As the birthplace of spinning, weaving and knitting – and virtually all other related supply chain processes – a vast knowledge bank on how best to effectively run modern and vertically-integrated textile manufacturing plants

has been built up in the UK.

This is reflected in the leading position that has been established by members of the British Textile Machinery Association (BTMA) in the areas of testing, instrumentation and machine control that will be highlighted at the forthcoming ITMA 2023 in Milan.

“An extensive range of technologies and services from the UK will be on display in Milan, with over 30 of our members in attendance,” says BTMA CEO Jason Kent.

“Some of their most recent developments are really going beyond what has previously been possible.”

Reading the patterns These include the ground breaking new fabric inspection technique for accurately detecting the most subtle of defects on patterned fabrics during high speed production developed by Shelton Vision (Hall 18, stand A304a).

This patent-pending system has been integrated into the company’s WebSpector platform and is already fully validated, with the first industrial installations now in place.

Traditional methods for defect detection rely on human inspection with detection rates under 65%, while the Shelton WebSpector machine vision system offers automated defect detection of over 97%, but until now has been restricted to plain textiles.

“What our new system does is essentially make the ‘good’ pattern invisible to the detection software,” explains Shelton Vision Managing Director and CEO Mark Shelton. “Building on our market leading vision system for plain textiles, we have developed template matching techniques for the resolution of complex pattern deformations in order for the system to pick up defects in the pattern as well as underlying defects.”

SONY DSC

Colour assessment

In another important new introduction, VeriVide (Hall 4, stand B204) will introduce UltraView – its first all-LED light booth for achieving a new level of consistent and standardised colour assessment.

The company’s light booths and lighting cabinets are specified by major global retailers around the world, who rely on them for establishing and maintaining visual quality standards across their supply chains.

UltraView brings a range of sustainable new benefits to designers, mills and brands, and combined with VeriVide’s highly successful DigiEye system for non-contact colour measurement and digital imaging, can have a very positive impact on a company’s bottom line, bringing savings in time, money and CO2 emissions.

IR bonding

Roaches international is another globally recognised manufacturer and supplier of laboratory dyeing and finishing equipment and textile performance testing instruments for major brands.

On its largest ITMA stand to date (Hall 4, stand E302), the company will introduce its IR Bonder – a single end bond applicator and infrared (IR) curing chamber with extremely low electrical consumption.

The IR Bonder is integrated with a single head winder and has a potentially broad range of application markets such as the automotive and medical sectors.

Its drying mechanism simulates current coating technology and standard winding equipment to bond sewing threads by the application of a nylon terpolymer, which is applied in solution form. The solution – comprised of ethanol/methanol and water – is evaporated and the thread cooled before being lubricated and wound onto either an

intermediary or final spool. Available with up to six positions, the system has a running speed of up to 600 metres per minute.

Roaches will also be soft launching its Luft performance haptics tester, developed with Leeds University, to enable a heightened understanding of how specific garments will feel and perform.

Digitalisation

Monarch Knitting Machinery will be unveiling four of its latest circular knitting machines at stand E105-6 in Hall 4, along with new design simulation software and the MMS (Monarch Monitoring System) for Industry 4.0 taking fabric digitalisation to the next level.

MMS, developed with partner BMS (Belgium Monitoring Systems) not only monitors knitting machines but also all manufacturing and logistical activities within the knitting factory.

In addition, Monarch will introduce a new concept for fabric simulation which allows designers to develop fabrics digitally. The software simulates the design in 2.5D and creates the pattern data for the machine using the most appropriate stitch formation, allowing for the creation of fabric collections and or pre-selections prior to production.

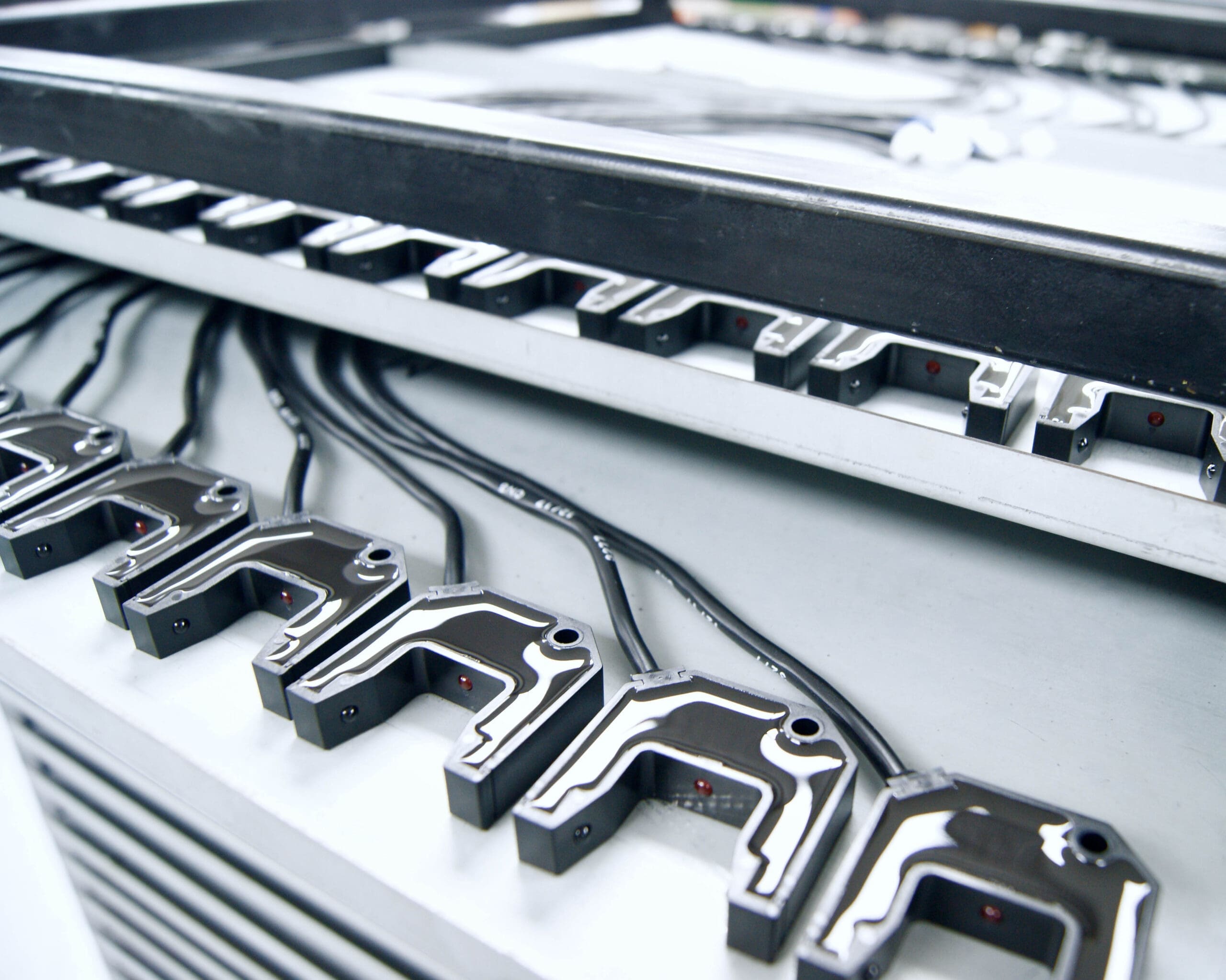

Dent sensors

Sensors from Dent Instrumentation (Hall 3, stand E302) are integral to the yarn spinning and winding processes and they have become the standard throughout the textile industry, recognised for their quality, performance and value. They are used by major manufacturers of textiles and textile machinery under either Dent or OEM

machine builder brands.

The highly accurate sensors are effective at speeds as low as 3m/min up to 8,000m/min, and their detection response can be adapted to each individual unit according to customer requirements.

The ‘fit and forget’ sensors are extremely durable in all operating environments and encapsulated in epoxy resin to provide protection from spin finish, oil, wax, water and any other potential contaminants. A unique optical compensation system also contributes to ensuring very little cleaning is required.

Emphasis

“Sustainability, circularity and Industry 4.0 have been the primary themes coming from the market for some time now and our members have responded with innovations spanning the entire supply chain, and with a specific emphasis in many cases on improved software and digitised control solutions,” says Jason Kent in conclusion.

Founded in 1940, the British Textile Machinery Association actively promotes British textile machinery manufacturers and their products to the world. The non-proforganisation acts as a bridge between its members and the increasingly diverse industries within the textile manufacturing sector.