By NCFA TEAM

- Preamble

Rapid population growth leads to the utilisation of natural resources and the generation of enormous quantities of waste material. Waste management of agricultural by-products is vital to developing countries like India. Furthermore, the waste in many instances turn out to be wealth as a source of specific material as in the present case – a fibre source. Several researchers have focused on the utilisation of both organic and inorganic waste materials for the manufacture of composite panels and found improvement in the physical, mechanical, and thermal characteristics of composite panels.

Organic waste materials such as bagasse, jute, coir, and areca nut husk fibre were used for manufacturing of low-cost composite materials. Areca nuts, obtained from areca nut palms, consist of the husk of 15–30% by weight of raw areca nuts. Areca nut husk fibre is an agricultural waste that, if put to proper application, turns into wealth as it gives additional revenue generation. Presently, the waste does not contribute to the economy of areca nut plantations significantly. The use of areca nut husk fibre for various textile and allied applications especially as reinforcing material in the preparation of low-cost and lightweight composites provides utility value to areca nut husk fibre. Due to the sustainability of the material being made available, the use of the bye product has potential gain in utilising the natural resources, especially in India. The husk fibre of the Areca nut is used as a lightweight, economically reinforcing material in industries such as construction, vehicle manufacturing, and aircraft manufacturing. The husk fibre is also used in the preparation of hard boards, paper boards, cushions, and non-woven fabrics.

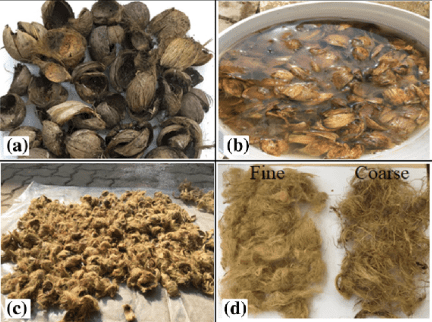

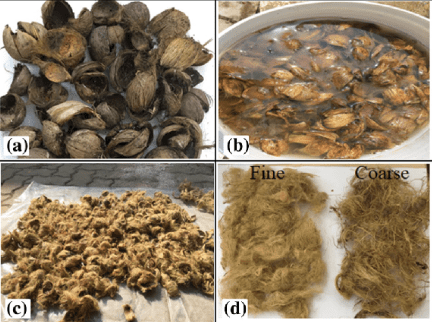

Fig. 2 (a) Dried areca nut husk, (b) soaking areca nut husk in alkaline solution, (c) drying of areca nut husk and (d) fibre extracted from areca nut husk.

- Botanical Information

- Areca catechu is a palm species that belongs to the family Aceraceae and is commonly known as betel nut.

- It is an extremely high potential, perennial, monocotyledonous species having properties of an angiosperm.

- It is native to the Philippines but is mainly grown in the tropical regions of the Pacific, Asia, and some parts of East Africa.

- Countries like Taiwan, Bangladesh, India, Maldives, Sri Lanka, Cambodia, and other tropical countries are the main cultivators of the palm tree.

- Agro Climatic Conditions for Cultivation

- To ensure a well-deep root system, the soil for cultivation should be deep with high organic carbon content.

- Laterite, red loamy, and alluvial soils are most suited for the cultivation of areca nuts.

- The pH range of soil should lie between acidic to neutral.

- It requires evenly distributed rainfall with a mean annual rainfall of 750-4500mm.

- It proliferates in the tropical regions with temperatures around 150C – 390C.

- The lifespan of the palm tree continues for 100 years, and fruiting for around 30-60 years.

- Statistics show that the annual world production of areca nuts is 1,073,000 tons, and approximately 2.5 g of areca husk could be extracted from every areca betel nut.

- In India, 90% of cultivation is contributed by Karnataka, Kerala, and Assam states.

- Name of areca nut plant in different regional languages

- English – Betelnut palm, Areca nut, Betel palm,

- Betel-nut, Supari palm, Pinang palm.

- Filipino – Bunga

- French – Arec cachou, Arequier

- German – Arecapalme, Betelnut palme

- Italian – Avellana d’India

- Thai – Maak mia

- Sinhala – Puwak

Fig.3 Different Constituents of Areca Nutshell

- Features of Areca Nut Husk Fibres

- It is an eco-friendly fibre as it is biodegradable, renewable and can be recycled.

- It shows good tensile and elongation properties and is water-absorbent.

- The coarse betel nut fibres hold good specific mechanical strength and have excellent toughness.

- The raw betel nut fibre has the highest fibre length.

- Fibres are rough, brittle, and stiffer due to the presence of lignin.

- The strength and fineness of the fibre is similar to cotton.

- It is lightweight, stringy and has a high strength-to-width ratio.

Table 1: Typical Mechanical and Chemical Properties of Areca Nut Husk Fibres

| Mechanical properties | Chemical composition | ||

| Length | Details | (%) | |

| Short | 18-29mm | Alpha cellulose | 53.20% |

| Medium | 30-38mm | Hemi cellulose | 30-64% |

| Long | 39-46mm | Lignin | 7-24.8% |

| Diameter | 0.28-0.89 mm | Ash | 4.4 – 4.8% |

| Elongation at break | 15±3% | Pectin and wax | A negligible percentage |

| Tensile Strength | 147-322 MPa | ||

Fig.4 Nonwoven fabric made with areca nut husk fibre

Fig.4 Nonwoven fabric made with areca nut husk fibre

Fig.5 Other applications of areca nut husk fibre & Leaf

- Uses

- It is used to make thick boards, pressed boards, fluffy cushions, and nonwoven fabrics.

- It is also used to make paper by blending areca nut and bamboo/banana pseudo-stem pulp.

- It can be used to make composites with different materials to enhance the usage of this fibre.

- The composites made up of areca nut fibre and epoxy can be used for marine applications, electrical, insulating components, lightweight components, the automobile industry and the chemical industry.

- It is used as a building material in villages and throughout Southeast Asia it is used for different construction purposes.

- Bibliography

- N. Muralidhar. Vadivuchezhian Kaliveeran. V. Arumugam, I. Srinivasula Reddy; “A “Study on Areca nut Husk Fibre Extraction, Composite Panel Preparation and Mechanical Characteristics of the Composites”; J. Inst. Eng. India Ser. D (2019), https://doi.org/10.1007/s40033-019-00186-1

- Chikkol Venkateshappa, S., Bennehalli, B., Gadde Kenchappa, M., & Ranganagowda, R. P. (2010). “Flexural behaviour of areca fibres composites”. Bio-Resources, 5(3), 1846–1858. https://doi.org/10.15376/biores.5.3.1846-1858

- Sunny, G., & Rajan, T. P. (2021). “Review on areca nut fibre and its implementation in sustainable products development”, Journal of Natural Fibers, 19(12), 4747–4760. https://doi.org/10.1080/15440478.2020.1870623

- Textile-coach. (2021, January 8). Betel Nut Fiber. https://www.textilecoach.net/post/betel-nut-fiber

- Orwa. (2009). Areca catechu. Agro forestree database 4.0. https://apps.worldagro-forestry.org/treedb/index.php?keyword=Fibre

- Gokarneshan, N., Sathya, V., Lavanya, J., Shabnum, S., Habeebunisa, & M. Anton, S. (2023). “A Review of Significant Advances in Areca Fiber Composites”. Intech Open. doi: 10.5772/intechopen.108028

- Sakshi Kamath, S. Dhanalakshmi and Basavaraju Bannehalli, “A review on Natural Areca Fibre reinforced Composite materials”; 2017. Portuguese Society of Materials (SPMP, (Pub) Elsevier Espana, S.L.U