- Traditional garment dying is one of the most polluting practices in the textile industry and with high production costs.

- Colorbox guarantees high color reproducibility, minimum environmental impact and maximum profitability through an automized and simplified process.

- Allowing a 60% savings in water and chemicals, as well as 45% in energy.

- In 2021 Jeanologia created a saving of more than 18.2 million cubic meters of water, enough to provide the annual human consumption of one million people

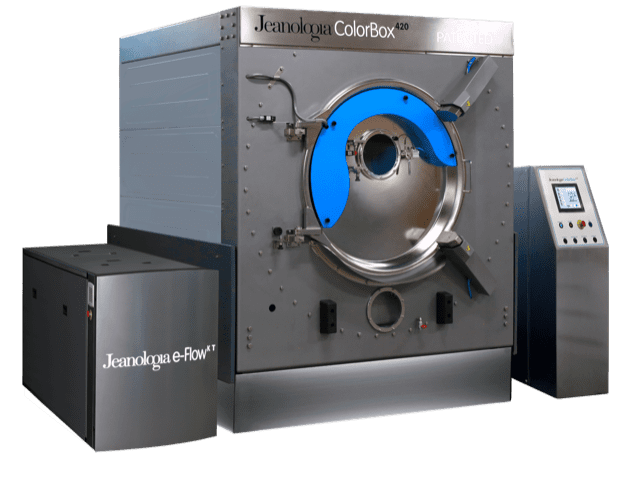

Valencia (14-03-2022).-Jeanologia, world leaders in sustainable and ecoefficient technology development, introduces Colorbox, a revolutionary technology for garment dying transforming the traditional way that garments are dyed in an efficient and faster process that respects the environment.

The dying is one of the most polluting processes in the fashion industry and with high production costs. Jeanologia is committed to creating an ethical and ecoefficient textile industry. This new technology makes an efficient and sustainable alternative possible, hitting a new milestone in the textile industry.

Colorboxreduces the environmental impact of the garment dying process, reducing resource use and pollution load of wastewater.

Through the perfect combination of Jeanologia technologies, the company provides the industry with advanced technical solutions, guaranteeing better production results at a lower environmental and production cost.

Enrique Silla, CEO at Jeanologia, states that Colorbox considerably reduces water, chemical, energy and salts use in comparison with traditional garment dying processes, allowing a low EIM score. “The average saving for water and chemicals is 60%, 45% for energy and 76% for salt in garment dying”.

First time color reproducibility

The main cost of garment dying is the cost of reproducibility. With Colorbox it is possible achieve perfect reproducibility the first time with high-quality products and reduced production times. Jeanologiacreates a new ecoefficientoperating model for garment dying. This technology makes it is possible to dye the product, not only at the beginning of the process, butat any point during the manufacturing of the product, responding quickly to customer demands.

Silla describes how “this allows us to reduce product color decision making deadlines, decreasing lead time to between two weeks and 48 hours in compared with the 18 weeks needed in traditional processes” Silla highlights.

More than 18.2 million cubic meters of water were saved in 2021

For World Water Day next March 22, Jeanologia has published the results of its annual ecological saving count by which it measures the amount of polluted water that is no longer poured into rivers and seas thanks to its technology.

In 2021, Jeanologia increased the amount of water saved and it is now 18,215,000 m3; enough to provide the annual water consumption for one million people.

Also, for the first time, Jeanologia has measured carbon emissions mitigated using its technology. In 2021 the planet has been saved from 83,800,000 kg of CO2 emissions. This is the amount captured by a 100,000 -acre woodland and a similar quantity to what would be eliminated by 5 million trees.

The company continues to work towards its MissionZero: the elimination of 100% of discharge generated in the manufacturing and finishing of Blue Jeans, from the fabric to the final garment, reducing the use of water to near zero and returning clean water to nature.