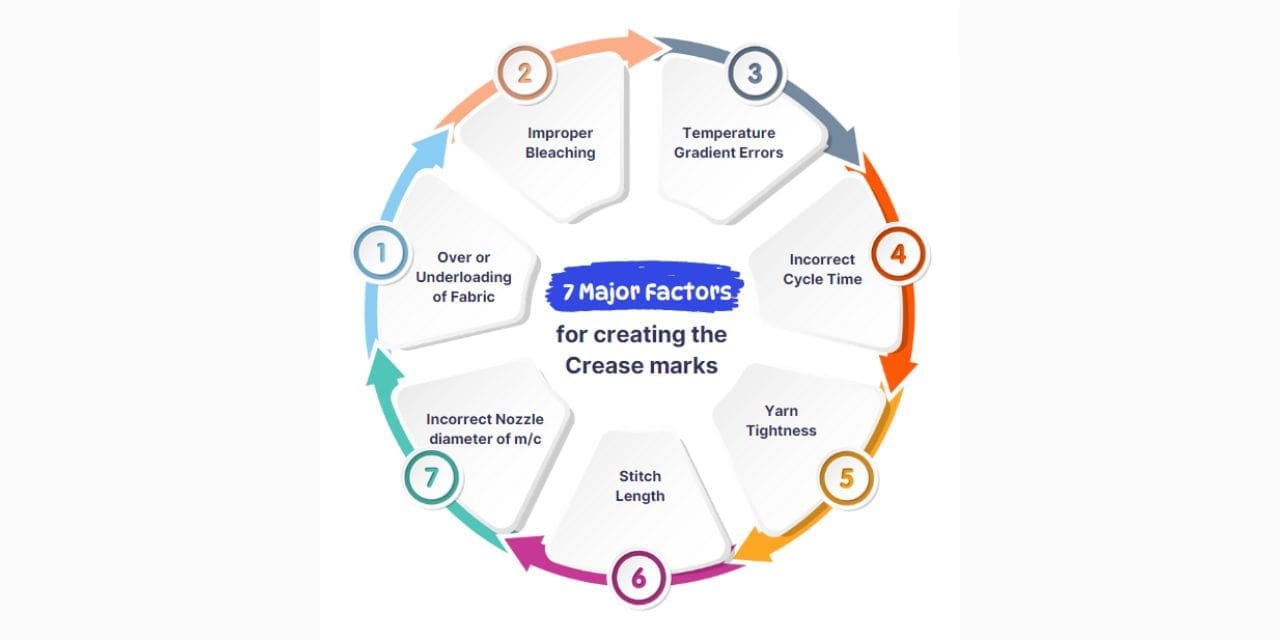

In textile manufacturing, crease marks are a major issue impacting fabric quality and businesses. Operational errors and material properties are common causes of creasing, leading to higher rejection rates and production costs. Understanding these factors is crucial for implementing effective strategies to prevent crease formation and maintain competitiveness in the market. Factors like fabric load, bleaching, nozzle diameter, and yarn tightness play a role in crease formation, requiring optimization of cycle time and storage solutions to minimize their impact.

Various factors contribute to the formation of crease marks on knit fabric during the dyeing process. Issues such as fabric overload or underload in the dyeing machine, improper bleaching, nozzle diameter and entry angle errors, high fabric loading speeds, temperature gradient errors, and tight knitting can all lead to creasing. Extended storage in compressed or folded conditions can allow wrinkles to set, leading to permanent crease marks.

Crease marks can be difficult to eliminate due to various factors, but there are several countermeasures that can help address this issue. Firstly, maintaining optimum yarn tension during knitting processes is crucial in minimizing crease formation. Monitoring and adjusting machine settings such as yarn tension can help achieve uniform fabric tension and reduce the likelihood of crease marks.

Additionally, implementing roll-wise fabric storage can help organize and minimize wrinkles during the storage process. Using a fabric roll device can ensure a more orderly storage process, reducing the chances of crease marks. Furthermore, increasing the diameter of the nozzle used during dyeing can also help prevent crease marks. Smaller nozzle diameters can lead to high load and excessive pressure during dyeing, resulting in crease marks.

Other measures such as using anti-creasing agents, adjusting stitch length, maintaining a temperature gradient, controlling cycle time, and using fatty acid-based softeners instead of silicone softeners can all help enhance fabric resistance to crease formation and prevent crease marks effectively.

Crease marks in textile products have a significant impact on businesses, leading to buyer dissatisfaction, increased production costs, and reduced profits. These creases can result in lower quality perceptions, negative brand image, and potential loss of sales. Efforts to eliminate crease marks often fail, leading to either rejection by buyers or acceptance with minor creases.