Approximately 60% of people globally do not have access to clean water, with climate change exacerbating the issue. The textile industry, a major water consumer, is struggling due to water scarcity and environmental changes.

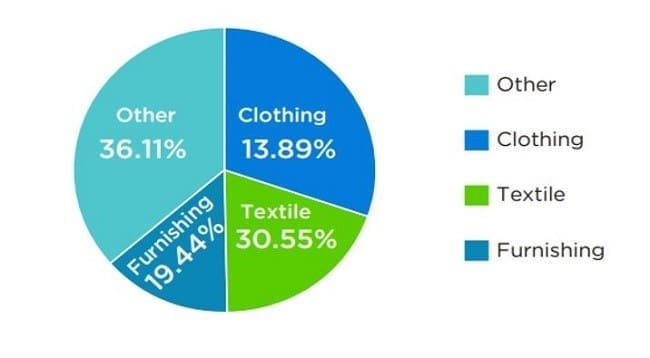

The demand for eco-friendly textile products is increasing in developed countries, leading brands and retailers to focus on clean and transparent supply chains. Governments are also enforcing strict environmental laws. However, traditional textile production methods remain water-intensive and energy-consuming, with 20% or more of water used during dyeing. Manufacturers are turning to new technologies to reduce water usage and energy consumption, contributing to greener solutions in the industry.

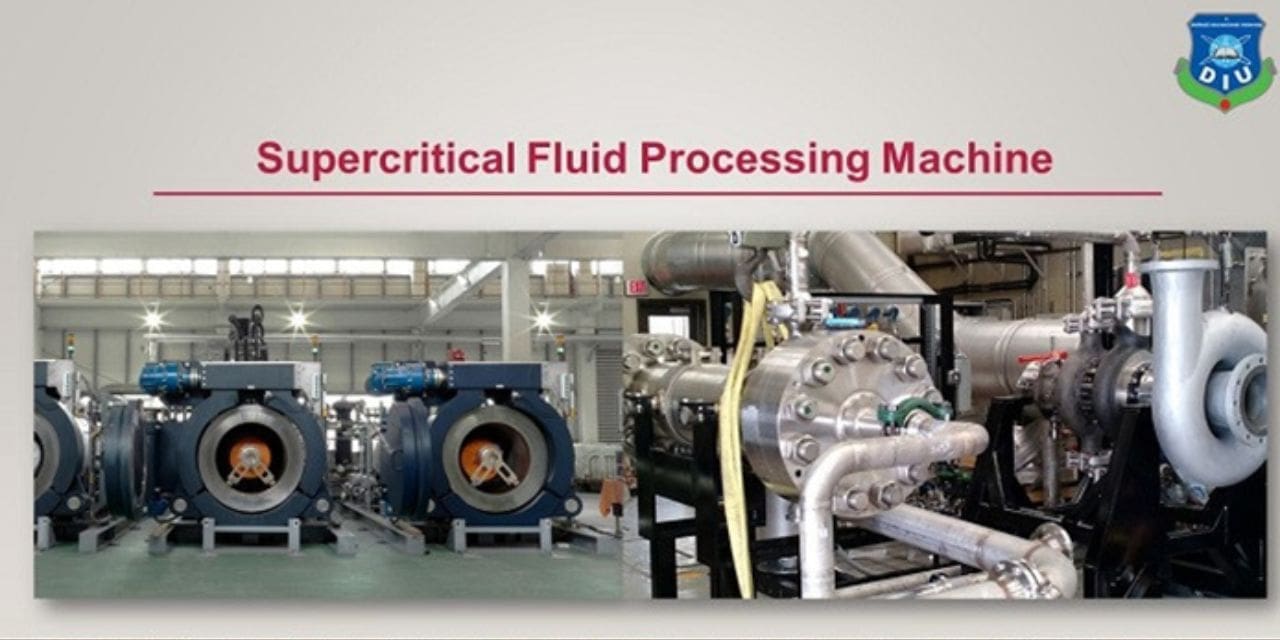

Supercritical fluid dyeing (SFD) technology is a sustainable process that uses supercritical fluids to dye materials. These fluids are maintained at a temperature and pressure above their critical points, allowing them to penetrate and dissolve materials effectively. SFD is a waterless dyeing process that offers unique benefits in the textile industry.

The use of supercritical fluid dyeing (SFD) with carbon dioxide as a solvent has many advantages over traditional water-based dyeing processes. Carbon dioxide is cheap, non-flammable, nontoxic, and has a lower critical point compared to other fluids, making it an attractive option for industrial applications.

SFD technology has evolved significantly since its introduction in the late 1980s. Initially limited to small-scale production and synthetic fibers like polyester, recent advancements have made SFD suitable for large-scale industrial use and various types of fibers, including natural ones like cotton, wool, and silk.

Companies like Dyecoo and Deven Supercriticals have developed equipment and technologies specifically designed for CO2 textile dyeing. Dyecoo’s equipment can handle a wide range of synthetic fabrics and yarns, while Deven Supercriticals’ SUPRAUNO® technology allows for the dyeing of various textiles, including polyester, nylon, cotton, and silk, without the need for water.

Modern SFD technology offers several advantages, including the elimination of reduction clearing and salt usage, improved dye utilization, single-bath dyeing of textile blends, and reduced reliance on auxiliary chemicals. These innovations not only make the dyeing process more environmentally friendly but also provide economic benefits for larger industrial plants.

Modern SFD technology offers several advantages, including the elimination of reduction clearing and salt usage, improved dye utilization, single-bath dyeing of textile blends, and reduced reliance on auxiliary chemicals. These innovations not only make the dyeing process more environmentally friendly but also provide economic benefits for larger industrial plants.

Sustainable Fibre Dyeing uses supercritical CO2 to solvate dye, eliminating the need for water in the dyeing process and saving millions of gallons of water typically used in conventional dyeing methods.

The textile industry generates a significant amount of wastewater through dyeing and finishing processes. Sustainable Fashion Design (SFD) offers a solution by eliminating the need for water, reducing the environmental impact of chemical-laden dye effluents. This innovation could lead to a waste water-free future.

Using supercritical CO2 in the dyeing process reduces the need for additional chemicals, resulting in lower chemical usage and less harmful waste generated compared to traditional dyeing methods.

The SFD method utilizes supercritical CO2 to remove dye from fabric, leaving no solvent residues behind. This innovative process allows for the reuse of dye particles in subsequent dyeing cycles, reducing the amount of textile dyes being dumped annually. The CO2 used can also be recycled and reused, creating a closed-loop system that is environmentally friendly. This addresses the challenges faced by the global textile industry in traditional dyeing methods.

The SFD method utilizes supercritical CO2 to remove dye from fabric, leaving no solvent residues behind. This innovative process allows for the reuse of dye particles in subsequent dyeing cycles, reducing the amount of textile dyes being dumped annually. The CO2 used can also be recycled and reused, creating a closed-loop system that is environmentally friendly. This addresses the challenges faced by the global textile industry in traditional dyeing methods.

The SFD method saves energy by not heating the dye bath, allowing for dry fabric extraction after depressurization. This eliminates rinsing and drying steps, making it a more efficient and eco-friendly dyeing process.

Supercritical fluid’s properties lead to quicker dyeing times, boosting production efficiency compared to traditional methods.

Supercritical CO2 is an excellent dyeing fluid due to its low viscosity and high diffusion properties, allowing for deep penetration of fibers without the need for vigorous convection. This results in vibrant colors and a more sustainable dyeing process, making it a promising alternative for efficient dyeing.

The progress in SFD technology has revolutionized sustainable and efficient dyeing in various textile sectors, although challenges remain in dyeing complex fibers. SFD technology is versatile and scalable, offering a promising solution to the growing demand for eco-friendly textile production. Despite initial high costs and equipment complexity, Bangladeshi textile manufacturers are hesitant to adopt SFD technology due to sourcing challenges. However, the environmental benefits and cost savings of SFD technology outweigh the hurdles, making it appealing in the textile industry.