- New SustainableYarns.com platform to support the design and manufacture of sustainable carpets

- Announcing EqoYarn – a new low-impact solution added to the Eqo range

- Meet B.I.G. Yarns in Clerkenwell at The Order of St. John expo Stand D11, 23-25 May 2023, London

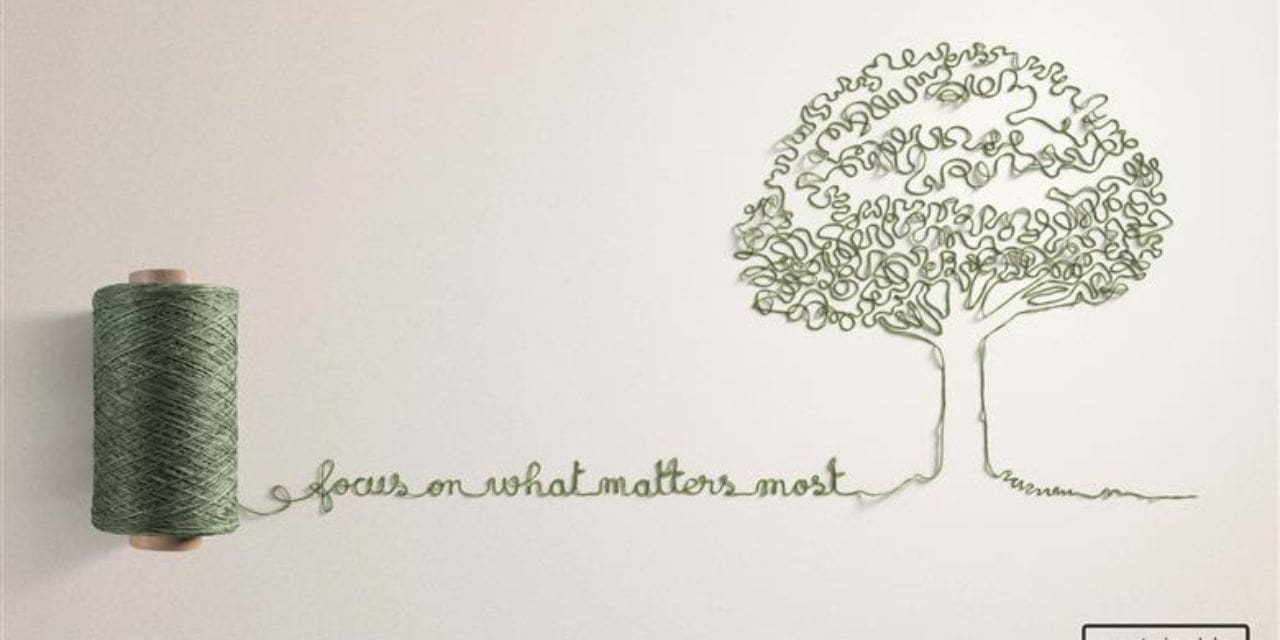

Wielsbeke, Belgium – May 17, 2023 – Join the sustainable yarns movement! B.I.G. Yarns today unveils its new “SustainableYarns” platform, with Clerkenwell Design Week visitors the first to be invited to get on board and focus on what matters most for the design and manufacture of sustainable soft floorings.

The expert in polyamide (PA) 1 step 3 ply yarns offers a range of options for manufacturers to introduce sustainable yarns into carpet solutions and reach sustainability targets faster and more efficiently.

“Yarn is the core material for carpets, and integral in contributing towards more responsible commercial, residential or automotive carpets. With our SustainableYarns online platform, we’re sharing a guide to our different market-ready options for more sustainable solutions, reducing the CO2 emissions of carpet products and helping to mitigate Climate Change. All this without compromising the quality and the unlimited colour and design possibilities our customers value from our yarn products,” says B.I.G. Yarns Global Sales Director, Glenn Hyzak.

The Sustainable Yarns range creates opportunities to design with recycled content yarn (EqoCycle), to work with renewable resources (EqoBalance), and, following the launch of new polyamide 6 (PA6) EqoYarn at Clerkenwell Design Week, to also leverage the low-impact value chain.

New addition EqoYarn is a new low-impact PA6 carpet yarn based on the most recent innovations in polymer production, which enable yarn manufacturers to lower their carbon footprint by nearly 50% and give carpet manufacturers more options to reduce their impact.

For its EqoYarn Bulk Continuous Filament (BCF) production process, B.I.G. Yarns has selected the few best-in-class partners that have made major steps forward in terms of sustainability, and reduced their greenhouse gas emissions thanks to continuous investments in process efficiency, green energy, heat optimization and waste reduction. The result is EqoYarn with a carbon footprint of 4 kg CO2 eq/kg yarns, which is a CO2 reduction of up to 50% compared to conventional PA yarns.

EqoBalance PA6 yarns enable customers to reach an even higher CO2 reduction of up to 75%. Manufactured with polymers made from renewable resources such as organic waste from cooking oil instead of virgin or fossil feedstock, these yarns have a carbon footprint of 1.98 kg CO2 eq./ kg yarns. They help carpet manufacturers to create products with an extremely low carbon footprint.

EqoCycle PA6 yarns are fully recyclable and incorporate 75% recycled content originating from recycled and regenerated PA6 granules. With a carbon footprint of 4.64 kg CO2 eq./ kg yarns, they deliver the same high-quality performance of virgin PA6 yarn with the benefit of 37% CO2 reduction. EqoCycle yarns offer carpet manufacturers a sustainable alternative to help reduce the ecological footprint of their products and move towards a circular economy without jeopardizing the end-product quality.

“B.I.G. Yarns is focused on leading the way in offering sustainable solutions, and to achieve this our focus is on optimizing production chains rather than using offsetting,” comments Emmanuel Colchen, General Manager, B.I.G Yarns. “We are reducing emissions from our own operations but because polymers, our raw materials, have the biggest impact on our CO2 emissions, it is crucial to engage supply partners to reduce emissions too by using bio-based materials. As a group, Beaulieu International Group wants to set the standard and reach a CO2 emission that is as low as possible, by offering the right product, based on sustainable parameters. This is part of the efforts to reach our Net Zero target by 2030.”

In addition to the different CO2-reducing options, B.I.G. Yarns’ customers can access an unlimited colour range to elevate their designs. Its BCF technology for polyamide yarns, twisted and heat-set yarns, one-colour to multi-colour, between 650 and 15000 dTex, along with its colour studio, are available to support their creation of unique and customised collections.