INTRODUCTION – Carbon fibre is also called as graphite fibre. Carbon fibre was developed in the mid 1960s. It is first found by Dr. Roger Bacon. It is in the form of several long strands of materials mainly composed by carbon atoms. Each strand is 0.005-0.010mm thick in diameter. Its density is much lower than density of steel.

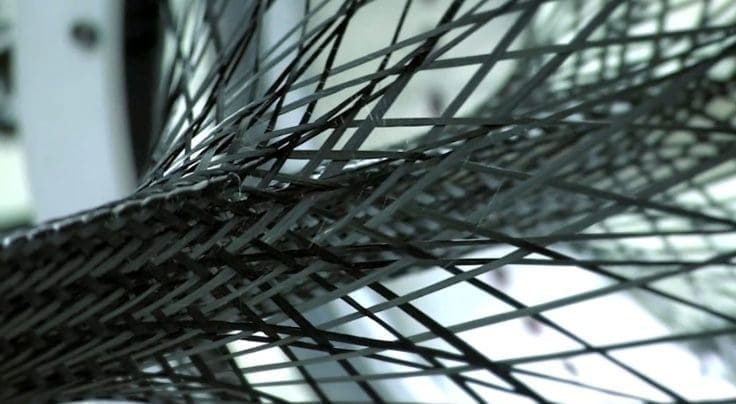

CARBON FIBRES – A material consisting of thin, strong crystalline filaments of carbon, used as a strengthening material, especially in resins and ceramics. It is five times as strong as steel two times as stiff, yet weighs about two-thirds less. Carbon fiber is basically very thin strands of carbon even thinner than human hair. The strands can be twisted together like yarn. The yarns can be woven together like cloth. Carbon fibers are fibers about 5-10 micrometers in diameter and composed mostly of carbon atoms. Carbon fibers are fire resistance / non flammable. Carbon fibers have several advantages such as

High stiffness

High tensile strength

Low weight high chemical resistance

High temperature tolerance

Low thermal expansion.

APPLICATIONS

- Aviation and aerospace

- Robotics

- Medical equipment

- Unmanned aerial vehicles

- Race cars

- Boats and all kinds of sports equipment such as paddles and racquets, and bicycles.

MANUFACTURING PROCESS

The raw material used to make carbon fiber is called the precursor. About 90% of the carbon fibers produced are made from polyacrylonitrile (PAN). The remaining 10% are made from rayon or petroleum pitch. All of these materials are organic polymers, characterized by long strings of molecules bound together by carbon atoms. The exact composition of each precursor varies from one company to another and is generally considered a trade secret.

During the manufacturing process, a variety of gases and liquids are used. Some of these materials are designed to react with the fiber to achieve a specific effect. Other materials are designed not to react or to prevent certain reactions with the fiber. The process for making carbon fibers is part chemical and part mechanical. The precursor is drawn into long strands or fibers and then heated to a very high temperature without allowing it to come in contact with oxygen. Without oxygen, the fiber cannot burn. Instead, the high temperature causes the atoms in the fiber to vibrate violently until most of the non-carbon atoms are expelled. This process is called carbonization and leaves a fiber composed of long, tightly interlocked chains of carbon atoms with only a few non-carbon atoms remaining.

Stabilizing

Before the fibers are carbonized, they need to be chemically altered to convert their linear atomic bonding to a more thermally stable ladder bonding. This is accomplished by heating the fibers in air to about 390-590° F (200-300° C) for 30-120 minutes. This causes the fibers to pick up oxygen molecules from the air and rearrange their atomic bonding pattern. The stabilizing chemical reactions are complex and involve several steps, some of which occur simultaneously. They also generate their own heat, which must be controlled to avoid overheating the fibers. Commercially, the stabilization process uses a variety of equipment and techniques. In some processes, the fibers are drawn through a series of heated chambers. In others, the fibers pass over hot rollers and through beds of loose materials held in suspension by a flow of hot air. Some processes use heated air mixed with certain gases that chemically accelerate the stabilization.

Carbonizing

Once the fibers are stabilized, they are heated to a temperature of about 1,830-5,500° F (1,000-3,000° C) for several minutes in a furnace filled with a gas mixture that does not contain oxygen. The lack of oxygen prevents the fibers from burning in the very high temperatures. The gas pressure inside the furnace is kept higher than the outside air pressure and the points where the fibers enter and exit the furnace are sealed to keep oxygen from entering. As the fibers are heated, they begin to lose their non-carbon atoms, plus a few carbon atoms, in the form of various gases including water vapor, ammonia, carbon monoxide, carbon dioxide, hydrogen, nitrogen, and others. As the non-carbon atoms are expelled, the remaining carbon atoms form tightly bonded carbon crystals that are aligned more or less parallel to the long axis of the fiber. In some processes, two furnaces operating at two different temperatures are used to better control the rate of heating during carbonization.

Treating the surface

After carbonizing, the fibers have a surface that does not bond well with the epoxies and other materials used in composite materials. To give the fibers better bonding properties, their surface is slightly oxidized. The addition of oxygen atoms to the surface provides better chemical bonding properties and also etches and roughens the surface for better mechanical bonding properties. Oxidation can be achieved by immersing the fibers in various gases such as air, carbon dioxide, or ozone; or in various liquids such as sodium hypochlorite or nitric acid. The fibers can also be coated electrolytically by making the fibers the positive terminal in a bath filled with various electrically conductive materials. The surface treatment process must be carefully controlled to avoid forming tiny surface defects, such as pits, which could cause fiber failure.

Sizing

After the surface treatment, the fibers are coated to protect them from damage during winding or weaving. This process is called sizing. Coating materials are chosen to be compatible with the adhesive used to form composite materials. Typical coating materials include epoxy, polyester, nylon, urethane, and others.

The coated fibers are wound onto cylinders called bobbins. The bobbins are loaded into a spinning machine and the fibers are twisted into yarns of various sizes.

RECYCLABILITY

Carbon fiber products can be difficult to break down or recycle. It is possible to grind them down or break them down with very high temperatures or chemicals to recover the carbon fiber. However, the carbon fiber can be damaged in the process and they can also destroy the matrix resin materials in the composites.