylene, acrylics and elastanes. Wool and cotton fibres find applications in leisurewear (Shishoo, 2005).

The advantage of using manmade fibres is that they can be engineered to suit a variety of end use. Fibre properties and characteristics of fabrics can be attenuated by controlling the process parameters. Fabrics for sportswear are specially constructed considering the geometry, packing density and structure of constituent fibres in yarns and in fabrics which refer to the kinetic mechanisms in fabrics (Shishoo, 2005).

With advancements in chemical, mechanical technology and electronics textile finishing has become indispensable to improve the look, handle, feel and performance (e.g. waterproof, antimicrobial, anti–pilling, UV resistance, thermal insulation, flame proofing) of textiles. Improved fibre spinning techniques, microfibers, nanotechnology, coating and lamination incorporation of phase change materials, bio–mimicry, etc. impart unique performance characteristics with enhanced mechanical, physical, chemical and biological functions required for sportswear. Innovative garment manufacturing technology has resulted in specific designing and product development of novel sophisticated sportswear and footwear for different user categories of performance sports and outdoor leisure activities (Shishoo, 2005).

2.Bamboo fibre

Bamboo is a sustainable resource hence it must be put to substantial use. There are nearly 1500 different species of Bamboo but few are used for textiles. There are two methods of manufacturing bamboo fibres: chemical extraction and mechanical. In chemical processing regeneration of cellulose is essential on similar lines of regenerating conventional viscose rayon. It involves treating cellulose matter with caustic soda yielding alkali cellulose, followed by xanthation with carbon disulphide and then neutralising xanthate with alkali to regenerate cellulose with controlled degree of polymerisation. This is followed by wet–spinning in an acid coagulating bath (Waite 2010).

Figure 1 Flowchart of Manufacturing of regenerated fibres

Source: https://oecotextiles.wordpress.com/2009/08/19/348/

According to US Federal trade Commission (FTC), rayon is a manmade fibre created from cellulose found in plants and processed with harsh chemicals. Bamboo falls in the class of regenerated fibres. Council of Fashion Designers of America agrees that bamboo fibre is less than green. The conversion into filaments and then into yarns and fabrics is similar to that of conventional rayon and is primarily chemical intensive (https://www.treehugger.com)

DyStar Ecology Solutions (2009) dealt with individual fibres describing requirements and restrictions on labelling of bamboo as natural bamboo fabric. Bamboo nevertheless is known for its softness, strong absorbency, anti – microbial properties, comfort, coolness and freshness and is said to be an eco–friendly fibre. Bamboo can be dyed with all dyes recommended for cellulosic fibres. But for the production of a sustainable fibre, the selection of pre–treatments, dyeing and finishing should also be implicitly sustainable and environment friendly.

CTITI (China Textile Industry Testing Institute) and Technical Center of BAMBROTEX constituted standard Bamboo Fibre Identification Rule (BFIR). Cross–section of bamboo fibre is filled with more micro–holes and micro–gaps than common viscose fibre. The notable microstructure renders bamboo unusual breathability and coolness function. This microstructure leads to greater solubility of bamboo in sulphuric acid than common viscose fibre (https://www.swicofil.com/bambrotexbambooidentification.pdf).

Figure 2 Microscopic structures of fibres C.S. and L.S. of bamboo and viscose rayon

(Source: https://www.swicofil.com (bamboo) https://www.policensw.com (viscose)

Zhou et.al registered the process of bamboo yarns (US Patent No. 7313906 B2) in January 2008. The detailed manufacturing parameters and description of bamboo fibre properties is tested and provided.

The chemical composition of bamboo is similar to other bast fibres: constituting majority cellulose and lignin. It has small molecular mass and low degree of polymerization. Cross section of single bamboo fibre is nearly round with small lumen. It is predicted that it has high breaking strength, but low elongation and has good water absorption properties. The structural characteristics of bamboo fibre are different from other plant fibres.

Globally, bamboo textiles are in initial phase and it is conceivable that their market will expand and evolve at a rapid pace. In 2003, Nomura Sangyo in Japan in alliance with Toray and Kurabo patented invention of bamboo fibre manufacturing process. It covers cellulosic fibres derived from bamboo. Bamboo spun yarns with fibre size of 0.5–20 denier made from cellulosic fibres with 400–1,500 twists per meter were used to make woven and knitted fabrics (https://www.greenearthbamboo.com/Eco–Fabric–Trends–Organic–Fashion–s/228.htm)

The earliest patents in bamboo history are for the improvement in preparing fibre from the bamboo US patent nos. 41, 627, 87295 in the years 1864 and 1881 covering the process for disintegrating the fibre of bamboo to be used in manufacturing cordage, cloth, mats, or pulp for paper and mixing wool and bamboo for spinning into yarns. There are a few others dealing with bamboo fibre (https://www.greenearthbamboo.com/Eco–Fabric–Trends–Organic–Fashion–s/228.htm)

Bamboo clothes have strong affinity to dye–stuffs are dye–able in vibrant colours. Its thermal–regulating characteristics to keep the body cool in summer and vice–versa. Bamboo clothes are moisture absorbent having unique wicking ability that prevents clinging under perspiration. Bamboo fibre can be an answer to skin cancer due to its property of natural UV protection (SPF 30+) (hotfrog.com, 2008).

In 2004, Phyllostachys pubescens, Mosobamboo a woody grass was planted in China which grows organically makes a good fabric. Bamboo has anti–bacterial properties and provides around 98 percent UV protection. It is highly breathable in hot weather at the same time provides warmth in the cold. Bamboo is crushed, pulped and then its natural cellulose, which contains the bamboo kun, is extracted to make fibre. It is felt that it is a sustainable addition to the class of natural fibres (Rodman, 2002).

Comparative study of bamboo and cotton knitted fabrics by testing and analysing materials for functional and aesthetic properties showed that bamboo fabrics had moisture regain of almost twice more than cotton, elongation 2 – 3 times more than cotton, resistant towards abrasion and 40 – 50% more than cotton whereas has low bursting strength compared to cotton and a wet strength of only 60% of its dry strength. It indicated that bamboo fabric is more suitable for applications next to skin garments, summer wear, sportswear, home and medical textiles Sheshachala, et al (2008). A study examined the properties of bamboo namely moisture wicking, wear and tear and surface morphology. Bamboo is reported to be a sustainable resource (Waite 2009).

The press release by the US Federal Trade Commission (FTC) charges companies with Bamboo–zling forewarns consumers with false product claims. Companies were charged with deceptive labeling and advertising products as made from bamboo fibre, when they are made of rayon. False and unsubstantiated green eco – friendly, biodegradability claims of products was debated. In March 2009, the Competition Bureau of the Canadian Government issued an announcement regarding accurate labeling of textile articles as derived from bamboo’ (Hardin (2009).

3.Sportswear

Indian sportswear industry currently stands at Rs. 355 billion with CAGR of 45 % for the year 2010–2012, according to the findings of a report titled Sportswear market in India released by RNCOS a market research company. It attributes growth rate to rapid economic growth, huge population base, rising income levels, changing lifestyle and consumer preferences. The study used segmentations of sports footwear and sports apparel, rural/urban divide and gender–wise demand projections. India is an attractive destination for domestic and international sportswear industries (www.sportzpower.com and www.marketpublishers.com).

Expectations of ideal sportswear are comfort properties, good tactile properties, thermal insulation and regulation, breathability, good stretch and dimensional stability, quick liquid absorption, effective moisture management, aesthetic attractiveness, barrier characteristics against external elements, protection from injury. Some of the most famous global brand names, known for their functional designs, performance, quality include Nike, Adidas, Puma, Reebok, Russell Corporation, Umbro, Berghaus, Scanda, Arena, Paramo, Salomon, Rukkla, Sprayway, Helly Hansen and Oscar Jacobsson. There is a strong trend towards combining multi–functional and fashion design for niche markets.

Significant increase in consumption of textile fibres and fabrics for sportswear and sporting related goods was reported in the analysis made by David Rigby Associates in 2002. The report reflects significant rise in population interests worldwide in active indoor and outdoor sports and in leisure pursuits. The social factors that cause this change include increased leisure time, increased considerations of well – being and good health, accessibility of indoor and outdoor sports facilities. Textile materials in various forms are being used in a wide range of applications in sportswear and sporting equipment e.g. aerobic clothing, athletic, football, cricket clothing, games shorts, gloves, jackets, pants, shirts, socks, sweatshirts, swimwear and tennis clothing. Sportswear also covers sporting equipment and footwear.

Consumers need for sportswear is on the rise with leisure, sports, health and fitness management becoming important pursuits. Sports activity and participation have been studied by various research bodies (government and academic). It has been observed that the extent of participation in sports and leisure activities is varied across nations and across different categories of sports. Online sites like the Office of National Statistics UK, Euro stats, NSGA provide useful research data regarding participation of people in different sports activity. The data showed an increase in years 2006-2008 in level of participation in sports and leisure activities(https://www.nsga.org)

There is huge market potential in China. Some supporting facts are giant brand Nike has more than 1,200 stores in China; Adidas was the official partner for 2008 Olympics held in Beijing. There are many sports people with renowned accomplishments from China e.g. Li Ning who won six medals at the Los Angeles Olympic Games in 1984 is also the chairman of a sporting goods firm selling footwear and sportswear with annual sales of US$250 million and more. The company is further expanding by opening more retail outlets (Buirski 2004). China is also foremost in bamboo fibre and fabric manufacture industry. Thus bamboo knits for sportswear is an obvious spotlight area for development in China having potential growth.

Gender plays an important role the development of sports clothing. The strong rise in female participation in sports has been an important factor responsible for development trends in sportswear. It was reported in Textile Outlook International (March/April 2003) that in 2000 ‘US$36.4bn was spent on sport apparel in the USA. Of this as much as US$21.8 billion or around 60% was attributed to purchases by women’.

Menswear takes the shape of sportswear. In fashion history many designs started as sportswear turning into classics of menswear designs e.g. hunting jacket was modelled for a sports jacket, Norfolk jacket created for Edward VII became casual clothing in 1930s, the safari hunting jacket in Africa became craze of fashion by Yves Saint Laurent. Many companies including Burberry, Lilywhites Aquascutum and Jaeger originated as sportswear specialists became major suppliers of menswear to the British middle–class market (Waddell 2005).

4.Designing of sportswear with knits

Sportswear has to be designed and produced using designers skills and knowledge in graphics, textiles and fashion. It involves translating ideas into aesthetically pleasing, ergonomically viable and production feasible products.

Modern sportswear designs incorporate elaborate patchwork and asymmetrical styling. Asymmetrical styling by shifting closures to the sides makes way for patterns with layering. It provides ease of movement and has strong fashion appeal the so–called trendy. Beautiful microfiber bright coloured knits with contrasting trims and off–centre patterns define the styles of recent times. Introduction of high performance and value finished fabrics with specialised finish treatments further expand the pleasures of using functional inner/outer or under/over wear sportswear (first skin and second skin sportswear).

There is noticeable rise in all–in one suit for different categories of sportswear that was originally limited to swimwear and hyped during the 1996 Atlanta Olympics. Nike’s introduced speed skating suits for Salt Lake City Winter Olympics in 2002 Speedo suits. The suits were elaborately constructed with multiple panels. At the same time separates and coordinates in styles are also popular. Novelty in patchwork and layering provides protection and renders enhanced comfort properties with good elasticity compression and warmth protection from sun and aerodynamics. This leads to the development of high – tech suits including the use of high performance knits and fibre innovation (Buirski 2009).

Seamless knitwear extensively used in intimate apparel has tremendous scope for research. Knitwear shows progression in this technology. Seamless knitting since its introduction in 1990 was readily adopted by the industry as it is more expensive than the conventional flat or circular knitting. Apparently, there is also a low market appeal for `seamless shapeless’ undergarments that discourages any R&D efforts in this field (Bramel 2009).

There is a proliferation of global sportswear and casual wear brands. The future for expensive and finely sculpted dresses looks increasingly bleak. Simplicity in design and patterning is the appreciated trend (Jackson and Shaw 2006).

Knitwear was primarily used as practical clothing for warmth, protection and ease of movement. Emancipation of women and their growing interest in sports and rebellious fashion trends brought knitwear into the fashion arena. Coco Chanel took the lead in bringing knitwear of intimate apparel to sportswear and outerwear. Italian knitwear is known for their strengths of quality and craftsmanship (Black 2002).

Knitwear emerged from the realm of sportswear to dominate high fashion. The fashion industry known for its concern in creating style and setting new trends has incorporated ways to be more eco – friendly too. Consumers interest in organic goods has made a take–offKothari and Sanyal (2003).

Knit fabrics are treated with a range of finishes of softening, acid and enzymes washes. Finishing treatments impart desired effects that can change feel and textural appearance of knitted goods (Gokarneshan, et al, 2010).

Designers create identity by performing creative and analytical processes in establishing fashion direction line concept new designs and styles. They are concerned about aesthetics and functionality of their designs. Creative decisions are directed towards balancing fashion components namely colour, texture, silhouette and structural design details in accordance to the principles of design (Burns, 2002).

Product development has overlapping phases of creative design, line adoption and technical design. It involves formulating and implementing design and product specifications which necessitates quality assessment and testing at different stages of designing and developing products (Tarafdar, 2010).

5. The present research study and its purpose

The broad aim of the study was to design and develop sportswear using bamboo (rayon) knits

The specific objectives fulfilled were to:

- Design sportswear (unisex, women and men) incorporating different styles of collars, pockets, fasteners and other details.

- Develop sportswear using most preferred features and patterns for unisex womens and mens garments.

- Ascertain acceptance of bamboo knits as novel raw material source for sportswear.

5.1.Methodology

Sourced bamboo (rayon) fabrics were tested for fibre and fabric properties. Six designs (for unisex, womens and mens) were shortlisted by sports–persons, retailers and designers. Acceptability and suitability by retailers and sportspersons through Survey 2 was gathered.

Figure 3 Colour forecast for Spring Summer 2010 (https://www.docstoc.com/docs/43983867/

FASHIONFORECASTSPRINGSUMMER2010) Logo designing and Theme board Splash

Figure 4 Outline For Methodology

6.2 Results and Discussion

6.2.1 Qualitative Analysis

Visual inspection

Table 1 Visual features of bamboo fabric samples

| Property | Fabric 1 | Fabric 2 |

| Colour | Blue | White |

| Type of knit | Horizontal Single jersey | Horizontal Rib knit |

- Burning test

Fabric samples 1 and 2 showed same behavior towards flame burning tests catching fire easily, producing light coloured ash with burning paper odour. The observations indicated that both fabric samples were composed of cellulosic fibres.

- Microscopic test

The longitudinal view of the fibres showed irregularity with slight striations indicating the given fabric sample contained a regenerated fibre.

- Chemical solubility test

On treatment with dilute acids showed no significant reaction, the fibres however dissolved in concentrated acids. On treatment with alkalis like NaOH fibres swelled and opened up indicating presence of cellulosic fibres.

Conclusions from all three tests (burning, microscopic and solubility)

Fabric 1 and Fabric 2 is composed of a regenerated cellulosic fibre: bamboo (as quoted by the fabric supplier).

6.2.2 Assessment of fabric properties

Table 2 Standard Performance specification for knitted sportswear

| Characteristics | Requirements |

| Bursting strength (load) (ball burst) | 50 lbf (222 N) |

| Colourfastness Shade Change original fabric | Class 4A min |

| Crocking: Wet Dry | Class 4C min Class 3C min |

| Perspiration (acid phase) Shade change Staining | Class 4A min Class 3B min |

| Light (40 AATCC FU) (xenon arc) | Class 4A min |

Source: ASTM D 3782– 02 Standards

Evaluation of fastness tests

- The given bamboo samples had very good wash fastness properties.

- Fabric 1 had good light fastness compared to fabric 2 with fairly good light fastness as white sample showed some yellowing.

- Excellent rubbing fastness was noted and very good perspiration fastness.

- Physical properties

Table 3 Evaluation of physical properties

| Tests | Average Results | |

| Fabric 1 | Fabric 2 | |

| Bursting strength kg/ sq.cm (IS 1966– 1975) | 10.2 | 7.5 |

| Abrasion resistance (Martindales abrasion tester) No. of pills Rating on visual inspection | 22 pills 2 | 18 pills 2 |

| Fabric count Wales/ inch Courses/ inch | 40 42 | 26 36 |

| GSM (ISO 3801– 1977) | 202 | 162 |

| Air permeability cc/sec/cm2 (ASTM D737–96) | 121.52 | 295.12 |

| Wetting (AATCC Test Method 22–2001) | 0 | 0 |

| Elongation % (KES–FB1) | 11 | 15 |

- Bursting strength

The procured bamboo knit has bursting strength of 10.2 g/cm2 (100.02 N/cm2) that is below standard performance specification given in ASTM D3782–02 which is 222 N/cm2. This indicates direction for further research to increasing fabric bursting strength wherein blends of bamboo can be explored.

- Abrasion resistance

Tested samples showed good abrasion resistance with only slight pilling. Sports garments are prone to abrasive forces at the collar and sleeve regions on the underside, inner leg and waistbands. Therefore good abrasion resistance property makes the given bamboo knit samples suitable for sportswear.

- GSM

The weight of single jersey bamboo knit was higher than bamboo rib.

- Fabric count

It is evident from the results that the count of single jersey bamboo knit is higher than bamboo rib. Higher fabric count (i.e. Fabric 1: 40 x 42 and Fabric 2: 26 x 36) showed lower air permeability with higher bursting strength and vice– versa.

- Air permeability

As shown in the table air permeability of single jersey knit is lesser than rib knit. Conclusions on air permeability must be drawn from a comprehensive testing programme as this physical property for a fabric is dependent on the fibre, yarn, fabric and finish performances. Complete testing of fibre, yarn and fabric was not undertaken in the study.

- Water resistance

As per the ASTM D3782–02 performance specification requirement, the wettability of the fabric is excellent. This can be correlated to comfort properties and its good wettability will enhance the easy washability of the fabric.

- Elongation

The fabric showed 11% elongation which is considerably high. Good elongation is one of the necessary requirements for sportswear.

- On qualitative interpretation of three garments (unisex, womens and mens garment 1 each) which were given to 10 sportspersons the respondents that the garments were more comfortable to wear and did not soil heavily in comparison to the garments that the respondents regularly wore during their sports activities. This further supports the suitability of bamboo knits for sportswear.

6.2.3 Survey 1

Objective: To gather preferences for knits as sportswear, preferences for colours, for sportswear, awareness of bamboo fabrics, suitability of bamboo fabrics, preference for purchase of readymade sportswear and preference order in terms of ranking for unisex womens and mens designs for sportswear on the basis of pattern and styling.

- 96% of respondents preferred knits for sportswear and 2% of respondents preferred knits on an occasional basis

- 21% of respondents preferred shade of blue for sportswear and only 2% of the respondents preferred yellow shade.

42% of total respondents (50) were aware of bamboo knits however 58% of the respondents were not aware. 30% of the total respondents (designers) were aware of bamboo fabrics whereas only 4% of the respondents (sports persons) and 8% of respondents (retailers) were aware of bamboo fabric.

Figure 15 Awareness of bamboo fabrics

- 96% of total respondents preferred bamboo knits for sportswear and only 2% of the respondents did not prefer bamboo knits for sportswear.

- 50% of the respondents preferred L followed by 40% preference for M.

- Among unisex designs Style 3 was most preferred followed by Style 5, 6 and 4 ranking second, third and fourth respectively. The least preferred were Styles 1 and 2 ranking fifth and sixth respectively.

Figure 16 Preference order for unisex designs for sportswear

Among womens designs Style 6 was most preferred ranking first followed by Styles 1, 2 5 and 3 ranking second, third, fourth and fifth. The least preferred was Style 4 sixth.

Figure 17 Preference order for womens designs for sportswear

Among mens designs Style 3 ranking first was most preferred followed by Style 5, 6 and 2 ranking second third and fourth. The least preferred were Styles 4 and 1 ranking fifth and sixth respectively.

Figure 18 Preference order for mens designs for sportswear

6.2.4 Survey 2

Objectives of Survey 2

To assess acceptability of bamboo knits for sportswear and to gather preferences for the developed garments with regards to style features, commercial value, preferential pricing of products.

- All styles and garments in general were rated ranging from excellent to satisfactory

- 64% chose the criteria of over–all appearance as compared to the other factors for the selection of the sportswear products.

Figure 19 Factors that affect the choice of the garments during rating

- The data obtained showed that most of the designed garments were suitable for age group of 20 – 29 years or below 19 years of age.

- 84% respondents preferred using of bamboo knits for sportswear products and only 16% did not prefer it.

Figure 20 Preference for use of bamboo knits for sportswear

86% of the respondents preferred buying sportswear products and only 14% did not prefer buying sportswear products.

Figure 21 Preference for purchase of sportswear

48% of the respondents felt that it has scope in the domestic market and 38% felt that it would be commercially accepted in the international market.

Figure 22 Likelihood of commercial acceptability of the produced sportswear

- 44% respondents were of the opinion that the suitable price range for the products is Rs. 1000 1200.

6.3 Summary and Conclusions

The following conclusions were drawn from the research data:

- The preferred shade was blue as it gives feeling of coolness.

- Designers were aware of bamboo knits in contrast to retailers and sportspersons who showed little awareness.

- Equal number of designers, sportspersons and retailers were of the opinion that bamboo fabrics are suitable for sportswear.

- Considering the styling details

– Two – piece garments for sportswear were preferred more than 1–piece suits or jumper types.

– Attached hoods and stand collars were less preferred in comparison to the more preferred styles with sports collar or no collar.

– Sleeveless and half sleeves garments were preferred more in comparison to full sleeve garments.

- The garments were shown to have acceptability on a commercial basis as per the respondents opinions.

- The suitable price range for products is INR. 1000 1200 and the actual cost for one set was approx. INR. 800 1100.

- The given bamboo knit showed good wash, light, rubbing and perspiration fastness.

- Procured bamboo knit samples showed low bursting strength indicating directions for further research aiming to increase bursting strength wherein blends of bamboo or finishes may be explored.

- Sports garments are prone to abrasive forces at the collar sleeve regions on the underside inner leg and waistbands. Therefore good abrasion resistance property makes the given bamboo knit sample suitable for sportswear.

- With higher fabric count, single jersey bamboo knit indicated lower air permeability with higher bursting strength and vice–versa.

- Wettability of the fabric was excellent that is correlated to comfort and easy care properties of fabrics.

- Bamboo knits showed good elongation which is one of the necessary requirements for sportswear.

6.4 Recommendations for further areas of research

- Creating a line of sportswear apparel

- Incorporation of other surface embellishments like printing

- Including a wider colour range

- Dyed fabrics or UV–finished fabrics may be explored instead of white fabrics as it showed yellowing

- UV properties of processed bamboo fabrics may be investigated

- Soiling tests and launderability of fabric/ garments may be conducted

- Bamboo knits can be elaborately tested for physical properties

- Blends of bamboo to be explored to increase bursting strength and dimensional stability of fabric when used for sportswear

7. Bamboo knits – a potential sustainable resource for sportswear

Bamboo knit fabrics have tremendous scope for being used for sportswear designing and product development with positive features of good strength and water absorbency, elasticity, comfort properties and softness. Sportswear is the need of todays consumers and the use of advanced textile and clothing manufacture can provide impetus to the designing and development of sportswear. In conclusion based on the findings of presented research and relevant literature surveyed, bamboo knits certainly have tremendous potential of being used as a sustainable resource in the development of products with a futuristic approach.

8. References

Adanur S (1995), Wellington Sears Handbook of Industrial Textiles, Lancaster, Technomic Publishing Co. Ltd.

Black S (2002), Knitwear in Fashion, London, Thames and Hudson Ltd.

Bramel S (2009), Key trends in sportswear design, Textiles in Sports, England, Woodhead Publishing Ltd. in association with the Textile Institute.

Buirski D (2009), Market Overview Textiles in Sports, England, Woodhead Publishing Ltd in association with the Textile Institute.

Burns L D and Bryant N O (2002), The Business of Fashion, New York Fairchild Publications INC.

DyStar Ecology Solutions (2009), Sustainable Raw Material for Sustainable Textile Production, Colourage, Vol. LVI, No. 10, October, pp. 96–97.

Easey M (2002), Fashion Marketing, Oxford, Blackwell Science Ltd.

Gokarneshan N, Durairaj C Krishnamurthy C, Shanmugasundaram S, Subasree P and Sarnya E (2010), Chemical finishing and washing of knitwear, Manmade Textiles of India SASMIRA Publications, Vol. LIV, April, 2010, pp. 133 137.

Hardin I R, Wilson S, Dhandapani R, and Dhende V, (2009), An assessment of the validity of claims for bamboo fibres, AATCC Review, October 2009, Vol. 9, No. 10. Also available at https://www.aatcc.org/media/Read/bamboo.pdf

Jackson T and Shaw D (2006), The Fashion Handbook, Routledge, Taylor and Francis Group.

Kothari V K and Sanyal P (2003), Fibres and fabrics for active sportswear, Asian Textile Journal, Abstract from Texicon, Vol. 15, No. 12, JanApril, pg. 33.

McKenzie J (1997), The Best in Sportswear Design, London, T. Batsford Ltd.

Qisheng Z, Shenxue J and Yongyu T (2002), Industrial Utilization of Bamboo, Beijing Report for the International Network for Bamboo and Rattan Colourmax Publishers Ltd.

Report Department of Trade and Industry Cottage Industry Technology Center Formulation of a master plan for the development of bamboo as a renewable and sustainable resource (1997) prepared by the Orient Integrated Development Consultants INC.

Rickards L, et al., (2004), Living in Britain Results from the 2002 General Household

Rodman A (2007), Organics fibres the values you wear, September/October, Vol. 18, No. 4.

Sheshachala D, et al, (2008), Comparative study of bamboo and cotton knitted fabric, Man Made Textiles in India, September, pp. 300303.

Shishoo R (2009), Textiles in Sports, England, Woodhead Publishing Ltd. in association with the Textile Institute.

Tarafdar N (2010), Yarn and fabric design technology for fashion apparels, Manmade Textiles in India, Vol. LIV, May, 2010, 167 – 173.

Tate S L (2004), Inside Fashion Design, India, Pearson Education Singapore Pte. Ltd.

Wadell G (2005), How Fashion Works, First Indian Reprint, Oxford Blackwell Science Ltd.

Waite M (2009), Sustainable Textiles: Role of Bamboo and a comparison of Bamboo Textile Properties, Journal Textile and Apparel Technology and Management, Vol.6, Issue 2 Fall 2009, N.C. State University.

World Wide Web:

Xiao S (2009) https://ezinearticles.com/?How–Bamboo–Fibre–Textile–Makes–You–Have–a–Comfortable –Natural–and–Healthy–Lifestyle&id=2879838 (Accessed on 12 /9/2010).

Zhou et al (2008) https://ip.com/patent/US7313906 (Accessed on 5/10/2010)

onlinemarketpublishers.com/report/consumers_goods/sportswear_market_in_india UK Market Publishers Ltd. Abstract (Accessed on 7/10/2010)

www.statistics.gov.uk/lib2002 (Accessed on 6.09.10)

https://www.aiacaonline.org/admin/pdf/researchd.pdf (Accessed on 10/10/2010)

https://www.ftc.com (Accessed on 25.07.08)

https://www.ftc.com.tw/prod_cotton02e.htm (Accessed on 17.09.09)

https://www.ftcamerica.com (Accessed on 10.08.08)

https://www.hotfrog.com/Companies/Bambo (Accessed on 31.07.08)

https://www.kongfi.com/cp_1.htm (Accessed on 7.08.08)

https://www.socksheaven.com (Accessed on 13.08.08)

https://www.swicofil.com/bambrotexbambooidentification.pdf (Accessed on 14.09.10)

https://www.teonline.com/knowledge–centre/bamboo–fiber.html. (Accessed on 6.09.10)

https://www.treehugger.com/files/2009/08/bamboo–ftc.php (Accessed on 20.02.10)

9. Acknowledgement

The authors wish to extending gratitude to the survey respondents, Ms. Asawari (Texan Lab) and Dr. Nachne (CIRCOT Lab) for helping us conduct the tests, Mr. Suresh Kumar (Nidhi Exports) for procuring fabric and facilitating garment production and authorties at College of Home Science, Nirmala Niketan and libraries at various institutes, Mr. Amit Amembal for the help in preparing the presentation and friends.This Full paper is published in the Conference Proceedings TIWC Manchester.

Article By:

DR. VISHAKA ASHISH KARNAD (M.Sc. Ph.D. CTEXT FTI)

ASSOCIATE PROFESSOR, TEXTILE AND FASHION TECHNOLOGY

COLLEGE OF HOME SCIENCE, NIRMALA NIKETAN

(AFFILIATED TO UNIVERSITY OF MUMBAI, NAAC ACCREDITED “A” GRADE)