By Dr.N.N. Mahapatra

Countless Chinese factories producing synthetic dyes for textiles have been closed for environmental inspections since last summer. This led to the emergence of new textile dyeing methods aimed at conserving water, reducing pollution, saving energy, and safeguarding human health. Efforts are underway to revamp processes in the textile industry to minimise the discharge of harmful dyes and chemicals like chromium, arsenic, copper, and zinc.

Research and development (R&D) now emphasises sustainable solutions that comply with legal, voluntary, and brand restrictions on hazardous substances. The primary hurdle lies in costs, as the industry faces intense price competition and shrinking profits due to fluctuating raw material prices and increasing labour costs.

Despite pledges from apparel brands to adopt sustainable practices, suppliers report reluctance from customers to accept even marginal price increases. In this challenging market environment, the focus is shifting towards innovative approaches, as outlined below:

New Dyes

Shree Pushkar Chemicals and Fertilisers Ltd based in Mumbai have unveiled the Dyecol ESR series of reactive dyes, a range of polyreactive dyes designed specifically for cotton. These dyes have a unique ability to bond seamlessly with cotton fibres, setting them apart from conventional reactive dyes. The innovative tri-functional chemical reactivity of Dyecol ESR dyes ensures a rapid and efficient bonding process with the cellulosic fibre, resulting in minimal residual dye that needs to be removed.

Shree Pushkar Chemicals and Fertilisers Ltd based in Mumbai have unveiled the Dyecol ESR series of reactive dyes, a range of polyreactive dyes designed specifically for cotton. These dyes have a unique ability to bond seamlessly with cotton fibres, setting them apart from conventional reactive dyes. The innovative tri-functional chemical reactivity of Dyecol ESR dyes ensures a rapid and efficient bonding process with the cellulosic fibre, resulting in minimal residual dye that needs to be removed.

This groundbreaking technology not only decreases water and energy consumption by up to 50% but also reduces salt usage by as much as 20%. The company aims to revolutionise the dyeing industry with environment-friendly and highly efficient dyes that offer superior performance while conserving resources. Additionally, Shree Pushkar Chemicals and Fertilisers Ltd has introduced salt-free Reactive Dyes under the DYECOL SS series and DYECOL DR series, representing a significant advancement in dye manufacturing, offering pure and high-strength dyes that require a minimal application for achieving deep and rich colours.

Their commitment to sustainability is further evidenced by the launch of PCA-free Blacks, providing a cleaner and safer dyeing option with minimal environmental impact. The company’s continuous innovation is evident with its latest offering, the jet-black DYECOL BLACK DR, which has gained global acclaim for its exceptional quality and performance.

Cotton Pre-Treatment

Cotton dyes use more water compared to other textiles. A kilogram of fabric needs about 200 litres of water. Dow introduced ECOFAST Pure, a pre-treatment method for producing cationic cotton. Treated cotton gains a lasting positive charge, improving its attraction to dyes. The technology lowers water and dye usage by 50%.

Cotton dyes use more water compared to other textiles. A kilogram of fabric needs about 200 litres of water. Dow introduced ECOFAST Pure, a pre-treatment method for producing cationic cotton. Treated cotton gains a lasting positive charge, improving its attraction to dyes. The technology lowers water and dye usage by 50%.

ColorZen’s pre-treatment for raw cotton includes a solution with a wetting agent, caustic soda, and ammonium salt. This technique reduces toxic chemicals by 95% and water wastage by 90%. ColorZen’s cotton pre-treatment starts in the field, accelerating dyeing with 90% less water, 75% less energy, and 90% fewer chemicals. It cuts dye use by nearly half compared to processes with salts.

Supercritical CO2 Dyeing

This leads to the development of new dyes that are halogen and heavy metal-free, with novel chemical structures boasting high exhaust and fixation values. These advancements enable the utilisation of the best available technology (BAT) dyeing methods and the creation of textile goods that meet today’s ecological and technical standards. By adopting these eco-friendly innovations, customers can significantly reduce the environmental footprint of their manufacturing processes through savings in chemicals, water, and energy.

This leads to the development of new dyes that are halogen and heavy metal-free, with novel chemical structures boasting high exhaust and fixation values. These advancements enable the utilisation of the best available technology (BAT) dyeing methods and the creation of textile goods that meet today’s ecological and technical standards. By adopting these eco-friendly innovations, customers can significantly reduce the environmental footprint of their manufacturing processes through savings in chemicals, water, and energy.

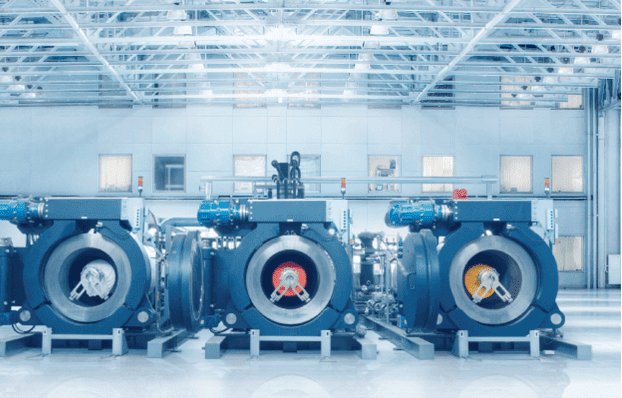

A potential game-changing solution in the industry is the introduction of supercritical CO2 dyeing – a revolutionary process that enables sustainable dyeing without water and eliminates effluents. The increasing importance of water availability and associated costs in textile production countries makes this technology particularly promising. Compared to traditional aqueous dyeing techniques, supercritical CO2 dyeing results in significantly lower water and energy usage, as well as faster dyeing cycles. Notably, this method achieves high dye fixation and uniformity in polyester dyeing without the need for dispersing agents or auxiliary chemicals.

Furthermore, the non-toxic nature of carbon dioxide used in the process, coupled with its high recyclability, sets it apart from solvent-based dyeing methods. Major industry players like Nike and Adidas have already embraced this environmentally friendly approach in select product lines and marketing initiatives. Manufacturers like DyeCoo are actively implementing this technology, particularly in batch and beam dyeing processes, with ongoing research to expand its applicability to various substrates.

Pre-Reducing Indigo

University of California scientists are creating denim dyes by genetically modifying E.coli bacteria to synthesise indican, then converting it into indigo through enzymatic treatment. This innovative technique eliminates the necessity for harsh chemical reducers in indigo dye production by utilising an enzyme instead. However, further refinement is needed to enhance the recovery of indican for long-term viability.

University of California scientists are creating denim dyes by genetically modifying E.coli bacteria to synthesise indican, then converting it into indigo through enzymatic treatment. This innovative technique eliminates the necessity for harsh chemical reducers in indigo dye production by utilising an enzyme instead. However, further refinement is needed to enhance the recovery of indican for long-term viability.

Leveraging enhanced resources, eco-friendly dye materials and an extensive background in the textile industry, web-based tools have been engineered to aid in sustainable process optimization and product selection. Additionally, the use of pre-reduced indigo liquid in denim manufacturing promotes cleaner production practices and significantly reduces sodium hydrosulphite usage, minimises wastewater pollution, and conserves water resources.

Furthermore, real-time monitoring of key dyeing parameters like indigo concentration, pH levels, temperature, and electrolyte concentration online facilitates process optimization and resource conservation. Archroma, a leading colour chemical provider, has devised a method for pre-reducing indigo to prevent the release of harmful chemicals during downstream processes.

Engineered Microbes

Colorifix adopts a bio-based method involving bacteria to dye textiles, cutting water consumption significantly. The technique involves immobilising dye-producing bacteria on fabric with a carbon solution, followed by fixing the dye through a single heat treatment achieved by lysing microbes. Notably, this method eliminates the need for traditional dye extraction using organic solvents or organic compound-based agents for fixation and reduction. Various startups are exploring microbial engineering to minimise chemical use in textile dyeing; an instance is the UK’s Colorfix, experimenting with genetically altered microbes to produce lasting colours.

Colorifix adopts a bio-based method involving bacteria to dye textiles, cutting water consumption significantly. The technique involves immobilising dye-producing bacteria on fabric with a carbon solution, followed by fixing the dye through a single heat treatment achieved by lysing microbes. Notably, this method eliminates the need for traditional dye extraction using organic solvents or organic compound-based agents for fixation and reduction. Various startups are exploring microbial engineering to minimise chemical use in textile dyeing; an instance is the UK’s Colorfix, experimenting with genetically altered microbes to produce lasting colours.

Digital Textile Printing

The significant amount of water used for textile dyeing happens post-dyeing, especially with cotton which requires repeated washing to remove unfixed dye. An alternative to dyeing is using pigments, demonstrated by Intech Digital’s large-scale printers equipped with specialised ink-jet print heads for textiles.

The significant amount of water used for textile dyeing happens post-dyeing, especially with cotton which requires repeated washing to remove unfixed dye. An alternative to dyeing is using pigments, demonstrated by Intech Digital’s large-scale printers equipped with specialised ink-jet print heads for textiles.

Over the past five years, digital printing market growth has been remarkable, driven by innovations in printer and print head technology, creating a need for new inks to cater to upscale industrial digital printing. The evolution of digital textile printing technology marks a crucial advancement towards more sustainable textile printing practices.

New ink formulations are essential, meeting the evolving demands of digital textile printing companies – necessitating superior drop formation, extended open times, enhanced durability, vibrant colours, and eco-friendly and high-fastness properties. Responding to industry standards, DyStar introduced Jettex 4.0, a superior digital textile printing ink. Additionally, ultraintense inks are now available, enhancing print head longevity and operation ease while offering a wide range of vivid colours suitable for creating impactful fashion designs.

These newly developed inks surpass existing standards by meeting strict ecological and fastness criteria. Notably, fulfilling high fastness requirements for home textiles has been a challenge for digital printing systems in the past. DyStar’s innovation, Jettex Vat, represents a breakthrough – the first high-performance industrial Vat inks in the market, leveraging Indanthren Vat dyes for superior performance.

Powder Dyes From Textile Fibres

Officina+39, a company from Italy, created Recycrom, an eco-friendly dye line made from recycled textiles and fabric scraps. They designed an innovative eight-step process (patent pending) to transform fabric fibres into fine powder for dyeing cotton, wool, nylon, and other natural fabrics. Recycrom can be incorporated into fabrics through methods like exhaustion dyeing, dipping, spraying, screen printing, and coating. Unlike traditional dyes that are chemical solutions, Recycrom is used as a suspension, making it simpler to filter from water and decreasing its environmental footprint.

Officina+39, a company from Italy, created Recycrom, an eco-friendly dye line made from recycled textiles and fabric scraps. They designed an innovative eight-step process (patent pending) to transform fabric fibres into fine powder for dyeing cotton, wool, nylon, and other natural fabrics. Recycrom can be incorporated into fabrics through methods like exhaustion dyeing, dipping, spraying, screen printing, and coating. Unlike traditional dyes that are chemical solutions, Recycrom is used as a suspension, making it simpler to filter from water and decreasing its environmental footprint.

Hybrid Pigments

Eco foot innovated with hybrid pigments that bond dye to polymer particles to interact at low temperatures, eliminating the need for salt when dyeing fabrics. This technology revolutionises eco-friendly dyeing for cotton and wool, offering a sustainable alternative. Their Eco foot-Indigo pigment for denim dyeing avoids toxic reducing agents, which can be harmful to the environment. Additionally, Eco foot developed auxiliaries that prevent dye hydrolysis, reducing the need for intensive washing procedures. By combining hybrid pigments and auxiliaries, over 50 per cent of water can be conserved in the dyeing process, benefiting both the environment and the efficiency of production.

In addition to these dyeing techniques, alternative solutions are gaining prominence. Despite the effectiveness of pretreatment methods, the health risks associated with dyes and their chemical components persist. This issue is central to various eco-certification initiatives within the textile industry. The Oeko-Tex certification, which focuses on non-toxic textiles, now assesses over 300 substances compared to the initial 100.

Denim manufacturers, in particular, face growing pressure to revamp their production processes. Recently, Levi’s introduced a pilot initiative named Project Future-Led Execution, aimed at reducing chemicals in finishing procedures and accelerating time-to-market. Likewise, G-Star Raw undertook a comprehensive assessment of its supply chain and introduced what they describe as “the most environmentally friendly jeans to date.