Rapid evaporation is a crucial characteristic of fabrics that are worn in close contact with the skin, particularly during physical activities that induce sweating. In the absence of this attribute, sweat does not readily evaporate from the fabric, resulting in discomfort for the person wearing it.

Drying rate

The drying rate of a textile refers to its ability to expel moisture and revert to a dry condition at a rapid pace. When selecting materials for different purposes, such sporting wear or outdoor gear, it is crucial to take this issue into account.

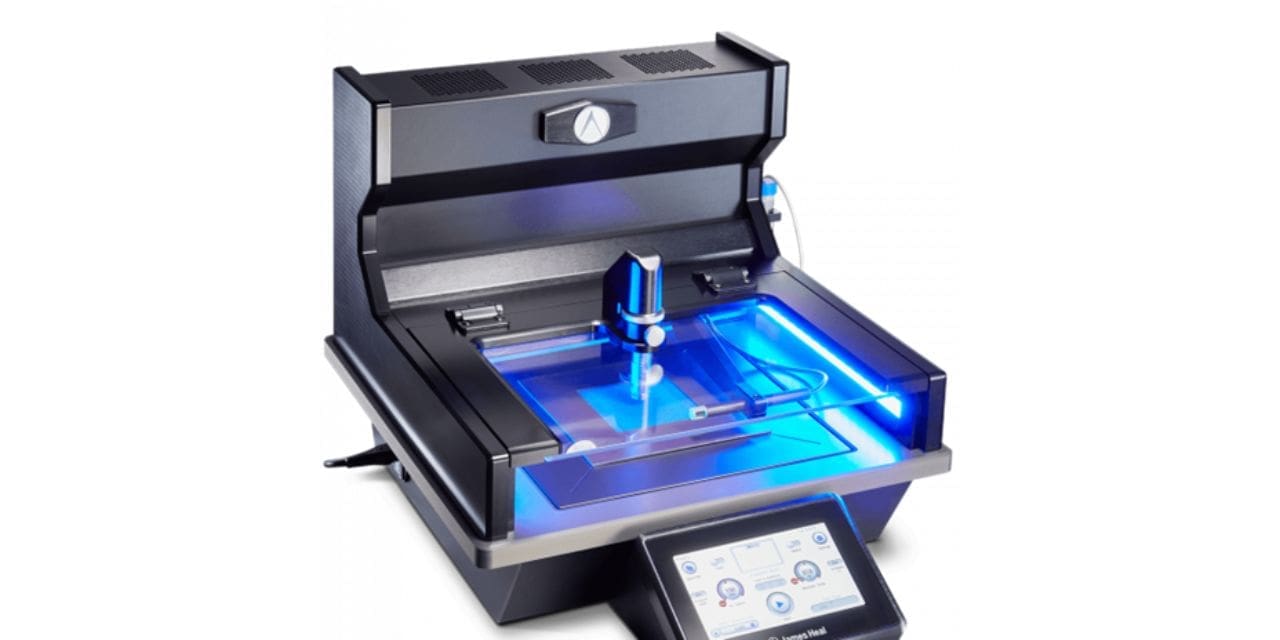

Drying rate tester

Drying rate testers simulates the usage conditions to ensure that fast-drying materials are functioning efficiently. This technique is employed in the production of fast-drying textiles and clothing items, including base layer garments, football kits, running gear, gym gear, socks, and footwear. It is also crucial in the manufacturing of high-performance materials used in uniforms for military and emergency services personnel.

In this article we are going to discuss about drying rate tester that follows AATCC TM 201: Drying Rate of Fabrics: Heated Plate method.

In order to quickly imitate the process of human sweating and fast calculate the drying rate of textiles, drying rate tester is equipped with

- High-precision temperature sensors, wind speed sensors, precision water dripping devices, and other similar devices.

- The uniquely built parallel cross-flow fan improves wind speed uniformity and smoothness,

- The sample is dried by an internal anemometer in the device.

- The sample’s temperature change is detected by an infrared temperature sensor to ascertain when drying is complete.

Principle

This test technique measures the pace at which a fabric dries after being submerged in a specified amount of water and coming into contact with a heated plate that is set at 37 °C—the temperature at which human skin begins to perspire. All fabric types, including knit, woven, and non-woven, as well as fabrics extracted from finished products, can be processed using this technique.

Working procedure

- The sample’s initial mass is measured and recorded

- A particular amount of water rises from the drying rate tester’s bottom to the middle of the plate, mimicking sweating, saturating the test sample, which is set on top of the heating plate at a constant 37° (99°F).

- Test conditions are guaranteed by a closed-loop control system (heated metal plate and air flow).

- The ideal humidity, airflow, and temperature are established.

- When the specimen is wet, the temperature decreases, and as it dries, the temperature progressively rises.

- This temperature difference is recorded by the software, which then automatically determines the tested specimen’s drying time and rate.

Factors affecting the evaporation rate

Factors affecting the evaporation rate

- Temperature: Since higher temperatures give liquid molecules more energy to escape into the air, evaporation occur more quickly.

- Humidity: Since drier air can absorb more moisture, lower humidity levels speed up evaporation.

- Airflow: By forcing drier air to replace saturated air on the liquid surface, more airflow across it promotes evaporation.

- Surface Area: More molecules can evaporate at once on a bigger surface area, which accelerates the process overall.

Future of drying rate tester

To ensure quality drying rate calculation smart drying rate tester has been introduced. This instrument follows the AATCC test method TM201 and allows for remote parameter setting and test process monitoring, both of which significantly increase operational efficiency.

- Through the use of a smartphone app, smart drying rate tester can be networked, and test results can be shared with others and include the drying rate curve, drying time, and equipment warning alerts.

- Test result is more reliable, convenient, and efficient.

- The drying rate test can be finished in ten minutes or less as there is a precision drip device, wind speed sensor, and high-precision temperature sensor in the instrument.

- Smart dry rate tester’s uniquely shaped parallel crossflow fan increases wind speed uniformity and smoothness, displays the real evaporation process and improving the accuracy of the cloth drying test findings.

- Using this instrument is straightforward and simple. The entire fabric drying test procedure can be shown as a readable data curve on the screen.

Thus, by accurately measuring the evaporation rate of liquids under controlled conditions, this device ensures that product to be tested perform as expected in their intended applications.

References

- https://www.gester-instruments.com/aatcc-201-drying-rate-tester-gt-d61_p664.html

- https://www.jamesheal.com/prodry-dry-rate-tester-feature#:~:text=About%20the%20test%20method,human%20skin%20begins%20to%20perspire.

- https://members.aatcc.org/store/tm201/955/

- https://www.testextextile.com/product/smartdry-drying-rate-tester/