Introduction

In the global Textile industry, India occupies a prominent position. The size of India’s Textile market as of November 2017 was around US$ 150 bn, which is expected to touch US$ 223 bn by 2021, growing at a CAGR of 10.14% between 2009-21E. Enhanced per capita income, favourable demographics, shift in preference to branded products, increased penetration of organised retailers, increasing investment by government under scheme for Integrated Textile Parks, abundant availability of raw materials (cotton, wool, silk, jute) and Policy support are the major factors for boosting demand. Textile industry plays a vital role in the Indian economy through its contribution to the export earnings (15% in 2017-18), employment generation (~21%) and overall Index of Industrial Production (IIP) (~14%). The fundamental strength of the textile industry in India is its strong production base of a wide range of fibre | yarns from natural fibres like cotton, jute, silk, wool to regenerated |man-made fibres like viscose, polyester, nylon, acrylic, etc. Textile is an integral part of human life, a basic necessity for maintaining modesty, providing protection and improving aesthetics.

Importance of Vat dyes

Contribution of wet processing operation is massive in colouration industries and fastness properties are the major quality parameters demanded by the end users. Though reactive dyes are widely used for dyeing of cellulosic substrates, the impact of Vat dyes is enormous due to their highest level of fastness properties and with an understanding that ‘colour lasts till the fibre lasts’.

Vat dyes display following major advantages in terms of fastness properties over other classes of dyes:

- Highest light as well as weathering fastness

- Superior perspiration light fastness

- Stable to repeated laundering in detergents containing bleach activators

- Outstanding chlorine fastness

- Good dry-cleaning fastness

- Superior benzoyl peroxide fastness

- Excellent fastness to oxidative bleach

Designed to meet the highest performance standards, vat dyed goods are widely used in the following important segments:

- Workwear | Uniforms (Military camouflage | Police| Fire-brigade | School)

- Hospital use (Bed sheet, Towels, Surgical clothing)

- Fast to Light and Weather outerwear

- High-end Shirtings | Bottoms | Sportswear

- Household articles (Towels | Bed linen| Curtains | Upholstery fabrics)

- Sewing threads

- Outdoor use (Tents, Awnings, Parasols)

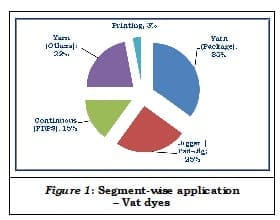

The estimated segment-wise application of vat dyes is presented in

Figure 1:

Continuous dyeing – Importance and overview

Fierce competition due to the globalisation of the textile supply chain has forced the dyers to increase overall production efficiencies by reducing costs of power | water | steam | effluent treatment. The key initiatives to achieve economies of scale include machinery modernisation, technology upgradation, innovative application techniques, cost optimised processing and increasing production capacities. Sustainability concept, eco-regulations, optimisation of cost, stringent quality norms and evolving fashion trends have also forced the dyers to accept a quantum shift in the processing technologies. Only shifting from batch wise application to continuous processing supports the processors to enhance the productivity as well as to achieve reduction in utility | effluent treatment cost. So, the reasons for opting continuous dyeing include

- Enhanced productivity

- Uniformity of shades in long yardages

- Better process control

- Better reproducibility

- Production flexibility

- Low utility cost

Table 1 shows the qualitative comparison of continuous dyeing against conventional exhaust dyeing operation:

| Table 1: Qualitative comparison –

Continuous vs Exhaust dyeing |

|||

| No | Feature | Exhaust | Continuous |

| 1 | Productivity | + | + + + |

| 2 | Reproducibility | + + | + + + |

| 3 | Dyeing cycle time | + | + + + |

| 4 | Longer run of fabric | + | + + + |

| 5 | Uniformity of dyeing | + + | + + |

| 6 | Penetration of colour | + + | + + + |

| 7 | Cost of steam | + | + + |

| 8 | Cost of water | + | + + |

| 9 | Cost of labour | + | + + + |

| 10 | Spot correction during dyeing | + + | + |

| 11 | Cost of machine | + + | + |

| 12 | Re-dyeing | + + | + |

| + | Advantageous |

| + + | More Advantageous |

| + + + | Most Advantageous |

Continuous dyeing with Vat dyes

For Continuous dyeing with Vat dyes, Pad – Dry – Chemical Pad – Steam (PDPS) process is widely used around the globe. The schematic diagram is presented in Figure 2:

Though advantageous and highly recommended process, some common problems in PDPS dyeing are occasionally encountered by the dyer, viz colour specks | patches, non-solid appearance, poor penetration of dyestuffs, center-selvedge variation, face-back variation, tailing, laboratory-to-bulk and bulk-to-bulk reproducibility, inadequate fastness properties, crease marks, etc. In this context, the significance of the quality parameters of Vat dyes is enormous. Atul Ltd, a member of prestigious Lalbhai group, is pioneer in manufacturing of NOVATIC range of Vat dyes. With the state-of-art manufacturing infrastructure, dedicated R&D, stringent quality standardisation norms and environment protection facilities, Atul Ltd has secured significant position globally. Atul Ltd offers NOVATIC MD range of Vat dyes, which play a major role to achieve trouble-free dyeing | RFT performance in continuous dyeing operation.

NOVATIC MD range – superior Vat dyes for continuous dyeing

The innovative NOVATIC MD Vat dyes are specially designed for application by continuous dyeing method on cellulosic substrates and their blends, to satisfy customer’s desired rigorous requirements for meeting the most demanding specifications of retailer | brands. These dyes are suitable for a wide shade spectrum and satisfy stringent | critical fastness requirements as per various international standards.

The salient features and associated benefits are summarized in Table 2:

| Table 2: Features and Benefits – NOVATIC MD Vat dyes | |

| Features | Benefits |

| Non dusting powder | Ready to use formulation |

| Super fine, micro-molecular particle size | Speck free performance |

| Non-foaming and non-mal odorous | Ease of reduction and handling |

| Uniform build-up | Ease of shade matching |

| High dye migration | Reproducibility and uniform level dyeing |

| Minimal staining on Polyester | Colour solidity in Polyester| Cellulose blends |

| Optimal thermal stability | Minimal shade change during finishing |

| Stringent quality norms | Consistency and reproducibility in dyeing |

| High fastness parameters | Meets critical end use requirements |

For ensuring quality parameters of the prestigious NOVATIC MD range, each and every manufactured blend is passed through several specified stringent quality control check points and standardisation norms.

The salient features of NOVATIC MD dyestuffs are furnished below:

Selection of dyestuffs in combination plays a vital role to determine the performance properties of recipes. A guideline chart is presented in Table 3:

Summary

Continuous dyeing helps to minimise the impact of water, energy, effluent treatment costs; poor reproducibility and enhances per person productivity. Controlled continuous dyeing with Vat dyes is considered to be an effective method for producing large volumes of consistently dyed quality fabric satisfying stringent and critical fastness properties. NOVATIC MD range of speciality Vat dyes offers a tailor-made solution to satisfy stringent performance as well as colour fastness expectations of the end users.

References

- India Brand Equity Foundation (IBEF); www.ibef.org; March 2019

- Athalye A, Chakraborty A and Shirke V; Colourage; September 2008; p. 82

V R Sai Ganesh, Arindam Chakraborty and Jignesh Bilimoria

Atul Ltd (Colors Business), Atul, Dist. Valsad, Gujarat